lightweight fly ash aggregate machinery

Fly ash lightweight aggregates in high performance concrete

2008年12月1日 Lightweight aggregates have been manufactured by sintering fly ash and crushing the product into suitable sizes. These aggregates possess unique

获取价格

Fly Ash Utilization in Lightweight Aggregates for Sustainable ...

2018年12月31日 This study describes the development of new lightweight angular fly ash aggregate (FAA) and consequent comparison of properties of FAA with traditional

获取价格

Lightweight Aggregates From Fly Ash - ESCSI

2009年6月4日 There are three processes for producing lightweight aggregates using fly ash: sintering, hydro thermal, and cond bonded.Plants producing lightweight aggregate

获取价格

Preparation of non-sintered lightweight aggregates through co ...

2020年4月5日 This work investigates the feasibility of co-mechanochemical treatment of oil-contaminated drill cuttings (OCDC), circulation fluidized bed combustion (CFBC) fly ash, and quicklime to prepare non-sintered lightweight aggregates (NSLWAs). The NSLWAs with high cylinder compressive strength and low water absorption could be

获取价格

Sintered Fly Ash Light Weight Aggregate

The product is an excellent alternative to natural quarried aggregate, being strong, light and consistent. Sintered Flyash light weight aggregate substitutes natural stone aggregate/chips in Concrete, reducing dead

获取价格

A Review on the Manufacturing of Lightweight Aggregates

The saturated surface dry specify gravity of fly ash geopolymer artificial aggregate is 1.89 [18]. Other than that, the lower unit weight of cold bonded geopolymer lightweight aggregate can be obtained by using rice husk ash as source material [4]. The specific gravity of sintered fly ash aggregate is increased from 1.51 to 1.92 when it

获取价格

Applied Sciences Free Full-Text Properties of a Lightweight Fly Ash ...

2021年1月14日 Sintered fly ash aggregate is an artificial lightweight aggregate that is produced by expanding the pulverized fuel ash at approximately 1200–1300 °C in a rotary kiln. The particle shape of the sintered fly ash aggregate is mainly spherical, with a dense outer shell and highly porous inner structure.

获取价格

Fly Ash the Lightweight Aggregate Market - FEECO

Fly Ash the Lightweight Aggregate Market. In 2015, the global fly ash market was estimated to be valued at 40 billion USD. A recent industry analysis by Research Nester anticipates the market will reach an estimated 70 billion USD by the end of 2023 – a 7.1% CAGR owing to increasing urbanization and a boost in construction projects.

获取价格

Utilization of fly ash by pelletization process; theory, application ...

2000年7月1日 The material properties, pelletization process and machinery details are given in the sections below. ... The developed lightweight fly ash aggregates have suitable angularity with rough surfaces for better interlocking and excellent mechanical properties (toughness, hardness, abrasion and soundness), meeting the criteria of aggregate for ...

获取价格

Materials Free Full-Text The Effects of Various Concentrations of ...

2021年2月27日 The effects of synthesis parameters (6, 8, 10, 12, and 14 M) on the mechanical and microstructural properties of the fly ash geopolymer aggregate were studied. The fly ash geopolymer aggregate was palletized manually by using a hand to form a sphere-shaped aggregate where the ratio of NaOH/Na2SiO3 used was constant at 2.5.

获取价格

Recent advances in artificial aggregate production

2021年4月1日 Sintering, as one of the most commonly used methods to manufacture lightweight AAs was initiated in the 1950s in UK. Traditionally, granulated clay and fly ash are the most frequently used constituents to produce commercial sintered AAs, namely lightweight expanded clay aggregate (LECA) and sintered fly ash aggregate (Lytag)

获取价格

Recovery of Biomass Fly Ash and HDPE in Innovative Synthetic

2020年8月13日 Sustainable development principles aim to re-utilize wastes to reduce their impact on the environment. In this context, the present contribution shows preliminary results on the preparation of innovative synthetic lightweight aggregates, starting from biomass-derived fly ash and high-density polyethylene (HDPE), to be used in geotechnical

获取价格

Lightweight geopolymer fly ash sand: an alternative to fine aggregate

2021年1月1日 Another alternative could be use of sintered fly ash lightweight aggregate which is now commercially available for use in struct ural concrete with an upper ceiling on grade of concrete in Indian ...

获取价格

Production and Evaluation of Synthetic Lightweight Aggregates

2022年1月16日 This paper presents an attempt to obtain technically valuable lightweight aggregate produced from a mixture of fluidized bed fly ash and post-mining residues. The motivation to take up this study is a problem with the reasonable utilization of huge amounts of ashes produced by power plants in Poland. The ashes still produced and those stored

获取价格

The Use of Fly Ash and Lime Sludge as Partial Replacement of

2014年1月1日 R. Siddique, “Effect of fine aggregate replacement with class F fly ash on the mechanical properties of concrete,” Cement and Concrete Research, vol. 33, pp. 539-547, 2003. S. Ramesh, “Appraisal of vernacular building materials and alternative technologies for roofing and terracing options of embodied energy in buildings,” Energy ...

获取价格

STRENGTH PROPERTIES AND DURABILITY ASPECTS OF

The effect of basalt fibre on concrete made with sintered-fly-ash aggregates as coarse aggregates, a by-product of the processing of fly ash is studied in detail with respect to its strength ...

