crosys mill roll

(PDF) Cross Rolling: A Metal Forming Process

2015年6月1日 PDF The chapter deals with cross rolling where the workpiece is rotated by 90° in the rolling plane after each rolling pass.

获取价格

Cross Rolling: A Metal Forming Process SpringerLink

The chapter begins with basics of metal rolling, and later on focuses on cross rolling. A short introduction to texture and its representation is presented followed by an overview of

获取价格

Cross-roll piercing and cross helical rolling QForm

A characteristic feature of cross-roll piercing (rotary tube piercing) and cross helical rolling (three-roll skew rolling) is that metal continuity

获取价格

Basical Characteristics of Pair Cross Mill. National Technical ...

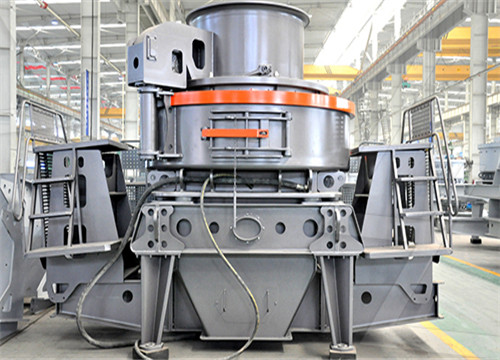

As a new rolling mill capable of freely controlling the shape and crown of rolled materials, a 'pair cross type' rolling mill has been developed. In that mill, roll groups, each

获取价格

Pair Cross Type Rolling Mill for Hot Rolling - ResearchGate

2015年4月28日 A pair cross type rolling mill has been developed for the requirements to control the shape and crown of hot-rolled strips. [1] The upper rolls and lower rolls are

获取价格

(PDF) Thin Strip Profile Control Capability of Roll

2013年11月1日 A new type of rolling mill has been developed that improves transverse gage profile and flatness of hot rolled strip as well as permitting schedule-free rolling.

获取价格

Modernization of Helical Rolling Technology in a Multi-Roll Mill

2022年7月26日 An analysis of the helical rolling process shows that the change in the axial speed of the roll along the length of the groove of the cross-roller mill doe.

获取价格

Features of roll cross wedge rolling mill - Alloy Wiki

2021年10月18日 The roll cross wedge rolling mill is the most widely used of the three types of rolling mills: its main advantages are as follows: (1) High productivity, generally

获取价格

Roller Mills Roll Crushers CPM

Roskamp roller mills and roll crushers deliver a consistent, uniform grind for every application imaginable. Engineered to give you precise particle size control, Roskamp roller mills and crushers are built on a strong, solid

获取价格

Everything you need to know about flatteners and levelers for coil ...

2002年10月10日 The mills deliberately crown their work rolls slightly larger in the center to allow for deflection and compression under load. The amount of roll crown that is added is a compromise, a best guess. In addition, mills can control the gap profile by bending these huge rolls or by expanding them with hydraulic pressure like a huge steel balloon.

获取价格

Theoretical Analysis of Rolling Force during Cold

2023年5月24日 The work roll crossing combined with roll shifting for asymmetrical and symmetrical rolling mills: PC: The pair-cross mill, in which the backup roll and work roll axes of each top and bottom are

获取价格

Rolling Technology and Theory for the Last 100 Years: The

At the time when the past basic research and development flowered, development of many new type rolling mills with the crown-shape control function were reported. 72,73,74,75,76,77,78) A pair cross rolling mill with a big effect of profile control for hot rolling mills was put to practical use, 79) which became a standard rolling mill for the ...

获取价格

(PDF) Progress and prospect of rolling technology - ResearchGate

2012年11月1日 22, 41 The most distinct technology among them is the skewed rolls that can expand the distance between the inner faces of the flange continuously by changing the rolling distance and cross angle ...

