manufactured sand rock

Considering Manufactured Sand - Rock Products

2021年6月7日 The first step in the production of manufactured sand is crushing the rock to a gradation that when classified, by only removing the excess material passing the #100 and #200 sieve, will meet the C-33

获取价格

Research on the green preparation of manufactured sand by tuff

2023年12月15日 The influence of tuff-manufactured sand on concrete performance in Gansu region of China is studied. Tuff in Gansu Province, China, is a parent rock with

获取价格

Manufactured Sand Agg-Net

2008年6月2日 This led Kotobuki Engineering Manufacturing Co. Ltd (Kemco) to devise a process for the manufacture of consistent-specification sand, using crushed rock as a feedstock. The resulting system is known

获取价格

Considering Manufactured Sand - Rock Products

2021年6月7日 The first step in the production of manufactured sand is crushing the rock to a gradation that when classified, by only removing the excess material passing the #100 and #200 sieve, will meet the C-33

获取价格

A promising future for manufactured sand Aggregates Business

2017年11月9日 Reduced access to dwindling natural sand sites, coupled with higher quality sand products produced by crushing rock with premium crushing and screening equipment, has led to a flourishing manufactured sand sector within the quarrying and construction industries – a trend set to continue in the coming years. Below, building

获取价格

Manufactured Sand - दृष्टि आईएएस

2023年1月28日 The company is using crushed rock fines (crusher dust), sand from Overburden (OB) of coal mines. and soil removed during opencast coal mining, to produce Manufactured Sand (M-Sand). Avail 20-50% Discount on all Online, Pendrive Courses and Test Series from 21-25 January. Download Drishti Learning App.

获取价格

Granite Dust (M-10, Manufactured Sand) - Bulks Atlanta

Granite dust, as we call it is also known as M-10 or Manufactured Sand. Granite dust is highly-compatible and makes a great leveling base for patios and walkways. The coverage for this product is approximately 100 sq/ ft at a depth of 2” per ton. ... River Rock 4″-10″ ...

获取价格

M10 Sand for sale in Atlanta Granite Sand Granite Dust

M10 Sand is sand made from the process of crushing rock, usually granite. M10 sand is typically varies from light to dark gray in color. It can contain a mixture of coarse to fine grains of sand. It can be called manufactured sand, M sand, Man Sand, #10 sand, rock dust, granite dust, decomposed granite, or screenings.

获取价格

Influence of manufactured sand’s characteristics on its concrete ...

2018年5月30日 1. Introduction. Whereas the high-grade natural river sand (RS) gradually decreased in more and more areas in China, the market share of manufactured sand (MS) keeps sharp increasing for the boom of infrastructure construction [1], [2].Transported long distance by water or wind, RS is rounded and has characteristic abrasion patterns on its

获取价格

7 Types of Sand Used in Construction - BuilderSpace

2020年1月6日 But not all sand is the same as some have rocks and impurities that make them less resistant and stable for use in construction. The main types of sand used in construction range from concrete sand to pit sand, natural or river sand, manufactured sand (M-sand), utility sand, and fill sand. These types of sands have unique properties

获取价格

M Sand: Price, types and advantages for sustainable construction

2023年10月12日 The water absorption capacity of manufactured sand is 2% to 4%. As it is artificially produced, there are no oversized particles. There are lesser impurities in crushed sand compared to river sand. The bulk density is 1.75 gm per cubic cm. The specific gravity of manufactured sand is 2.5 to 2.9, depending on the parent rock.

获取价格

New insights into the contribution of quartz powder ... - Springer

2023年3月6日 Manufactured sand has been used as a green and economical alternative to natural aggregates in concrete due to resource shortage [].Inevitably, some particles finer than 75 μm with the same mineral composition as parent rock are produced in the production of manufactured sand [], which are normally called stone powder or stone

获取价格

Manufactured sand (MSand) washing plant - CDE Asia

CFlo's Solution for Manufactured Sand. Our manufactured sand washing systems efficiently deal with a number of issues for our customers including: Efficient removal of the minus 63 micron / 200 mesh material – typically 15%-20% of the feed. Crusher dust is typically very lean in the 63 micron to 600 micron / 200 mesh to 30 mesh range so it is ...

获取价格

What Is M Sand Properties of Manufactured Sand Advantages ...

2023年5月17日 M-Sand is artificial sand manufactured from crushing hard gravel into minor sand-sized angular molded units, wash away as well as excellently graded to be used as building aggregate.It is a greater substitute for River Sand for building purposes. Manufactured Sand (M-sand) is the utmost mutual alternative of river sand, which has

获取价格

Manufactured Sand - Hunter Quarries Barmac Cone

Barmac Manufactured Sand (BMS) is a natural sand alternative often utilised for asphalt and concrete purposes. A coarse sand, BMS is heavily utilised in the production of asphalt, with as much as 45% of each asphalt tonne made up of BMS. It is a product in high demand.

获取价格

Manufactured Sand for Construction - Structural Guide

2020年5月4日 Manufactured sand can be considered as a by-product of the process of producing coarse aggregates. When the rock is crushed into small particles, fine aggregates are produced. Due to the increasing demand in the construction sector, there is a difficulty in supplying the rever sand continuously to meet the demand.

获取价格

Performance evaluation of cement mortar produced with manufactured sand ...

2021年8月23日 Two manufactured sand types were considered in this study based on the sources used for production of manufactured sand: manufactured sands produced from Hornblende-Gneiss rock and Charnockite rock. Binder to sand ratios of 1:3, 1:4 and 1:6 were used reflecting the most common ratios considered for real engineering applications.

