reduction ratio calculation jaw crusher

Crusher Reduction Ratio - 911 Metallurgist

2016年1月12日 Crusher Reduction Ratio. I have mentioned the fact that, as the % of voids in the crushing chamber decreases, the production of

获取价格

Jaw Crusher - ScienceDirect

2016年1月1日 The ore had to be crushed in a C-63 type jaw crusher 630 × 440. At a reduction ratio of 4, 18% of the ore was below the maximum size required. Determine: 1.

获取价格

Understanding the Reduction Ratio in Crushers

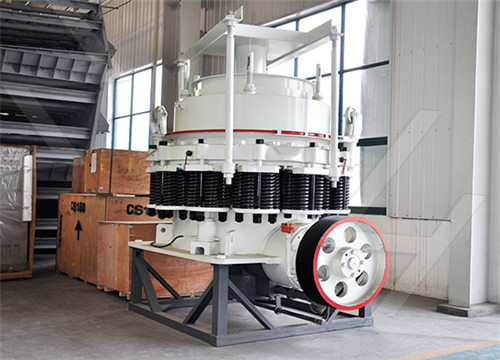

The right one for primary crushing often depends on the material to be crushed, but the reduction ratio of jaw crushers are usually between 8:1 and 6:1. Secondary Crusher. These crushers break down materials into

获取价格

Assessing the energy efficiency of a jaw crusher - ScienceDirect

2014年9月1日 For a jaw crusher the reduction ratio (R) is defined with gape (G) as: (A.1) R = G L min [−] Therefore the close opening set (L min) for a jaw crusher can be written

获取价格

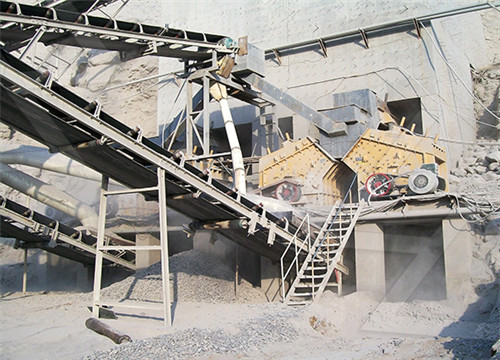

AMIT 135: Lesson 5 Crushing – Mining Mill Operator

The ratio of reduction through a primary crusher can be up to about 8:1. Feed: ROM up to 1.5 m; Product: -300mm (for transport) to -200mm (for SAG mill) Feed Rate: 160 to 13,000 tph; The family of primary crushers

获取价格

Jaw Crusher - an overview ScienceDirect Topics

ν= frequency (cycle/min) W = width of jaw plates (m) LMIN = closed set. R = machine reduction ratio (gape/set) and. QS = capacity (slow frequency) in terms of volume of

获取价格

TECHNICAL NOTES 5 CRUSHERS - Mineral Tech

Jaw crushers are operated to produce a size reduction ratio between 4:1 and 9:1. Gyratory crushers can produce size reduction ratios over a somewhat larger range of

获取价格

SANDVIK JAW CRUSHER SERIES - Sandvik Mining and Rock

Jaw crushers are normally capable of a reduction ratio of 1:2 or 1:3. This ratio is afected by the feed material’s bulk density, crushability, size distribution and moisture content –

获取价格

(PDF) SIZE REDUCTION BY CRUSHING METHODS

2017年3月4日 The paper deals with the problem of kinematic analysis of a planar six-joint mechanism of a jaw double-spring crusher. Computational techniques and software support have been used in the kinematic ...

获取价格

(PDF) SIZE REDUCTION BY CRUSHING METHODS

2017年3月4日 All crushers have a limited reduction ratio m eaning that size reduction will take place in stages. 3.2 Operation stages: The operating stages in minerals process ing have remained the same for ...

获取价格

(PDF) DESIGN AND OPERATIONS CHALLENGES OF A

2017年6月30日 RR i is the reduction ratio for ... The results show that an external diameter/offset ratio within the average of 10:1 can be considered for the offset calculation of a jaw-type crusher shaft. ...

