manganese ore concentration magnetic china

Extraction and separation of manganese and iron from ferruginous ...

2019年1月15日 According to the U.S. Geological Survey (USGS) statistics of 2016, the global manganese ore reserve is about 690 million tons (metal basis), and 99.5% of

获取价格

Recovery of Manganese Ore Tailings by High-Gradient Magnetic

2017年8月16日 The Mn tailings were treated by HGMS at 12,500 G to obtain a Mn concentrate of 30% Mn with the recovery efficiency of 64%. The Mn concentrate could be

获取价格

A new metallogenic model for the giant manganese deposits in ...

2022年10月1日 The recently discovered multiple world-class Nanhuanian manganese (Mn) ore deposits at Datangpo of northeastern Guizhou province in southern China

获取价格

Studies on Beneficiation of Manganese Ore through

2020年6月20日 In the unsieved ground ore, manganese content of 45% was achieved with a recovery of 23% and Mn/Fe ratio of 19% at a magnetic intensity of 8500 Gauss.

获取价格

Mineralogical Characterization and Optimization of Fe and Mn

2021年3月26日 Ferromanganese ore from the Yunnan Province of China was investigated by subjecting it to reduction roasting, leaching, magnetic separation, hydrometallurgical

获取价格

Mineral Commodity Summaries 2022 - Manganese - USGS

Tariff: Item. Ores and concentrates: Containing less than 47% manganese Containing 47% or more of manganese Manganese dioxide High-carbon ferromanganese Ferrosilicon

获取价格

Manganese Data Sheet - Mineral Commodity Summaries 2020

Manganese ore was consumed mainly by eight firms with plants principally in the East and Midwest. Most ore consumption was related to steel production, either directly in pig iron

获取价格

Insight into Mineralogy of a Low-Grade Manganese Ore for

2022年3月15日 Because of the special magnetic susceptibility of these minerals, the magnetic separation method was chosen to improve the grade of manganese ore, and

获取价格

Security of Manganese Resources and Industrial Chain in China - CAE

2022年6月23日 This paper reviews the industrial supply chain of manganese ore resources and materials in China from five aspects: resource, smelting, material, product,

获取价格

Natural sources of iron and manganese in groundwater of the

2021年6月4日 Shallow groundwater resources in the lower Kelantan River Basin show anomalously high concentrations of iron and manganese. In some cases, other transition metals and metalloids such as arsenic are also present at elevated levels. Coupled mineral stability and aqueous geochemical models were used to determine the possible sources

获取价格

Minerals Free Full-Text Influence of Mineralogy on

2021年1月31日 Magnetic separation is often considered pertinent for manganese ore beneficiation when the ore is abundant with siliceous rich gangue mineral phases. However, the process is deemed to be

获取价格

Distribution Characteristics and Genesis of Iron and

2023年5月30日 Groundwater resources are an essential component of global water resources. Long-term consumption of groundwater exceeding the standard levels for iron and manganese can lead to chronic

获取价格

A sustainable reduction roasting technology to upgrade the

2021年2月15日 Reduction roasting of manganese ores is a known process; however, it is not yet commercialized mainly due to various techno-economic issues. The current research work presents results of a large-scale plant trial performed at a commercial Direct Reduced Iron making plant to upgrade low-grade ferruginous manganese ores (Mn: 25–32%,