获取价格

What Is M Sand Properties of Manufactured Sand

2023年5月17日 M-Sand is artificial sand manufactured from crushing hard gravel into minor sand-sized angular molded units, wash away as well as excellently graded to be used as building aggregate.It is a greater

获取价格

Manufactured Sand - Hunter Quarries Barmac Cone

Barmac Manufactured Sand (BMS) is a natural sand alternative often utilised for asphalt and concrete purposes. A coarse sand, BMS is heavily utilised in the production of asphalt, with as much as 45% of each asphalt tonne made up of BMS.

获取价格

Manufactured Sand for Construction - Structural Guide

2020年5月4日 Manufactured sand can be considered as a by-product of the process of producing coarse aggregates. When the rock is crushed into small particles, fine aggregates are produced. Due to the increasing

获取价格

Performance evaluation of cement mortar produced with manufactured sand ...

2021年8月23日 Two manufactured sand types were considered in this study based on the sources used for production of manufactured sand: manufactured sands produced from Hornblende-Gneiss rock and Charnockite rock. Binder to sand ratios of 1:3, 1:4 and 1:6 were used reflecting the most common ratios considered for real engineering applications.

获取价格

Research on the green preparation of manufactured sand by tuff

2023年12月15日 The W bo and impact work index of the tuff were smaller than those of the traditional parent rock used for manufactured sand; therefore, the yield of tuff sand is larger under the same conditions; however, more stone powder is produced when it is broken. 2.4. Key technologies for the green preparation of tuff-manufactured sand2.4.1.

获取价格

An Investigation into the Use of Manufactured Sand as a 100% ...

2016年6月2日 One possible source of construction aggregate is sand that has been manufactured from the surplus material (crusher dust) that results when coarse aggregate is produced in hard rock quarries. Coarse aggregate production typically yields 25% to 45% crusher dust depending on the parent rock, crushing equipment and crushing conditions [

获取价格

Metamorphic rocks for manufactured sand and coarse aggregate

2022年8月12日 The present study determined the most applicable high-grade metamorphic rocks as the sources for manufactured sand and coarse aggregates production to apply in the construction industry. As the ...

获取价格

Riding Arena Sand Sand for Horse Arenas Premier Equestrian

Manufactured Sand. Rock quarries crush rock into sizes ranging from 5mm to fine dust. Mineral composition can range widely. They may be softer and break down to dust sooner. The fines and are sold as ‘manufactured sand,’ ‘man-made sand,’ ‘crusher fines,’ or ‘stone dust.’. These particles are sharp and will compact tightly if ...

获取价格

Detection of size of manufactured sand particles based on ... - PLOS

2018年12月14日 The size distribution of manufactured sand particles has a significant influence on the quality of concrete. To overcome the shortcomings of the traditional vibration-sieving method, a manufactured sand casting/dispersing system was developed, based on the characteristics of the sand particle contours (as determined by backlit

获取价格

Research on Compressive Strength of Manufactured Sand

2022年3月30日 Traditional natural river sand is used as a fine aggregate for concrete, but due to the severe environmental situation in recent years, many places have asked for a ban or restriction on the extraction of river sand. This has resulted in an increasing demand for concrete using machine-made sand instead of natural sand. The estimation and

获取价格

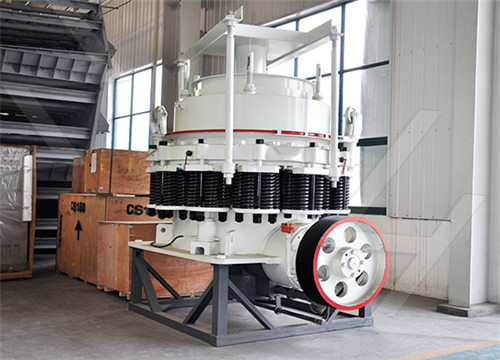

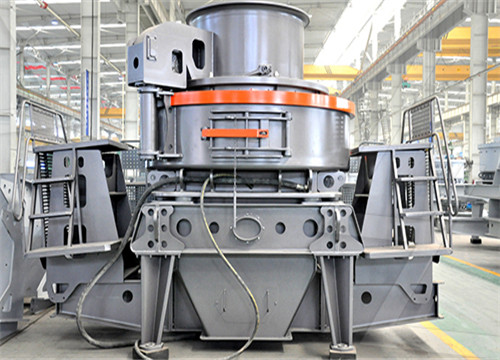

Everything You Need to Know About Sand Making Machine

2021年9月29日 Natural sand: Rock particles with a particle size of less than 5mm, formed by natural conditions (mainly weathering of rocks), are called natural sand. Manufactured sand:rock, mine tailings or industrial waste slag particles with particle size less than 4.7MM, which are made by mechanical crushing and screening after soil removal

获取价格

Aggregates Holcim US

Manufactured Sands . On a global scale, natural alluvial sand is becoming an increasingly depleted resource. Manufactured sands produced at hard rock quarries is a sustainable and versatile solution, offering high quality, fine aggregate that is

获取价格

6 Differences Between Manufactured Sand And Natural Sand

2021年10月27日 Natural sand: Rock particles with a particle size of less than 5mm, formed by natural conditions (mainly rock weathering), are called natural sand. Manufactured sand: Rocks, mine tailings or industrial waste particles with a particle size of less than 4.7mm, which are made by mechanical crushing and screening after soil removal

获取价格

Optimum Fines Content in Manufactured Sand for Best Overall

2023年10月31日 Due to a shortage of river sand for concrete production, manufactured sand (MS) made from crushed rock has gradually become a substitute. It inherently contains some fines content, which has significant effects on the performance of concrete. To study the effects of the MS type and fines content on the workability, cohesiveness,

获取价格