main shaft speed of hammer crusher pdf

DESIGN, FABRICATION AND TESTING OF A LABORATORY

that the main shaft speed of 913.5 rpm transmitted by a belt drive from a three horse power electric motor is suitable to crush effectively. A comparison of the products of the newly

获取价格

Design and Analysis of Rotor Assembly of Hammer Mill

5.3 Machine Productivity. The crushing productivity increased with increasing feeding rate, screen holes diameter and hammer speed. The machine productivity ranged from 150 to

获取价格

(PDF) Design and Performance Evaluation of a Stone Crusher

2021年10月7日 The fabricated stone crusher was tested and the actual capacity was found to be 301 kg/h with a through-put efficiency of 75.4 %. The crushed products were

获取价格

Construction Working and Maintenance of Crushers for

working of the crusher is as under. The main shaft of the crusher is journaled in the spider bearing and in the eccentric bearing assembly. The spider bearing fixes the position of

获取价格

DEVELOPMENT OF A HORIZONTAL SHAFT HAMMER MILL

2019年12月23日 The power required to deliver the through put efficiency of the machine was determined to be 5,480W. The rotor speed is obtained as 1289.1 rpm. The major

获取价格

Design and Evaluation of Crushing Hammer mill

The obtained data showed that the consumed energy decreased with increasing feeding rate, screen holes diameter and hammer speed. The consumed energy ranged from 7.5 to 21 W.h kg -1 with hammer rotor

获取价格

International Journal of ChemTech Research

The Design and analysis of shaft and rotor assembly for hammer mill crusher of capacity 0.1 (100kg/hr) tones per hour transmitting 20 B.H.P and a speed of 750 rpm. The design

获取价格

DESIGN AND EVALUATE OF A SMALL HAMMER MILL

Based on the power ratings and output shaft speed of the existing crushing and grinding machines it was found that the main shaft speed rotating speed of 2000 rpm transmitted by a belt drive from a 1 kilowatt electric

获取价格

DESIGN AND ANALYSIS OF IMPACT CRUSHERS - National

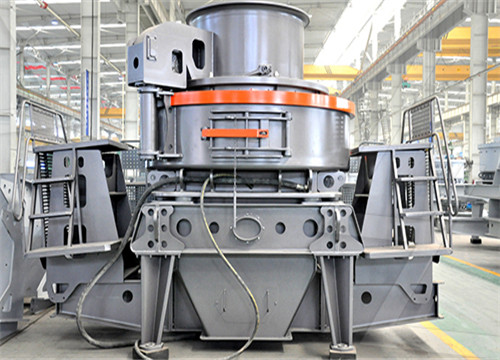

1.3.1 Horizontal Shaft Impact Crusher 3 1.3.2 Vertical Shaft Impact Crusher 4 ... easily controlled by varying the rotor speed. each crusher can accommodate several ... 2-

获取价格

What Type of Crusher Is Best for Primary Crushing?

2021年3月25日 Hammermills can be used as a primary crusher in many types of aggregate and industrial applications, including limestone, marble, shale, gypsum, phosphate, bauxite, aluminum dross, uranium, cryolite,

获取价格

Design of a Rotary Blade Glass Pulverizing Machine

2020年10月1日 shaft to which is attached 3 steel blades separated at 1200 to their centre, ... of pulverized glass particles through it and a 1hp high speed motor which drives the shaft. The ... a screw feeder, belts and pulleys, hammer mill-shaft, pulveriser shaft as well as an electric motor for power transmission. The design concept integrated the milling and

获取价格

(PDF) DEVELOPMENT OF A HORIZONTAL SHAFT HAMMER MILL CHAPTER

2.6.6 Hammer Tip Speed The speed of the hammer at its tip furthest away from the rotor is known as the tip speed. This is critical for proper size reduction; the tip speed is calculated by multiplying the of the drive shaft speed in revolutions per minute by the circumference of the hammer tip arc (Kim, 2002).

获取价格

Impact crusher structure, working principle and features

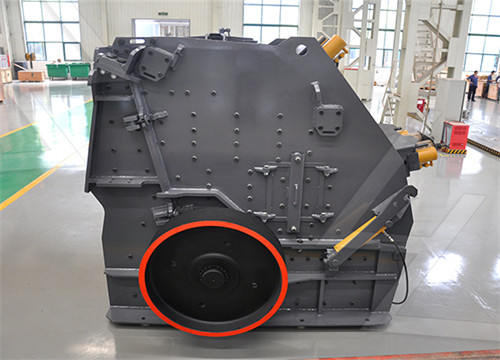

2021年9月2日 1.1 Impact crushers can be divided into two types according to the number of rotors: single-rotor and double-rotor impact crushers. 1.2 The structure of the single rotor impact crusher (Figure 1) is relatively simple and consists mainly of the rotor 5 (strike plate 4), the impact plate 7 and the machine body. The rotor is fixed to the main shaft.

