crushing grinding platinum

OVERVIEW OF PGM PROCESSING - Anglo American Platinum

Platinum Group Metals (PGMs) are recovered through underground and open pit mining from poly-metallic sulphide ores containing PGMs, Nickel, Copper and other metals: •

获取价格

Characterizing the behaviour of platinum group minerals in a

2021年6月1日 This paper introduces a methodology to determine the gravity-recoverable platinum group minerals (GRPGMs) of a stream, and behaviour of platinum group

获取价格

Unveiling Platinum: Mining and Processing Wonders

2023年6月9日 Once extracted, gold ore is often processed through crushing, grinding, and chemical treatments such as cyanidation to separate the gold from the ore matrix. In

获取价格

(PDF) Potential Processing Routes for Recovery of

2017年11月6日 PDF The beneficiation of platinum group metals (PGMs) from pristine (unweathered) sulfide ores has conventionally been

获取价格

Direct leach approaches to Platinum Group Metal (PGM) ores and ...

2015年7月1日 Ore is first ground by conventional multistage crushing and ball milling, or by semi-autogenous grinding (SAG), and then smelted. The matte is

获取价格

Recovery and Enrichment of Platinum Group Metals from Spent

2023年2月11日 The overall process of pyrometallurgy generally includes shearing, crushing, grinding, batching, ball pressing, smelting, and enrichment, refining and other

获取价格

Modeling and control of a crushing circuit for platinum

2018年1月25日 With the availability of a validated crushing circuit model of an Anglo Platinum plant, this simulation based approach becomes viable. This paper discuss different control strategies tested in an ...

获取价格

Pilanesberg Platinum Mine: Crushing its targets

2019年10月21日 Pilanesberg Platinum Mine: Crushing its targets. Situated on the Western Limb of South Africa’s Bushveld Complex, the open cast Pilanesberg Platinum Mine has delivered 10 years of steady PGM

获取价格

Energy Consumption in Mining Comminution - ScienceDirect

2016年1月1日 Whereas crushing is usually a dry process, grinding is usually performed wet to provide a slurry (liquid) feed to the chemical concentration process [15]. With rock reduced to a manageable size by crushing, grinding mills then reduce the rock even more to a particle size that makes chemical processing viable.

获取价格

PGM Ore Processing at Impala's UG-2 Concentrator - SGS

The feed to Impala’s UG-2 plant contains 22 - 24% Cr2O 3, or roughly 50% chromite. The aluminium silicate mineralisation includes primary magnesium alumino-silicates such as feldspars, pyroxenes and chlorite, and. comprise roughly 70% of the PGM (platinum group minerals) in the UG-2 plant feed, the remainder largely being alloys of iron, lead ...

获取价格

Effects of grinding media on the flotation performance of cassiterite ...

2021年7月1日 1. Introduction. Crushing and grinding are necessary for the processing of minerals that coexist closely with gangue minerals (Gong et al., 2020, Wills and Finch, 2016).Crushing-grinding provides the materials with a suitable particle size and the sufficient liberation of useful minerals for the subsequent separation process (Li and Gao,

获取价格

Introduction to Mineral Processing or Beneficiation - Sepro Labs

2018年1月12日 The crushing and grinding process will produce a range of particles with varying degrees of liberation (Figure 2). Any particles that exceed a target size required for physical separation or chemical extraction are returned to the crushing or the grinding circuit. Figure 2. Breaking of larger material to smaller pieces result in particles with ...

获取价格

Unveiling Platinum: Mining and Processing Wonders

2023年6月9日 Gold is typically extracted using various methods, including placer mining, hydraulic mining, and heap leaching. Once extracted, gold ore is often processed through crushing, grinding, and chemical treatments such as cyanidation to separate the gold from the ore matrix. In contrast, platinum mining involves processes such as crushing, milling ...

获取价格

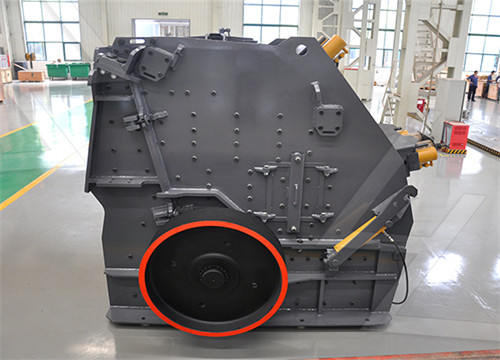

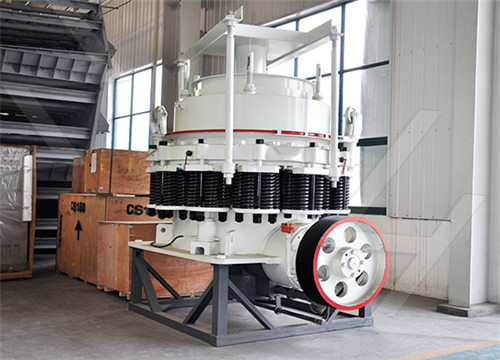

SBM mining machine for South African platinum group of metals

The SBM crushing plant for platinum group of metals include jaw crusher, impact crusher, cone crusher and son on. For the feature of platinum group of metals, the SBM cone crusher is the ideal crusher to processing. It is a new type and high efficiency cone crusher which collects mechanical, hydraulic, electrical, automation, intelligent ...

获取价格

Characterizing the behaviour of platinum group minerals in a grinding

2021年6月1日 This paper introduces a methodology to determine the gravity-recoverable platinum group minerals (GRPGMs) of a stream, and behaviour of platinum group minerals (PGMs) in a ball mill-cyclone circuit. The GRPGM is determined by a modification of the method developed for gravity-recoverable gold (GRG). Mineral behaviour in the

获取价格

crushing milling flotation Mining Quarry Plant

2013年4月1日 Platinum ore is fed into milling and crushing circuits, BCjobs.ca – BC's Career, Employment Job Posting Site Project Engineer: Crushing,Milling,Flotation Reference ID: 189 Company: HMW Recruiters Inc. Date Posted: March 19, 2013 (Closing May 18, 2013)

获取价格

Grinding down energy consumption in comminution

2019年6月21日 According to the Coalition for Eco-Efficient Comminution, comminution – the process of crushing and grinding ore – is by far the most energy consuming step in the mining process. It accounts ...

获取价格

Grinding Mills — Types, Working Principle Applications

2018年8月17日 Stage 2 — Crushing Screening. ... (primary grinding mill) ... Examples include use in gold, copper and platinum mines with applications also in the lead, zinc, silver, alumina and nickel ...

获取价格

Grinding Mill Liners - 911 Metallurgist

2015年8月6日 Rubber liners absorb the impact of the larger grinding media and thus protecting – the mill structure and prolonging it’s life. Weight: Rubber weighs about 15% of an equivalent volume of steel. This means that a rubber liner system reduces the load on the mill structure and also reduces the basic power draw.

获取价格

Study on Grinding Behavior Characteristics under Low-Speed Grinding

2023年6月8日 In order to explore the crushing mechanism of minerals, this paper attempts to eliminate the throwing effect of media and study the grinding characteristics of minerals only under the action of abrasion force. In this paper, the method of removing the throwing state of media is to adjust the mill to a lower rotational speed, so that the

获取价格

(PDF) The Effect of HPGR and Conventional Crushing on the

Comparative high pressure grinding rolls (HPGR) and cone crusher pilot-scale tests were conducted using Upper Group 2 (UG2) platinum-bearing ore in order to determine the impact of micro-cracks in HPGR products toward energy requirements in ball

获取价格