获取价格

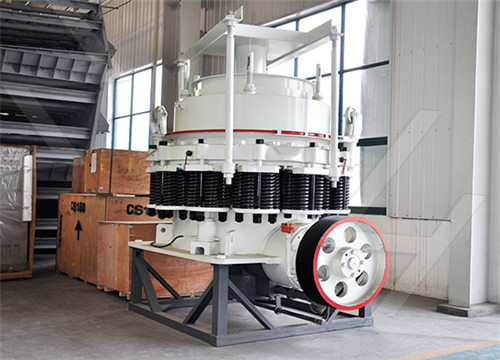

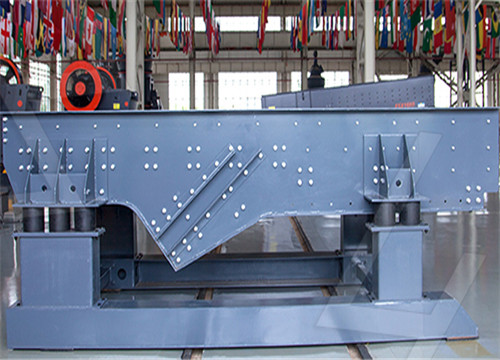

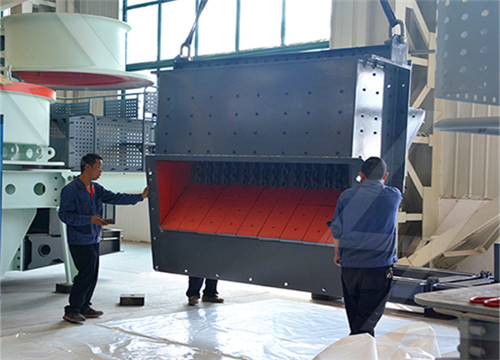

Manganese magnetic concentration process - Jinpeng Mining

Manganese ore processing technology is based on its different principles , there are many methods , now in China magnetic concentration is the most widely used in manganese ore processing technology , after rough concentration and selected concentration then get the concentrate .It is a high technological enterprise that integrated research ,

获取价格

Magnetic Fluid Separation SpringerLink

2023年5月14日 It can be used for the separation of nonferrous and precious metal ore (tin, lead, and gold ore, etc.), ferrous metal ore (iron, manganese ore, etc.), coal, and nonmetallic ore (diamond, potassium salts, etc.). In rock-mineral identification, magnetic fluid can replace dense liquid to separate mineral particles.

获取价格

1,2,3,4,5,6,* , Kai Zou 1,4, Tao Chen 1,4, Wenliang Xiong

2021年3月30日 concentration of manganese carbonate obtained by magnetic separation is higher than that of heavy concentrate, which is an important means of separating modern industrial manganese ore resources. With the complexity of selected ores, the research and devel-opment of an efficient magnetic separator should be strengthened [6,7]. (4) The

获取价格

Occurrence, distribution, and prediction of iron and manganese in ...

2021年7月31日 Based on the geological and hydrologic data, the generation, enrichment, and transportation of iron (Fe) and manganese (Mn) ions in Yimin open-pit mining area were investigated using water quality analysis of groundwater samples, Statistical Product and Service Solutions (SPSS) principal component analysis, and geostatistics analysis by

获取价格

Metals Free Full-Text Extraction of Manganese and Iron from a ...

2021年3月30日 In this research, the coarse manganese concentrate was collected from a manganese ore concentrator in Tongren of China, and the contents of manganese and iron in coarse manganese concentrate were 28.63% and 18.65%, respectively. The majority of the minerals in coarse manganese concentrate occur in rhodochrosite,

获取价格

Separation of Mn and Fe from a Manganiferous Iron Ore Using

2022年1月13日 The separation of manganese and iron from a manganiferous iron ore using horse dung (biomass) as reductant was investigated in a sulfuric acid solution, and 99.80% Mn and 17.76% Fe were extracted into the solution under these leaching conditions: 1 M sulphuric acid concentration, 120 g/L biomass, 1/10 solid to liquid ratio, 300 rev/min

获取价格

Separation of Fe and Mn from Manganiferous Iron Ores via

2019年8月1日 In this study, a process to separate manganese and iron from manganiferous iron ores by reductive acid leaching followed by magnetic separation was conceived and experimentally tested. In the leaching process, sulfuric acid was used as lixiviant and oxalic acid was used as reductant. The experimental results showed that the

获取价格

Extraction and separation of manganese and iron from

2019年1月15日 The manganese ore resources in China are about 43,000 kilotons ... Leaching efficiency of Fe increases with the acid concentration, which is as high as 84% in a 4 mol/L H 2 SO 4 solution (Nayl et al., 2011). ... The gangue minerals in the Fe-Mn ores are removed effectively from the magnetic manganese ferrites by multistage magnetic

获取价格

Insight into Mineralogy of a Low-Grade Manganese Ore for

2022年3月15日 Abstract In this study, the use of XRF, XRD and other instruments found that the manganese content in the ore was 14.53%, and the main forms were carbonate, iron manganese oxide and manganese oxide. Because of the special magnetic susceptibility of these minerals, the magnetic separation method was chosen to improve

获取价格

Effect of desliming on the magnetic separation of low-grade

and pre-concentration of manganese ore prior to the mag-netic separation. As reported in the literature, the flotation of siliceous manganese ore has been attempted; however, the adsorption mechanism has not been properly addressed [2,24−26]. Gravity separation studies involving jigs, shaking

获取价格

Separation of Fe and Mn from Manganiferous Iron Ores via

2019年8月1日 In this study, a process to separate manganese and iron from manganiferous iron ores by reductive acid leaching followed by magnetic separation was conceived and experimentally tested. In the leaching process, sulfuric acid was used as lixiviant and oxalic acid was used as reductant. The experimental results showed that the