获取价格

SANDVIK 700 RANGE HORIZONTAL SHAFT IMPACTORS (HSI)

The all-new 700 range of Horizontal Shaft impact crushers offers new levels of safety and efficiency. Developed to comply with new EU legislation, you can configure these smart, modular crushers to ... No. of hammer bars per row 1 1 3 Rotor Speed Range rpm 555 to 656 398 to 445 Max feed size G mm 600 900 1000 in 24" 36" 39 3/8" Total weight (2 ...

获取价格

Finite Element and Multibody Dynamics Analysis of a Ball Mill Glass Crusher

2023年3月16日 Fladvad and Onnela [] studied the influence of jaw crusher parameters on the quality of primary crushed aggregates.In the hammer crusher (Figure 2), hammerheads of high wear resistance and strength are attached to the tip of a rotor placed inside a well-sealed, noiseless, and fixed casing.As the hammerheads rotate with a high speed, they

获取价格

Intro to Size Reduction - Schutte Hammermill

perhaps 3 to 4 large pieces. Conversely, if you hit it with the same hammer at a rapid speed, it will break into many more, much smaller pieces. Hammer Size: Strike a water glass with a butter knife, and it will break into a few large pieces. Strike the same glass with a sledge hammer, and it will shatter into 1000+ pieces. In short:

获取价格

Crushing Technologies - thyssenkrupp Polysius

Discover our durable crushers on our landing page: crushing-technologies. The TITAN® Double-Shaft Hammer Crusher is used for crushing medium-hard rock. For wet limestone, wet marl, clay, chalk, gypsum and similar raw materials. The mammut® crusher is uncomplicated and compact in design, rugged in its construction, extremely powerful ...

获取价格

Hammer Crusher Design PDF Crusher Mills, Cone Crusher, Jaw Crushers

DESIGN AND ANALYSIS OF A HORIZONTAL SHAFT IMPACT CRUSHER. β=specific particle size depending on the crusher design and granulate properties. ... Fig.4 A Single particle just after with the rotor bar of a hammer crusher [1] 10.

获取价格

Design and Evaluation of Crushing Hammer mill - Academia

Each hammer was drilled at the bottom (hole of 10 mm), to enable to be put it into position on the hammer shaft. Mass of each hammer = 49.52 g, number of hammers 10, so the centrifugal force exerted by the hammer = 596.21 N (upward). 2.2.5 Main shaft In order to transfer the power to the main shaft of the hammer mill, the various members (such ...

获取价格

DEVELOPMENT OF A HORIZONTAL SHAFT HAMMER MILL CHAPTER

2019年12月23日 The actual capacity was obtained to be 301 kg/h after the performance evaluation of the machine, and it has a 98 % material recovery rate and 75.25 % machine efficiency. The machine has a ...

获取价格

DEVELOPMENT AND TESTING OF A HAMMER MILL

the shaft P 490 W Weight of hammer Wham mer 0.47 N Centrifugal force exerted by the hammer C.F 244.04 N Diameter of hammer shaft D 8.7 mm Weight of hammer shaft Ws 0.243 N Maximum bending moment Mb (max) 20.54 Nm Diameter of main shaft d 16 Mm Hopper: It is pyramidal in shape and it was made from 1.8 mm thick plate. It was

获取价格

DESIGN AND EVALUATE OF A SMALL HAMMER MILL

The crusher uses a more efficient method of grinding feed grain – a combination of impact and cutting, in contrast to a hammer mill that grinds with a free impact of hammers. ... output shaft speed of the existing crushing and grinding machines it was found that the main shaft speed rotating speed of 2000 rpm transmitted by a belt drive from ...

获取价格

selection and purchasing guide of hammer crusher

The double rotor crusher has separate drive motors for each shaft. The weight of the replacable impact hammers is in the range of 20 to 200 kg each, depending upon the crusher size. The chemical composition of the hammer steel is: c = 1.0- 1.4 %. Si = 0.4- 1.0 %. Mn = 12.0-14.0 %. p = 0.06%.

获取价格

DEVELOPMENT OF A HORIZONTAL SHAFT HAMMER MILL CHAPTER

2019年12月23日 The actual capacity was obtained to be 301 kg/h after the performance evaluation of the machine, and it has a 98 % material recovery rate and 75.25 % machine efficiency. The machine has a ...

获取价格

DEVELOPMENT AND TESTING OF A HAMMER MILL

the shaft P 490 W Weight of hammer Wham mer 0.47 N Centrifugal force exerted by the hammer C.F 244.04 N Diameter of hammer shaft D 8.7 mm Weight of hammer shaft Ws 0.243 N Maximum bending moment Mb (max) 20.54 Nm Diameter of main shaft d 16 Mm Hopper: It is pyramidal in shape and it was made from 1.8 mm thick plate. It was

获取价格

DESIGN AND EVALUATE OF A SMALL HAMMER

The crusher uses a more efficient method of grinding feed grain – a combination of impact and cutting, in contrast to a hammer mill that grinds with a free impact of hammers. ... output shaft speed of the existing

获取价格

selection and purchasing guide of hammer crusher

The double rotor crusher has separate drive motors for each shaft. The weight of the replacable impact hammers is in the range of 20 to 200 kg each, depending upon the crusher size. The chemical composition of the hammer steel is: c = 1.0- 1.4 %. Si = 0.4- 1.0 %. Mn = 12.0-14.0 %. p = 0.06%.

