crusher primary basalt

Crushed Basalt - Mobile Impact Crushers RUBBLE MASTER

Impact Crusher Can be Used as Primary or Secondary Crushers. RUBBLE MASTER mobile impact crushers can process basalt rock as a primary or secondary crusher

获取价格

When the Crusher Bucket is Transformed into a

5 之 In Egypt, a customer had accumulated a large amount of unused basalt in his quarry. However, storing these huge piles of material was costly, so he installed an MB Crusher BF120.4 jaw crusher on his

获取价格

MB Crusher: the innovative primary crusher that optimizes

2024年1月15日 The use of the mobile crusher eliminated the need for costly hauling services to move material between quarries. The use of the MB Crusher mobile jaw

获取价格

Influence of Basalt Aggregate Crushing Technology on Its

2023年1月8日 Characteristics of cracks in original samples: (a) Basalt aggregate 1, non-flaky grains, +8 mm; (b) Basalt aggregate 1, non-flaky grains, +16 mm; (c) Basalt

获取价格

Materials Free Full-Text Influence of Basalt Aggregate Crushing ...

2023年1月8日 Characteristics of cracks in samples after crushing in cone crusher (feed—non-flaky grains): (a) Basalt aggregate 2, non-flaky grains, +8 mm; (b) Basalt

获取价格

MASTER YOUR OUTPUT CRUSHER SELECTION QUICK GUIDE

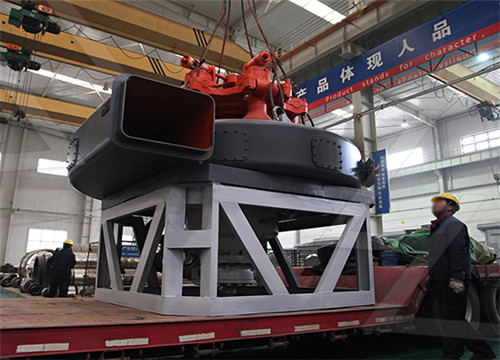

The first considerations are at what point in the process the crusher will be used, the type of material, and the output required. Use the table below as a guide. Primary Gyratory

获取价格

7 Mysteries of Basalt and How to Process Basalt Most Valuably

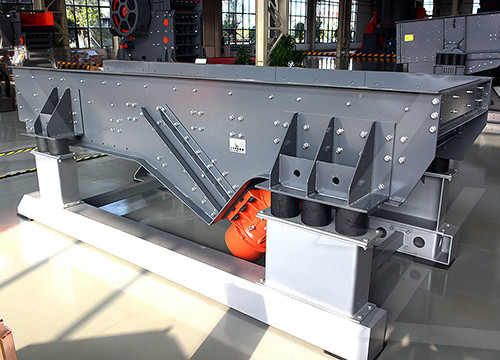

2023年4月10日 Basalt crushing process 1 Primary crushing: Basalt raw ore is evenly fed into the silo by the vibrating feeder and transported to the jaw crusher for coarse

获取价格

(PDF) Influence of Basalt Aggregate Crushing Technology on Its ...

2023年1月8日 Comparison of geometric indexes for analyzed basalt aggregates: (a) basalt 1; (b) basalt 2. Figure 7 shows the geometrical characteristic s of the basalt

获取价格

Basalt Crushing Sand Production Line - CM Mining Machinery

Design of Process of Basalt Sand Making Production Line. Crushing link: First, the raw basalt ore is evenly sent to the jaw crusher by the vibrating feeder for primary crushing,

获取价格

Materials Free Full-Text Influence of Basalt Aggregate Crushing ...

2023年1月8日 Figure 4 shows the results of the grain size distribution analysis for the primary samples of the tested aggregates. The basalt aggregates are characterized by similar grain sizes, except for the finest grain classes. ... Characteristics of cracks in samples after crushing in jaw crusher (feed—flaky grains): (a) Basalt aggregate 2, non-flaky ...