获取价格

Extraction and separation of manganese and iron from

2019年1月15日 The manganese ore resources in China are about 43,000 kilotons ... Leaching efficiency of Fe increases with the acid concentration, which is as high as 84% in a 4 mol/L H 2 SO 4 solution (Nayl et al., 2011). ... The gangue minerals in the Fe-Mn ores are removed effectively from the magnetic manganese ferrites by multistage magnetic

获取价格

Insight into Mineralogy of a Low-Grade Manganese Ore for

2022年3月15日 Abstract In this study, the use of XRF, XRD and other instruments found that the manganese content in the ore was 14.53%, and the main forms were carbonate, iron manganese oxide and manganese oxide. Because of the special magnetic susceptibility of these minerals, the magnetic separation method was chosen to improve

获取价格

Effect of desliming on the magnetic separation of low-grade

and pre-concentration of manganese ore prior to the mag-netic separation. As reported in the literature, the flotation of siliceous manganese ore has been attempted; however, the adsorption mechanism has not been properly addressed [2,24−26]. Gravity separation studies involving jigs, shaking

获取价格

Thermochemical oxidation of methane by manganese oxides in

2023年6月24日 The powders and thin-sections of Mn ore from the Heqing Mn ore deposit were analyzed using a Bruker D8 ADVANCE X-ray diffractometer, with data collected over the 2θ range of 5°–75° during ...

获取价格

Virginia Energy - Geology and Mineral Resources - Manganese

The mined ore at this deposit contained about 46 percent manganese, 2 percent iron, and 8 percent silica on average (Watson, 1907). Tazewell, Bland, and Giles Counties Another important location for manganese mining in the western Valley and Ridge district is the Maxwell-Narrows area, stretching from Tazewell through Bland and into Giles ...

获取价格

Suspension magnetization roasting on waste ferromanganese ore

2022年1月1日 As a waste ferromanganese ore resource, unavailable due to conventional technology and thus hoarded in mass quantity, in which it functions as an invaluable recycling value. In the study, an efficient semi-industrial test for recycling manganese and iron was investigated by suspension magnetization roasting, and with the results

获取价格

Manganese - Element information, properties and uses Periodic

The main mining areas for manganese are in China, Africa, Australia and Gabon. The metal is obtained by reducing the oxide with sodium, magnesium or aluminium, or by the electrolysis of manganese sulfate. ... Manganese in the form of the black ore pyrolucite (manganese dioxide, MnO 2) was used by the pre-historic cave painters of the Lascaux ...

获取价格

Manganese: Nodules, Uses, Facts, Ore, Alloys, Metal - Geology

Manganese removes oxygen and sulfur when iron ore (an iron and oxygen compound) is converted into iron. It also is an essential alloy that helps convert iron into steel. As an alloy, it decreases the brittleness of steel and imparts strength. The amount of manganese used per ton of steel is rather small, ranging from 6 to 9 kilograms.

获取价格

Current situation of global manganese resources and

requirements in China, since 2015, China’s manganese ore production has been declining, and its share in the world has also continued to decline (Figure 3). 3.1.1 South Africa ... manganese ore concentration area, especially the metamorphic sedimentary manganese deposits hosted in the Paleoproterozoic Transvaal supergroup[12,13].

获取价格

Recyling manganese-rich electrolytic residues: a review

2023年4月8日 In China, manganese ore deposits are primarily concentrated in Guizhou, Guangxi, and Hunan provinces. ... the leaching concentration of manganese was still within the safe range under acidic conditions at a pH of 2, ... Elliott R, Barati M (2020) A review of the beneficiation of low-grade manganese ores by magnetic separation. Can

获取价格

Mineralogical Characterization of Manganese Oxide Minerals

2021年11月9日 The Guangxi Zhuang Autonomous Region is an important manganese ore district in Southwest China, with manganese ore resource reserves accounting for 23% of the total manganese ore resource reserves in China. The Xialei manganese deposit (Daxin County, Guangxi) is the first super-large manganese deposit discovered in China. The

获取价格

Evolution of Manganese Ore Genesis in the Earth’s ... - Springer

influence on manganese concentration in the primary sediments. The manganese deposits are spatially and, in many cases, genetically associated with carbonifer ous rocks, and this relation is traced even from the Early Precambrian (Archean Khapchan Group from the Anabar Shield, Graphite Group in Madagascar, Timskaya Group of the Kursk

获取价格

Manganese Statistics and Information U.S. Geological Survey - USGS.gov

Products for construction, machinery, and transportation are leading end uses of manganese. Manganese also is a key component of certain widely used aluminum alloys and, in oxide form, dry cell batteries. As ore, additional quantities of manganese are used for such nonmetallurgical purposes as plant fertilizers, animal feed, and colorants for ...

获取价格