difference between pyro and grinding unit cement plants

(PDF) A Review on Pyroprocessing Techniques for

2020年8月17日 The pyroprocessing process in kilns and the grinding technologies therefore have to be optimized for best processing. This

获取价格

A Review on Pyroprocessing Techniques for Selected Wastes Used

AbstractIntroductionCalcinationConclusionsData AvailabilityAcknowledgmentsPyroprocessing is an important stage in cement manufacturing. In this process, materials are subjected to high temperatures so as to cause a chemical or physical change. Its control improves efficiency in energy utilization and hence enhances production for good quality assurance. Kilns used in cement manufacturing are c在hindawi上Protus Nalobile, Jackson Muthengia Wachira, Joseph Karanja Thiong’o, Joseph Mwiti Marangu

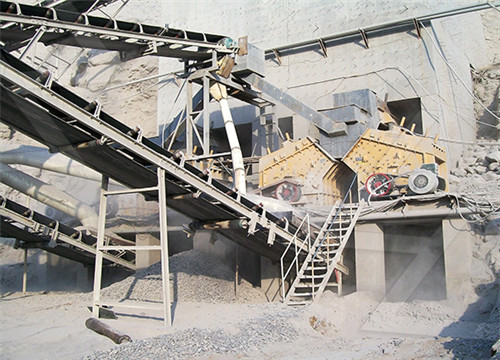

Cement Grinding Plant Overview Cement Grinding Unit AGICO

2019年10月11日 The cement grinding plant also called cement grinding unit, is used to grind clinker into qualified cement. With the development of the cement industry,

获取价格

进一步探索

Cement Plant Operation Handbook - [PDF Document]Project Report on cement grinding unit Manufacturing

Analysis of material flow and consumption in cement

2016年1月20日 The mass balance was examined for clinker production and across the boundary of the kiln system, which included the pyro-processing (unit 3), kiln (unit 4),

获取价格

EVERYTHING YOU NEED TO KNOW ABOUT ESTABLISHING

2020年5月22日 A 1.0 metre wide belt conveyor with a capacity of 800 tonnes per hour (TPH) will be installed at one side of the quay. This belt conveyor which will be a

获取价格

PyroProcessing in cement Industry - INFINITY FOR CEMENT

Guideline. • Chain surface: 19m2/t for oval chains vs. 22-25 m2/t for round chains. • For small kilns, ratios are always lower than for larger kilns. • Ratios are higher for dry kiln

获取价格

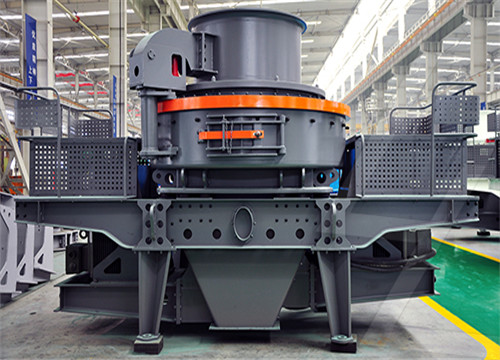

Cement Grinding Unit Cement Grinding Plant

Cement grinding unit, or called cement grinding plant, cement grinding station is an individual step in the cement production line. In the grinding plant, the cement clinker is added with the proper amount of mixed

获取价格

Pyroprocessing - KHD Humboldt Wedag

Pyroprocessing. The pyroprocess is the central element to the clinker-making process. Without heat – and lots of it – the raw meal would not react to create the cementitious material that is so important to modern life. But

获取价格

Energy benchmarking of cement industry, based on

2017年7月1日 In current study, a modern cement plant has been simulated and analyzed using Energy Integration concepts. Due to the difference between process and utility

获取价格

Pyro processing cement kiln bypass dust: Enhancing clinker phase ...

2020年10月30日 CBPD is often classified as cement kiln dust (CKD); but, the two are not the same and should be differentiated. CBPD is collected from the bypass only while CKD

获取价格

A Beginners Guide to Pyro-Processing - FEECO

Direct- VS. Indirect-Fired Rotary Kilns Dryers. For over a century, rotary equipment has been widely accepted as a preferred means for the pyro-processing of bulk solids, offering distinct advantages over

获取价格

Clinkerization - an overview ScienceDirect Topics

The grinding process differs depending on the pyro-processing process used. The feed to the kiln is called “raw meal.” ... This grinding unit produced only PPC cement with a capacity utilization of 112.96%. ... Plant P8: This plant

获取价格

Cement Production Process Cement Manufacturing

2020年8月25日 Cement grinding: The clinker is taken from the clinker silo and sent to the feed bin where it is mixed with gypsum and additives before entering the cement grinding plant. In the cement grinding process,

获取价格

Clinkerization - Cement Plant Optimization

The liquid percentage at 1450 0 C can be estimated using the formula. % Liquid content (1450 0C) = 3.0 x A+2.25 x F+S. Where A=Al 2 O, F=Fe 2 O 3, S= MgO+K 2 O+Na 2 O+SO 3 In Clinker. The normal range of liquid phase is 22-27%. Burnability is a reference value for raw meal indicating how difficult it is to burn.

