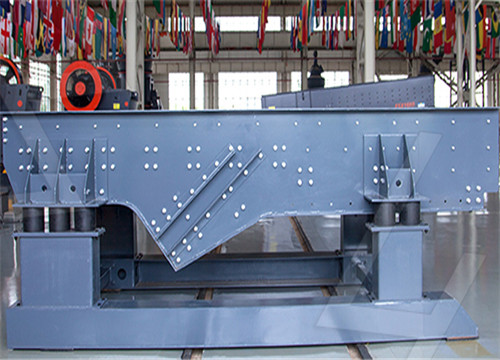

trolley with vibrating screen

Trolley-Mounted Vibrating Screen for Filtering

Trolley-Mounted Vibrating Screen for Filtering is a high-efficiency separation device, widely used in the screening and filtration of particles, powders and other substances in the

获取价格

进一步探索

7 troubleshooting tips for vibrating screen common A GUIDE TO VIBRATING SCREEN AND FEEDERS Hawk Vibrating screen working principle screening efficiencyWhat is the Screening Capacity of Vibrating Screen per AreaHow to deal with dust from vibrating screen Haiside

Types of Vibrating Screens: A Complete Detailed Guide

Rotary Vibrating Screen. The rotary vibrating screen is one of the most sought-after screening machines for material classification. It can be used for impurity separation,

获取价格

进一步探索

Manual Book Vibrating Screen PDF Bearing Types Of Vibrating Screen and How It Works - JXSC Machine

Vibrating Screens (Gyro Screens): Understanding Their

Vibrating screens play a role in the efficient separation of materials in industry. Let's understand vibrating screens working, types, applications benefits.

获取价格

Industrial Vibrating Screens - Advantages Its Uses

Lower Operational CostsLess MaintenanceImproved Material ProcessingHigher Screening EfficiencyConclusionAmong a plethora of screening equipment available in the machinery market, the vibrating screens proffer the most durable solution to control the flow of higher feed. With this being said, vibrating screens functions at its peak on a consistent flow rate. The same screener can also uphold the backflow of materials which requires a slower feed.

Welcome Campden Instruments

Contact us, we're ready to help! sales@campdeninstruments. +44 1509 814790. Online Form.

获取价格

Manufacturer of : Cablel Reeling Drums, Cable Drag Chain,

Collector Column, Festoon Trolley, Vibrating Feeders and Screen Spares. Other Details Compaction Table: Heavy duty for maximum loads, Standard or custom made to specification, Speed and impact adjustable , compaction tables can be supplied. It is most are both speed and force adjustable and Heavy-duty construction

获取价格

Vibrating Screen Working Principle - 911 Metallurgist

2015年7月26日 When the smaller rock has to be classified a vibrating screen will be used. The simplest Vibrating Screen Working Principle can be explained using the single deck screen and put it onto an inclined

获取价格

Industrial Vibration Motors ATO

120W Explosion Proof Vibration Motor, 4 pole. $1,171.69. SKU: ATO-EPNM-VBB-34. Sell explosion proof vibration motor at low price, 120W, 4 pole, 1400rpm, 380V vibrating motor provides a powerful source of vibration for the vibrating feeder, vibrating screen, vibrating blanking, and vibrating conveyor. Quick View.

获取价格

Martin Screen Vibrators

Martin Engineering M3536-05/07 4 MARTIN® Screen Vibrators Installing Vibrator Mounting vibrator onto screen IMPORTANT Read entire section before beginning work. This manual provides instructions for installations onto vibrating screens only. For other installations, call Martin Engineering or a representative. Use vibrator mount kit P/N 36468 ...

获取价格

Manufacturer of : Cablel Reeling Drums, Cable Drag Chain,

Collector Column, Festoon Trolley, Vibrating Feeders and Screen Spares. Other Details Compaction Table: Heavy duty for maximum loads, Standard or custom made to specification, Speed and impact adjustable , compaction tables can be supplied. It is most are both speed and force adjustable and Heavy-duty construction

获取价格

Linear vibrating screen Haiside

A linear vibrating screen is a type of screening equipment that utilizes linear motion to convey and separate different materials. It consists of a screen frame, a screen mesh, a vibration motor, and several supporting springs. The material to be screened is fed into the screen frame from the inlet, and as the screen vibrates, the material is ...