获取价格

Selecting the Right Crusher for Quarry Operations Agg-Net

2014年9月23日 These crushers offer an ideal solution for primary crushing applications involving hard, abrasive materials such as granite or recycled concrete. Efficient and less costly to operate because of their minimal moving parts, jaw crushers are well suited to applications where the primary objective is to reduce raw feed material to a manageable

获取价格

Primary and secondary raw materials

Required feed size for the cone crusher In selected example: UD: Slotted grate, AGW 2 1/2” LD: Wire cloth, CMS 22 mm; 7/8” Prescreen: Not required if primary screening of upstream jaw crusher is active. The No.4 content of fi nes produced by the jaw crusher are tolerated by the cone crusher. Jaw crusher: Adjustment of the jaw crusher, see

获取价格

Mengenal Mesin Stone Crusher Arparts

2021年1月17日 Primary crusher. Terdapat beberapa tipe crusher, yaitu: ... paling efektif digunakan untuk batuan sedimen hingga batuan yang paling keras seperti granit atau basalt. Keuntungannya antara lain kesederhanaan konstruksi, ekonomis dan memerlukan tenaga relatif kecil, ukuran material yang dapat dipecah tergantung pada feed opening

获取价格

What kind of crushing equipment is needed to produce cement

2023年2月16日 Cone Crushers: These are used to crush hard and abrasive materials like granite and basalt. They work by compressing the material between a stationary mantle and a rotating cone-shaped crushing head.

获取价格

African Mining News African Review Business Magazine

2024年1月24日 In India, another example has been provided by a client who was working with basalt. By installing a BF90.3 crusher bucket on a Komatsu PC200 excavator, the customer managed to obtain a final product of excellent quality. ... has outlined the key the benefits of selecting a crusher bucket as the primary crusher on quarries and the

获取价格

(PDF) Efficient Modeling and Control of Crushing ... - ResearchGate

2019年12月10日 Modeling and simulation is a tool to explore and increase the understanding of a phenomenon. This thesis focuses on developing models of crushers and equipment used in the mining industry ...

获取价格

Rock Crushing Rule of Thumb - 911 Metallurgist

2015年12月16日 Here is a list of Rules of Thumb often used in Rock Crushing and around Crushers: Crusher Selection. For a hard rock mine application below 600 tonnes/hour, select a jaw as the primary crusher. Over 1,000 tph, select a gyratory crusher. Between these capacities, you have a choice. Source: Chris Ottergren

获取价格

How to choose a basalt crusher - LinkedIn

2023年3月29日 Basalt crushers are widely used in the mining industry for crushing basalt rocks into smaller particles for further processing. ... Jaw crushers are ideal for primary crushing, while cone crushers ...

获取价格

NW130™ portable jaw crusher - Metso

The NW Series™ NW130™ portable jaw crusher is an electrically powered unit for the primary crushing and processing of basalt, granite, and other hard rock feed materials. The wheel-mounted chassis gives the unit high mobility between crushing sites. Efficient primary crushing for different applications

获取价格

Selecting the right type of crushing equipment - Quarry

2016年4月7日 A pit-portable primary crusher can be an economically sound solution in cases where the producer is crushing at the quarry face. In modern plants, it is cost-effective to use a mobile primary crusher, so it can follow the movement of the face where raw material is extracted. The most common use of track-mounted primary crushers is in ...

获取价格

Crushing Plant in The Philippines - AIMIX One-Stop Crush Solution

Stone material: hard stone – basalt; Feed material: 700mm; Discharge size: 0-1/4″-3/8″-3/4; Output: 200 T/H; Main configuration: one jaw crusher + two cone crushers + two vibrate screens; Reasons to Choose This Solution1. 1. The size of the basalt raw material is a little larger. Thus, it is better to use the jaw crusher for the primary ...

获取价格

What kind of crusher crushes basalt best? - LinkedIn

2023年3月21日 Jaw crushers are commonly used for primary crushing, and they are well suited for materials that are hard and abrasive, such as basalt. Cone crushers are also commonly used, especially for ...

获取价格

Basalt production without clamping device - Mineral Processing

Dump trucks transport the blasted basalt with unit sizes of up to 1000 mm from the quarry wall to the primary crusher plant. There, the material is removed from the bunker by means of a feeding device and reaches the jaw crusher via a primary classifying screen. The closed gap width of the C150 mostly ranges between 160 and 200 mm.

获取价格

Selecting the right type of crushing equipment

2016年4月7日 A pit-portable primary crusher can be an economically sound solution in cases where the producer is crushing at the quarry face. In modern plants, it is cost-effective to use a mobile primary crusher, so it

获取价格

Crushing Plant in The Philippines - AIMIX One-Stop Crush Solution

Stone material: hard stone – basalt; Feed material: 700mm; Discharge size: 0-1/4″-3/8″-3/4; Output: 200 T/H; Main configuration: one jaw crusher + two cone crushers + two vibrate screens; Reasons to Choose This Solution1. 1. The size of the basalt raw material is a little larger. Thus, it is better to use the jaw crusher for the primary ...