获取价格

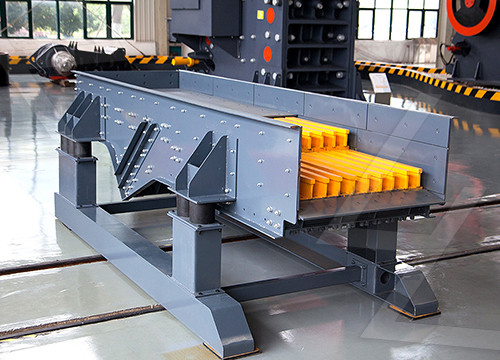

Energy-Efficient Technologies in Cement Grinding IntechOpen

2016年10月5日 The energy consumption of the total grinding plant can be reduced by 20–30 % for cement clinker and 30–40 % for other raw materials. The overall grinding circuit efficiency and stability are improved. The maintenance cost of the ball mill is reduced as the lifetime of grinding media and partition grates is extended. 2.5.

获取价格

cement plant report PDF - SlideShare

2014年1月19日 The capacity of the 6,00,000 tons plant increased by another 10,00,000 tons, making it the largest plant in West Bengal. The new grinding unit, Durga Hitech Cement, has one ball mill of 165 TPH capacities. This environment-friendly project, commissioned in 2005-06, utilized thermal power station fly ash to produce PPC.

获取价格

Peru - Cement industry news from Global Cement

2023年9月29日 Peru: Invercem has successfully commissioned its new 220,000t/yr Pisco grinding plant in Ica Department. Management News has reported that the plant cost US$30m to build. Cemex Peru will supply clinker for use in cement production at the plant. Invercem plans to supply cement produced at the plant to the Cusco market under the

获取价格

Global strategies and potentials to curb CO2 emissions in cement ...

2013年7月15日 In a cement plant, 90% of total input energy is consumed in the pyro-processing unit including pre-heater tower, calciner, kiln and coolers (Holderbank Inc., 1993). In this unit feed stream passing through pre-heater, calciner and the kiln is gradually heated from 50 °C to 1450 °C and then by air coolers is cooled down to 100 °C ( Khurana

获取价格

Hydraulic Roller Press -

Our Hydraulic Roller Press offers flexible feed material grinding. Equipped with high-quality wear protection, our Hydraulic Roller Press can withstand the most abrasive feed materials. Its solid-forged, single piece rollers with oil lubricated spherical bearings ensure premium grinding capability, top-of-class availability and utmost reliability.

获取价格

Separators - KHD Humboldt Wedag

From lowering costs to reducing environmental footprint, separators need to achieve high efficiency while lowering energy consumption. At KHD, we have a long history of innovation in separator technology. That tradition is part of our DNA and the basis for our continued technical development. Serving a range of applications from raw materials to cement, as

获取价格

Clinkerization Process - an overview ScienceDirect Topics

Scope for making and designing green cement plants. The cement industry is consciously making efforts in various areas ... The clinker output from the pyroprocessing unit is either sent to the grinding unit or exported to other cement plants or exclusive grinding units. Such clinker exports can cause variations in the baseline SEC.

获取价格

Differences between Clinker Grinding Plant and Cement Plant ...

2023年2月13日 Investment situation. In terms of investment, clinker grinding plants are typically less expensive to build and maintain compared to cement plants. This is due to the smaller scale of clinker grinding plants, which require less equipment and fewer personnel to operate. The smaller scale also means that clinker grinding plants are often more ...

获取价格

Cement Plant - an overview ScienceDirect Topics

Figure 1. Overview of SeqHENS framework. The studied cement plant has an average annual clinker production of about 5600 t/d. The kiln line is a common dry process, and the raw material moisture is about 2-3%. The estimated drying demand for the raw material is about 300 kJ/kg clinker.