获取价格

Fly ash lightweight aggregates in high performance concrete

2008年12月1日 Abstract. Lightweight aggregates have been manufactured by sintering fly ash and crushing the product into suitable sizes. These aggregates possess unique characteristics that make them suitable for high strength and high performance concrete. Concrete produced using these aggregates is around 22% lighter and at the same time

获取价格

Production and Evaluation of Synthetic Lightweight Aggregates

2022年1月16日 This paper presents an attempt to obtain technically valuable lightweight aggregate produced from a mixture of fluidized bed fly ash and post-mining residues. The motivation to take up this study is a problem with the reasonable utilization of huge amounts of ashes produced by power plants in Poland. The ashes still produced and those stored

获取价格

The Use of Fly Ash and Lime Sludge as Partial Replacement of

2014年1月1日 R. Siddique, “Effect of fine aggregate replacement with class F fly ash on the mechanical properties of concrete,” Cement and Concrete Research, vol. 33, pp. 539-547, 2003. S. Ramesh, “Appraisal of vernacular building materials and alternative technologies for roofing and terracing options of embodied energy in buildings,” Energy ...

获取价格

STRENGTH PROPERTIES AND DURABILITY ASPECTS OF

The effect of basalt fibre on concrete made with sintered-fly-ash aggregates as coarse aggregates, a by-product of the processing of fly ash is studied in detail with respect to its strength ...

获取价格

Fly ash lightweight aggregates in high performance concrete

2008年12月1日 Abstract. Lightweight aggregates have been manufactured by sintering fly ash and crushing the product into suitable sizes. These aggregates possess unique characteristics that make them suitable for high strength and high performance concrete. Concrete produced using these aggregates is around 22% lighter and at the same time

获取价格

Synthesis of artificial aggregates and their impact on ... - Springer

2023年5月27日 The cost of making artificial aggregates is higher than that of producing natural aggregates as it requires unique machinery and trained human resources . ... Kockal NU, Ozturan T (2010) Effects of lightweight fly ash aggregate properties on the behavior of lightweight concretes. J Hazard Mater 179:954–965.

获取价格

Lightweight geopolymer fly ash sand: an alternative to fine

considered wisely while designing the light weight geopolymer fly ash concrete mix. In current study, Lightweight Geopolymer fly ash sand (LWGFAS) was prepared by using class F fly ash and alkaline activator solution. The fly ash used in the study was from NTPC Sipat, India. The specific gravity and Blaine ïs fineness of fly ash was 2.12 382 ...

获取价格

Strength of light weight concrete containing fly ash cenosphere

2023年4月17日 The in-place density (unit weight) of structural lightweight concrete is from 1440 to 1840 kg/m 3, while that of normal weight concrete is between 2240 and 2400 kg/m 3. Concrete strength for structural applications should be higher than 17.0 MPa. •.

获取价格

Influence of geopolymer aggregates on micro-structural and

2021年12月9日 This paper explores the physical, mechanical and durability characteristics of Fly ash—ground granulated blast furnace slag (GGBS) based Geopolymer aggregates include Specific gravity, impact value, crushing value, loss angles abrasion value, attrition value and water absorption respectively. Besides, scanning electron microscopy (SEM)

获取价格

Manufacturing process of the artificial lightweight aggregates

Artificial aggregates manufactured with fly ash, bentonite binder combination have 23.1MPa compressive strength for 10mm aggregate which is much lesser when compared with F21 type aggregate [33]. ...

获取价格

Making Concrete Pumpable Concrete Construction Magazine

2020年1月28日 Ruttura says the ideal is to “have at least 270 pounds of water per cubic yard, although we can pump it with down to about 230 pounds with a well-blended aggregate.”. Putzmeister A wide array of factors can impact concrete pumpability such as the dimension, shape, gradation, and volume of aggregates and fibers.

获取价格

Characteristics of lightweight fly ash aggregates produced

2011年1月1日 2.2. Preparation of lightweight aggregates. Harikrishnan and Ramamurthy have shown that the pelletization process parameters such as the speed and the angle of the pelletizer disk, moisture content and the duration of the pelletization strongly influence the properties of the fly ash aggregates produced [25].A pelletizer disc of 400 mm

获取价格

Ready Mixed Concrete - NSF

Fly ash, Plasticizers and superplasticizers 20900 2009 2000 33% 0% y 0.71 6+/-2 Natural sand, Batch water, Portland cement, Fly ash, Plasticizers and superplasticizers, Air entrainers 30050 2345 3000 20% 0% y 0.5 5+/-1 Coarse aggregate (crushed), Natural sand, Portland cement, Batch water, Fly ash, Plasticizers and

获取价格

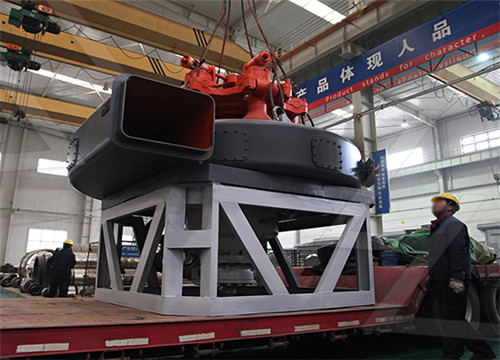

Fly Ash Processing Equipment - FEECO International Inc.

Process equipment for conditioning fly ash or converting it for beneficial reuse, with process development, as well as parts service support available ... Fly Ash and the Lightweight Aggregate (LWA) Market. 3D Model of a FEECO Rotary Kiln for Sintering Fly Ash. Disc Pelletizer (Pelletiser) for Fly Ash Lightweight Aggregate (LWA) Production ...

获取价格

Experimental studies on light weight concrete using LECA material

2023年1月1日 Durability of lightweight concretes with lightweight fly ash aggregates. Constr. Build. Mater., 25 (2011), pp. 1430-1438, 10.1016/j.conbuildmat.2010.09.022. View PDF View article View in Scopus Google Scholar [20] S.N. Manu, P. Dinakar. Mix design and Properties of fly ash waste light weight aggregates in structural light weight

获取价格