获取价格

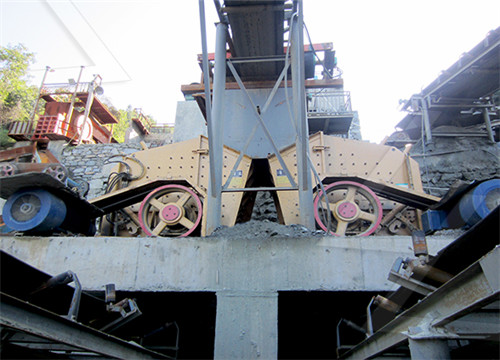

double-shaft hammer crushers - ThyssenKrupp

In double-shaft hammer crushers, the crushing of the feed material is mainly performed by the rotating hammers between the rotors and on the anvil. From top: Hammer axle extraction device for TITAN ® crusher, type 96D180 TITAN® crusher, type 80D160, with hammer axle extraction device Grate basket trolley

获取价格

(PDF) DESIGN AND EVALUATE OF A SMALL HAMMER MILL

PDF On Dec 18, 2015, Hanafi A Radwan and others published DESIGN AND EVALUATE OF A SMALL HAMMER MILL Find, read and cite all the research you need on ResearchGate ... the main shaft speed ...

获取价格

Impact Crusher - an overview ScienceDirect Topics

Impact Crusher. The impact crusher (typically PE series) is widely used and of high production efficiency and good safety performance. The finished product is of cube shape and the tension force and crack is avoided. Compared with hammer crusher, the impact crusher is able to fully utilize the high-speed impact energy of entire rotor.

获取价格

Hammer Crusher Parts, What You Need to Know

2022年9月1日 The rotor is an important part of the hammer crusher. The rotor is mainly composed of a main shaft, a hammer disc, a pin shaft and a hammer head. There are evenly distributed pin holes on the disc, and the hammer head is suspended by a pin shaft. The axial movement of the head is fixed on the 2nd end of the pin shaft with a lock nut.

获取价格

Hammer Crusher Working Principle Hammer Crusher Parts

2020年10月15日 The working principle of hammer crusher. Hammer crusher mainly breaks materials by the impact of hammers. The material entered into the working area of the crusher is crushed by high-speed hammers. The crushed material obtains kinetic energy from the hammers, and then it impacts on the crushing plate and grate screen at

获取价格

Gyratory Crusher - an overview ScienceDirect Topics

The gyratory crusher shown in Figure 2.6 employs a crushing head, in the form of a truncated cone, mounted on a shaft, the upper end of which is held in a flexible bearing, whilst the lower end is driven eccentrically so as to describe a circle. The crushing action takes place round the whole of the cone and, since the maximum movement is at the

获取价格

HP Series cone crushers – High performance

HP Series cone crushers bring together the optimal combination of crusher speed, throw, crushing forces and cavity design. As the name suggests, these proven and reliable universal crushers deliver High Performance in quarrying and mining applications. They deliver predictable and consistent production, and they are trouble-free, easy ...

获取价格

Hammer mill design calculation pdf - Australian Guidelines User

2023年5月16日 Hammer Crusher Design PDF. . main shaft speed of hammer crusher pdf – Stone . coal crusher design in south africa pdf, coal crusher machine . May 26, 2015 More details crusherexporters pdf hammer mill design calculation design hammer mill, jurnal gaya yang terjadi pada hammer mill.

获取价格

DESIGN, FABRICATION AND TESTING OF A LABORATORY

hammers was used to avoid the rotor or the hammers from getting stocked in case a hammer comes in contact with a material it cannot break at first impact. Design theories and Calculations Determination of Shaft Speed To calculate the shaft speed the following parameters are used. 1 2 2 1 N N D D Spolt, 1988 (1) Where N 1

获取价格

Industrial Solutions Impact crushers - ThyssenKrupp

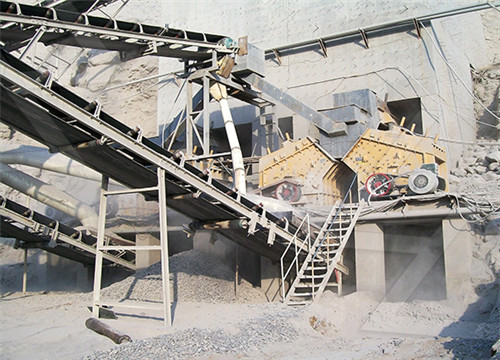

Stationary single-shaft impact crusher fed by two apron feeders at Cementos Progreso S.A., Guatemala Type PB 200/250 CR Throughput rate 1,100 t/h Mobile impact crusher with hydraulic walking mechanism at Martin Marietta, Texas, USA Type PB 250/300 CR Throughput rate 4,500/2,700 t/h Mobile wheel-mounted impact crusher

获取价格