获取价格

Forging vs. Rolling: Understanding the Differences MachineMFG

2023年8月7日 Forging vs Rolling. (1) The mechanical properties of forgings in the axial and radial directions are more consistent compared to rolled products. This means that forgings have a much higher degree of isotropy, resulting in a longer lifespan compared to rolled products. The figure below illustrates the metallographic diagram of eutectic

获取价格

Teaching an old piercing mill new tricks - The Fabricator

2008年12月2日 Many seamless tube producers in North America use cross-roll piercing mills built in the 1950s that were based on designs from the1930s. While it would be advantageous to replace such aged equipment, that isn't always necessary. A minor equipment upgrade can do wonders. Improving the bar steadiers—the devices that hold

获取价格

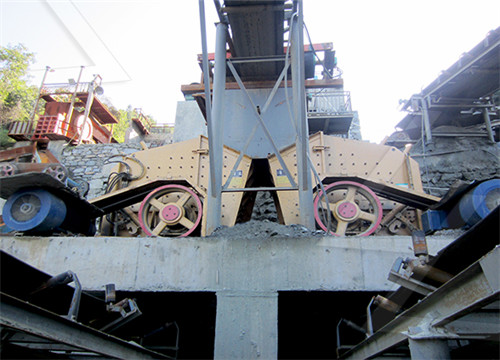

Rolling of steel and major equipment in a Cross-country Rolling Mill ...

2019年9月16日 There are usually two types of rolling stands which are commonly used in the cross country rolling mills. These stands are 2-high stands, and 3-high stands. This classification of stands is based on the mode of arranging rolls in the housings. Typically, a 2-high stand consists of 2 rolls, arranged one above the other.

获取价格

Metal Rolling - Manufacturing Process

Rolling is most often, (particularly in the case of the conversion of an ingot or continuous casting), performed hot. At a rolling mill, blooms and slabs are further rolled down to intermediate parts such as plate, sheet, strip, coil, billets, bars and rods. Many of these products will be the starting material for subsequent manufacturing ...

获取价格

Work Roll Choke for Pair Cross Rolling Mill - Google Patents

The present invention relates to a work roll choke of a pair cross rolling mill used for controlling the shape of a plate, and more particularly, to a pair cross rolling mill capable of minimizing a change in rolling load even when a thrust load is generated in a working roll of a pair cross rolling mill. It is an object to provide a work roll choke.

获取价格

4-High Rolling Mills Metal Processing Machinery - American Steel

4-High Rolling Mills. Four-high rolling mills can be put in tandem, two to seven stands, instead of a reversing mill. They can be equipped with load cells to tell the separating force and hydraulic or mechanical screw downs, depending if it is hot or cold rolling. Sometimes mechanical screw downs are preferred when there is a risk of fire.

获取价格

Cross Grain Services

Rollers. All Rollers in the Cross range of Roller Mills are manufactured in house. This leaves the customer with peace of mind when it comes to quality and backup service. Tubular Rollers are made from heavy duty tube steel which is turned and grooved in the Cross Factory. The Shafts in the rollers are made from the highest quality EN24T steel.

获取价格

Seabeam Multibeam Theory Operation - MBARI

We would like to show you a description here but the site won’t allow us.

获取价格

Work Roll Chock of Pair Cross Mill - Google Patents

2002年12月23日 The present invention relates to a work roll choke of a pair cross mill used for controlling the shape of a plate in a steel mill, and more particularly, a change in the rolling load even when a thrust load is generated in the work roll of a pair cross mill. It relates to a work roll choke of a pair cross rolling mill that can minimize the.

获取价格

4-High Rolling Mills Metal Processing Machinery - American Steel

4-High Rolling Mills. Four-high rolling mills can be put in tandem, two to seven stands, instead of a reversing mill. They can be equipped with load cells to tell the separating force and hydraulic or mechanical screw downs, depending if it is hot or cold rolling. Sometimes mechanical screw downs are preferred when there is a risk of fire.

获取价格

Cross Grain Services

Rollers. All Rollers in the Cross range of Roller Mills are manufactured in house. This leaves the customer with peace of mind when it comes to quality and backup service. Tubular Rollers are made from heavy duty tube steel which is turned and grooved in the Cross Factory. The Shafts in the rollers are made from the highest quality EN24T steel.

获取价格

Seabeam Multibeam Theory Operation - MBARI

We would like to show you a description here but the site won’t allow us.

获取价格

Work Roll Chock of Pair Cross Mill - Google Patents

2002年12月23日 The present invention relates to a work roll choke of a pair cross mill used for controlling the shape of a plate in a steel mill, and more particularly, a change in the rolling load even when a thrust load is generated in the work roll of a pair cross mill. It relates to a work roll choke of a pair cross rolling mill that can minimize the.