获取价格

What kind of crusher crushes basalt best? - LinkedIn

2023年3月21日 Jaw crushers are commonly used for primary crushing, and they are well suited for materials that are hard and abrasive, such as basalt. Cone crushers are also commonly used, especially for ...

获取价格

Basalt production without clamping device - Mineral Processing

Dump trucks transport the blasted basalt with unit sizes of up to 1000 mm from the quarry wall to the primary crusher plant. There, the material is removed from the bunker by means of a feeding device and reaches the jaw crusher via a primary classifying screen. The closed gap width of the C150 mostly ranges between 160 and 200 mm.

获取价格

Granite Crusher Machine - High Efficiency And Good In Shapes

Granite Jaw Type – Mainly for Primary Crushing Stage. Jaw crushers are generally used for primary crushing of granite. The wearing parts of AIMIX jaw granite crushing machine for sale are made of high-strength and high-toughness alloy wear-resistant material, which has less wear and long service life.The multi-stage continuous crushing chamber makes full

获取价格

What Kind Of Hammer Mill Stone Crusher Do You Need?

2023年4月12日 Factors influencing the choice of a crusher also include the required output size. If you need a fine powder, a hammer mill with a high speed rotor may be ideal. But if you need a coarser output, a lower rotor speed may be sufficient. The kind of material you’ll be crushing, its size and form, and the acceptable output size will determine the ...

获取价格

Basalt Crushing Plant Layout and Price - JXSC Machine

2019年10月12日 Basalt coarse crushing equipment recommended: jaw crusher (1-2200 t/h). The jaw crusher has a large feed port, deep crushing chamber, simple structure, convenient installation and operation, and is suitable for primary coarse crushing. Based on the basalt material properties, adopting laminating crusher can reduce wear.

获取价格

A Comprehensive Guide to Secondary Crusher Types - AGICO

2023年2月28日 Cone crushers are used in a variety of industries, including mining, quarrying, and recycling. In the mining industry, they are used to break down large rocks and minerals into smaller, more manageable sizes. In the quarrying industry, they are used to crush materials such as granite and basalt to produce aggregate for construction purposes.

获取价格

Mobile Rock Crushers - Performance. Simplicity. Safety.

Talk to an Expert. Since 1991, RUBBLE MASTER has brought numerous innovations to the market. We’re crushing screening experts and work closely with contractors and aggregate producers world-wide. RUBBLE MASTER's mobile rock crushers can process limestone, granite, shale, sandstone, basalt, and bluestone to produce high-quality aggregates.

获取价格

Basalt Processing Mastery: Crushing Lines and Crushers Unveiled

2024年1月11日 Basalt processing heavily relies on a series of crushing and screening equipment, categorized by their functions: 1. Jaw Crusher: Role: Primary crushing equipment, breaking large basalt chunks into smaller pieces through powerful squeezing.

获取价格

Uses of Different Types of Crusher - LinkedIn

2023年3月10日 Cone crushers are used to crush hard and medium-hard materials, such as limestone, granite, and basalt. They are widely used in the mining and quarrying industry.

获取价格

Environmental Efficiency Aspects of Basalt Fibers

2021年11月18日 basalt from sites and, consequently, crushed into the desired fraction (4–20 mm) by diesel-fueled mobile crushing machinery. This process consists of two subsequent crushing operations. First, the basalt rock is moved into the jaw crusher by a vibrating feeder to maintain primary crushing. Such preprocessed rock is fed to a cone

获取价格

CRUSHERS - mekaglobal

Our crushers have been designed to fullfill the various requirements of stone quarries, mining facilities and industrial. crushing groups—primary, secondary and tertiary—which are used to crush materials with dimensions up to 1000mm and vary depending on capacity, hardness and size of the material to be crushed.

获取价格

Keestrack B7 mobile tracked jaw crusher

Feed size up to 700 mm (28”), Vibrating feeder with 2step grizzly 2.200 mm x 1.080 mm (7'3" x 3'7"), Feed opening 1.200 x 830 mm (47” x 32,7”), C.S.S. min. - max. 75 - 140 mm (3" - 5.5”), Capacity up to 600 tonnes / hour, Full hybrid electric driven, energy saving version available, Removable feed hopper and feeder with scalper for transport, Intake hopper

获取价格