获取价格

Analysis of material flow and consumption in cement

2016年1月20日 The recycle rate of waste gas discharged from the clinker production system is remarkably higher than that of the raw meal and cement grinding system. In the surveyed cement plant, 1.21 t of limestone, 0.09 t of silica, and 5.81 t of air are required to produce one ton of cement (P.O.42.5); meanwhile, 4.79 t of waste gas is discharged into

获取价格

Clinkerization Process - an overview ScienceDirect Topics

Scope for making and designing green cement plants. The cement industry is consciously making efforts in various areas ... The clinker output from the pyroprocessing unit is either sent to the grinding unit or exported to other cement plants or exclusive grinding units. Such clinker exports can cause variations in the baseline SEC.

获取价格

Differences between Clinker Grinding Plant and

2023年2月13日 Investment situation. In terms of investment, clinker grinding plants are typically less expensive to build and maintain compared to cement plants. This is due to the smaller scale of clinker grinding

获取价格

Cement Plant - an overview ScienceDirect Topics

Fuels, burnability and characterization of cement raw meal. Vipin Kant Singh, in The Science and Technology of Cement and Other Hydraulic Binders, 2023. 6.4.6.1 Preblending of coal. Cement plants receive coal from more than one source, and even from the same source of supply, there are wide fluctuations in the ash content. Such fluctuations upset

获取价格

Analysis of material flow and consumption in cement

2016年1月20日 The recycle rate of waste gas discharged from the clinker production system is remarkably higher than that of the raw meal and cement grinding system. In the surveyed cement plant, 1.21 t of limestone, 0.09 t of silica, and 5.81 t of air are required to produce one ton of cement (P.O.42.5); meanwhile, 4.79 t of waste gas is discharged into

获取价格

Energy benchmarking of cement industry, based on

2017年7月1日 Cement industry is considered as an energy intensive industry, owing to the huge amount of heat consumed in pyro-process unit.There are many conventional methods around, which can be applied to carry out energy targeting in a cement production plant, including conceptual, mathematical or even hybrid. However, full application of

获取价格

Energy and exergy analyses for a cement ball mill of a new

2020年5月1日 Altan et al. [25] investigated the effect of both closed and open circuit on the pre-grinding performance of a cement ball mill (CBM) unit with a high pressure grinding rolls. The results demonstrated that closed-circuit enhanced the overall efficiency of the two-compartment cement ball mill at the same final product fineness by decreasing the ...

获取价格

Review on vertical roller mill in cement industry its performance ...

2021年1月1日 Cement clinker is made by pyro processing of kiln feed into the preheater-kiln system ... Now a days Ball mills and HPGR are installed together as a common unit. As per European cement research academy's project “Future grinding technologies”, out of 1036 orders of grinding mills in 5 years, 58% were for Vertical Roller mill and 40% were ...

获取价格

Sustainable transition towards biomass-based cement industry: A

2022年7月1日 Cement is manufactured by calcination of calcium, silica and alumina sources such as limestone, clay and sand [4].Generally, these raw materials are locally sourced and undergo several sequential operations such as quarrying, homogenising of raw meal, preheating, calcination, clinkerisation, cooling, grinding, storage and dispatch.

获取价格

Energy consumption assessment in a cement production plant

2015年6月1日 The type of cement production process in the studied cement plant is typical dry process Portland cement and consists of three major steps. In the first step, certain portion of clay and limestone are blended together and then the mixture is crushed to form a powder. The raw material mills in the studied plant are of the roller mills type.

获取价格

Cement Manufacturing Process Phases Flow Chart Cement

2012年8月30日 Cement Manufacturing Process Phase II: Proportioning, Blending Grinding. The raw materials from quarry are now routed in plant laboratory where, they are analyzed and proper proportioning of limestone and clay are making possible before the beginning of grinding. Generally, limestone is 80% and remaining 20% is the clay.

获取价格

Cement Plants located in India - The Global Cement Report

Cement plant locations and information on India can be found below. For full access to the database, purchase The Global Cement Report™, 15th Edition. Purchase. Summary. Cement capacity (Mt) Integrated plants. 172. Clinker plants. 4.

获取价格

KHD to install world’s first PYROROTOR

2017年12月22日 Combining KHD’s proven pyro-processing technology with its cutting-edge alternative fuel burning technology with, this project underlines KHD’s environmental technologies and leading market presence on innovative technologies in the cement industry for more than 160 years. Commissioning of the new system is scheduled for April

获取价格

Emission reduction through process integration and ... - Springer

2023年1月7日 Cement manufacturing includes grinding of the clinker with other additives like gypsum and fly ash. Clinker is manufactured by blending limestone, iron ore and bauxite at high temperatures, with limestone being the key ingredient. Hence, most of the clinker manufacturing plants or cement plants are located in the vicinity of limestone quarries.

获取价格

sbm/sbm ball grinding pyro.md at main changjiangsx/sbm

Contribute to changjiangsx/sbm development by creating an account on GitHub.

获取价格