获取价格

High-performance Product Series For Steel

Double-row tapered roller bearings Inside diameter: 200~717.55mm. Bearings developed to manage the axial load of roll necks in rolling mills. A large contact angle is used to create a structure that. Sealed type four-row tapered roller bearings. Inside diameter: 220~800mm.

获取价格

Basics of Rolling and Rolling Mills – IspatGuru

2013年5月30日 Fig 4 Roll configurations in rolling mills. Two-high mill roll configuration – This is the most commonly used rolling mill configuration. In this configuration, there are two horizontally mounted rolls. The rolling mill motor drives either both rolls (top and bottom) or only one roll (normally the bottom roll) with the top roll rotating due to the

获取价格

Flatness in coil processing operations: New turns in the leveling

2001年8月16日 A cold mill can get less than 15 I-units of flatness. Coming off a temper mill, material may have less than 10 I-units. With a roller leveler, tension-assisted leveler, or tension leveler, the number may be 5 I-units, and possibly less than 1 I-unit. That is a big difference. Leveler Maintenance Options

获取价格

Rolling of Steel in small and medium sized Rolling Mills

2017年6月9日 A rolling mill of cross country type consists of several roll stands so arranged that the work piece is never in more than one roll stand at the same time. Since the roll stands are located side-by side, the work piece is transferred laterally to the roll bites of the various stands. In many of the cross country mills, the rolling of work piece ...

获取价格

Manufacturing large shafts by a novel flexible skew rolling

2021年10月5日 Another flexible rolling process is the three-roller skew rolling method which can be divided into two types: copy skew rolling (Fig. 1b) and CNC skew rolling (Fig. 1c).Copy skew rolling is originated from the former Soviet Union by Zerikov (1948) [15, 16], in which a copy plate is used to control the motions of tapered rollers.With the

获取价格

ROLLING-(A Brief Guide To Rolling And Rolling Mills)

Spread the love. Rolling is the process of plastically deforming metal by passing it between the roles. The rolling process is basically used for reducing the cross-sectional area of the metal stock. (The width is the same but there is a significant reduction of thickness). It is the most widely used forming process and it provides high ...

获取价格

Rolling Mills for sale listings - MachineTools

WATERBURY FARREL 12 HI SENDZIMIR REVERSING ROLLING MILL STOCK # 14136. Rolling Mills. For sale: a used 24" 12 high reversing Waterbury Farrel Sendzimir rolling mill (Stock # 14136). This machine manufactured in 1978 and upgraded in 2009, is ideal for processing copper and Cu-alloys.... Capacity (W): 25.984 in.

获取价格

Introduction to Rolling Process - Cambridge University Press

2 Principles and Applications of Metal Rolling (ii) Shape of the rolled product- flat, sections or hollow sections rolling. (iii) Direction of rolling- lengthwise, transverse, and skew rolling. (iv) Mode of rolling mill operation- continuous (unidirectional), and reverse rolling, where direction of rotation of rolls are reversed. When two rolls of equal diameter and with axis

获取价格

A comprehensive review on incremental deformation in rolling

2022年2月15日 Flat rolling. Flat rolling [] is one of the most basic forms of rolling and it is extensively used to produce flat sheets and strips.As depicted in the book, “Cold Rolling of Steel” [], it was first used by Leonardo Da Vinci to roll lead by employing a hand-cranked mill.Even after several decades since its introduction, the fundamentals of rolling for the

获取价格

4th Generation PC Mill Promoting DX (Digital Transformation)

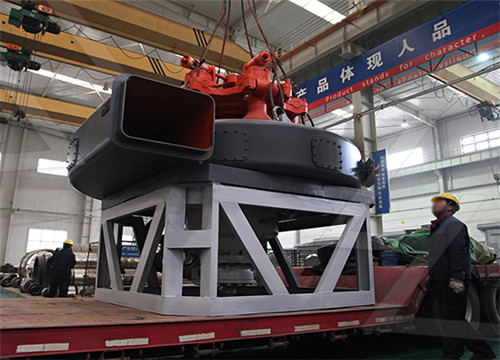

the many technologies developed to realize these needs, the key for hot rolling equipment is a hot rolling mill with high ability to control the cross-section shape of the strip. Primetals Technologies has been developing a hot rolling mill called the Pair Cross Mill (PC Mill) that has the capability to address current needs.

获取价格