获取价格

McLanahan How To Size and Select a Vibrating Screen for an

2022年2月15日 Vibratory Screens come in a variety of sizes. They can range from 4’ to 12’ wide and 6’ to 32’ long. The width of the screen determines the carrying capacity of the screen deck, while the length of the screen determines the overall efficiency of the screen. Typically, the length of the screen is 2.5 to 3 times the size of the width.

获取价格

Coal Handling Plant In Thermal Power Plant

2016年11月13日 Roller Screens / Vibrating Screens; They are used for screening of fine, coarse and wet coal. The fine coal sizes are less than 20 mm. Components and Working of roller screen; Flap Gate; They are provided in transfer chute to channelize the route of coal. They are equipped with electrically operated actuators. Rack And Pinion Gate

获取价格

Vibrating Screens Types, Benefits and More DPH Engineering

2022年12月1日 This means that the benefits of both vibration types are combined in a horizontal screen. Horizontal screens have a stroke range of 14–20 mm and typically run at a stroke of 16–18 mm and a spinning speed of 750 rpm. Between 0.2 and 0.25 meters per second, materials move through the screening medium.

获取价格

Vibrating Screen - Vibrating Screen Sifter Manufacturer from

We are the proficient manufacturer of Vibrating Screen Machine that has high screening capacity. Widely regarded for its durability. This product finds a vast application in power stations, mines, chemical industries, and coal dressing as well. In addition to this, our range of vibrating screens is efficient in offering a hassle free performance.

获取价格

Dynamics Behavior Research on Variable Linear Vibration Screen

2014年1月1日 Liu C.-S., Ji L.-Q., and Wei Q., “Dynamic analysis of vibrating screen beam based on power balance,” Journal of China University of Mining and Technology, vol. 39, no. 3, pp. 330–334, 2010. ... Item saved, go to cart . Purchase 24 hour online access to view and download content. Article - $36.00 Add to cart ADD TO CART Added to cart. Checkout

获取价格

Stepwise shape optimization of the surface of a vibrating screen

2021年10月1日 The structure of a real vibrating screen is particularly complicated and mainly comprises a screen box, screen mesh, and vibration exciters. A simplified three-dimensional model of the vibrating screen, shown in Fig. 1, is established to reduce the complexity but realize the actual screening effect.Additionally, the sieving process in the

获取价格

Nine things you need to know regarding vibrating screens

2022年3月30日 Vibrating screens are designed to last between 5-10 years with excellent and regular skilled maintenance. The drive beam and side plates will last up to 7-10 years, depending on corrosive conditions. The deck beams, stringers and cleats up to 3 years and infeed and discharge components up to 5 years depending on screen loading and wear

获取价格

Vibrating Screen - Vibrating Screen Sifter

We are the proficient manufacturer of Vibrating Screen Machine that has high screening capacity. Widely regarded for its durability. This product finds a vast application in power stations, mines, chemical industries, and coal

获取价格

Dynamics Behavior Research on Variable Linear Vibration Screen

2014年1月1日 Liu C.-S., Ji L.-Q., and Wei Q., “Dynamic analysis of vibrating screen beam based on power balance,” Journal of China University of Mining and Technology, vol. 39, no. 3, pp. 330–334, 2010. ... Item saved, go to cart . Purchase 24 hour online access to view and download content. Article - $36.00 Add to cart ADD TO CART Added to cart. Checkout

获取价格

Stepwise shape optimization of the surface of a vibrating screen

2021年10月1日 The structure of a real vibrating screen is particularly complicated and mainly comprises a screen box, screen mesh, and vibration exciters. A simplified three-dimensional model of the vibrating screen, shown in Fig. 1, is established to reduce the complexity but realize the actual screening effect.Additionally, the sieving process in the

获取价格

Nine things you need to know regarding vibrating screens

2022年3月30日 Vibrating screens are designed to last between 5-10 years with excellent and regular skilled maintenance. The drive beam and side plates will last up to 7-10 years, depending on corrosive conditions. The deck beams, stringers and cleats up to 3 years and infeed and discharge components up to 5 years depending on screen loading and wear

获取价格

Vibratory Screeners Cleveland Vibrator

Cleveland Vibrator's vibratory screeners are used to separate materials by particle size, remove small amounts of oversized or fine material, or remove excess liquid from finished products. Our selection includes pneumatic or electromechanically powered units available with single or double decks for materials between 20 micron up to 4 inches.

获取价格

New Used Vibrating Screens For Sale Surplus Record

Get email updates for newly added Vibrating Screens. New Listing Alert. 18" x 36" Rotex #241A-MS/MS, screener, Carbon Steel, #15652. Federal Equipment Company Cleveland, OH. 866-74... (Show) 866-740-5490. Category: Vibrating Screens. Seller: Federal Equipment Company. Location: Cleveland, OH.

获取价格

Variable elliptical vibrating screen: Particles kinematics and ...

2021年11月1日 1. Introduction. Coal is one of the most important fossil energy sources in the world [1], [2], [3].In 2019, coal consumption accounted for 57.7% of the total national energy consumption in China [4].Although coal has greatly contributed to the development of the world economy and industrial production, smoke and harmful gases formed due to

获取价格

Dynamic design theory and application of large vibrating screen

2009年9月1日 The vibrating screen improved production effect of single machine and is suitable for medium drainaging of raw coal, ore and other materiel. The structure of CWS3675 large vibrating screen with hyperstatic net-beam structure is shown in Fig 2. Fig. 1. Hyperstatic net-beam structure Fig. 2. Model of vibrating screen 3.

获取价格

Basic concepts of vibrating screens: What they are, what they

Also called simply screens, a vibrating screen is formed by a vibrant chassis that supports in its interior one or several surfaces or elements of screening. The screens serve to classify the different particles by size, starting from a bulk product in a continuous process. The inlet material (the raw product) advances from the part where the ...

获取价格

Study on screening performance and parameter optimization of vibrating

2021年9月22日 In this paper, the dewatering and screening process of vibrating-dewatering screen is studied by the combination of simulation test and physical experiment. The simulation model of dewatering screening process is established by the method of computational fluid dynamics (CFD) and discrete element method (DEM).

获取价格

A new study on dynamic adjustment of vibration direction angle

2020年8月19日 The vibration direction angle is a critical parameter for vibrating machines, which has an important influence on the screening performance of the vibrating screen. 7,8 In the actual production, especially under the conditions that different screening materials have significant differences in properties, the fact that the vibration direction angle can be

获取价格

Controlled synchronization of a vibrating screen driven by two

2023年11月21日 The kinetic energy of the vibrating system is as follows: (1) with In Eq (), m is the quality of the shaking table and motors.J p is the rotational inertia of the shaking table. m 1 and m 2 are the masses of the two eccentric rotors (ERs) and the ERs are driven by motors. J 1 and J 2 are the rotational inertia of two motors. x i and y i are the

获取价格

Analysis of the dynamic forces acting on a vibrating screen and

2021年5月1日 Vibrating screens are equipment used in various industries, such as mining, steel and food. Although it is simple to install vibratory equipment on a support structure, it is necessary to consider the static and dynamic forces caused by vibration. The present work aims to perform a dynamic analysis of a vibrating screen and measure the

获取价格

A review on the advanced design techniques and methods of vibrating

2019年4月1日 A large vibrating screen is crucial to advancing the large scale coal preparation for the clean and efficient utilization of coal. A comprehensive review of advanced design techniques and methods for a vibrating screen have been presented. Almost 71% of all the literature were published during last five years. (2)

获取价格