获取价格

how to calculate jaw crusher reduction ratio- Crusher

Mar 28, 2021 It calculated by multiplying reduction ratios of all the stages (see formula below). R/R=R/R1*R/R2*.R/Rn n number of milling stages R/Rp reduction ratio of the p stage Source: formula.minerallurgy For example in a crushing circuit that consists of a jaw crusher (3/1), and a cone crusher ( 5/1), has a total reduction ratio of 15/1.

获取价格

Assessing the energy efficiency of a jaw crusher - ScienceDirect

2014年9月1日 For a jaw crusher the reduction ratio (R) is defined with gape (G) as: (A.1) R = G L min [−] Therefore the close opening set ( L min ) for a jaw crusher can be written as: (A.1) L min = G R [ m ] Rose and English [4] determine the size for which 80% of the feed passed, by considering a large data set relating the maximum particle size to the ...

获取价格

Reduction Ratio Calculator - ProGuide

2023年5月18日 Mathematically, the reduction ratio is calculated by dividing the size of the feed material by the size of the product. For example, if the feed material has a size of 100 millimeters (mm) and the product size after crushing is 20 mm, the reduction ratio would be 5:1 (100/20 = 5). This means that the crusher has reduced the size of the material ...

获取价格

McLanahan How To Size A Jaw Crusher

2023年6月23日 Jaw Crushers typically have a reduction ratio of 6:1, which means a 30” feed will be reduced down to 5” at the smallest size. The product size can be adjusted by opening or closing the gap between the jaw dies at the smallest point. ... They provide a 6:1 reduction ratio and can handle small and large tonnages. Jaw Crushers are a low-wear ...

获取价格

Roll Crusher - an overview ScienceDirect Topics

Jaw Crusher. This type of primary crusher is usually used for crushing shale to reduce it to a size suitable for handling. Roll Crusher. For a given reduction ratio, single-roll crushers are capable of reducing ROM material to a product with a top size in the range of 200–18 mm in a single pass, depending upon the top size of the feed coal ...

获取价格

How to Optimize Reduction Ratio in Jaw Crusher? - AGICO

2023年2月28日 The reduction ratio is a critical parameter for the performance of a jaw crusher. It affects the capacity, quality, and energy consumption of the machine. A high reduction ratio means a smaller product size and more fines. It also implies higher crushing force and energy consumption. On the other hand, a low reduction ratio means a larger ...

获取价格

Crusher Close Side Settings - 911 Metallurgist

2016年1月17日 The reduction ratio is driven by the Crusher Close Side Setting. The actual minimum safe closed side setting of a crusher will vary somewhat, for any given crushing machine, depending upon the character of the material, the amount of fines in the feed, and whether the crusher is being operated under choke-feed or regulated feed

获取价格

Experiment 02 Reduction Ratio of Jaw Crusher PDF - Scribd

The document describes an experiment to test a laboratory jaw crusher. It aims to: [1] study the parts of the jaw crusher and their functions; [2] analyze products using sieve analysis; and [3] calculate the reduction ratio. It provides details on the jaw crusher's construction, working principles, related terminology, and parameters like capacity and speed.

获取价格

Reduction ratio of Cone crusher,impact breaker,roll crusher,Jaw crusher ...

2012年12月31日 Uses impact to crush material. Reduction ratio is 20 to 1. Reduction ratio of Jaw crusher. A crusher that breaks material by squeezing or compressing it between two jaw plates, one moveable and one stationary. Normally used as a primary crusher. Uses compression and some attrition to crush material. Reduction ratio is 6 to

获取价格

What is a reduction ratio - Machinery Partner

Discounts available until March 31st or while stocks last! Browse Equipment. Equipment. For OEMs. Customers. About. +1 617 616 8454. Grow your crushing screening business with the right equipment, right finance, and expert support. Browse our range of excavators, screeners, crushers + more.

获取价格

What Is the Reduction Ratio of the Crusher? - vanguardtec

2022年3月11日 Surface reduction ratio: the ratio of the width of the crusher inlet to the width of the outlet. Calculation formula: I=0.85B/S (inlet width/discharge width referred to here) 0.85 is the width coefficient of the crusher to accommodate the material. The value S of the width of the discharge port: the coarse crusher is different from the medium ...

获取价格

Evaluation of size reduction process for rock aggregates in cone crusher

2020年6月4日 The crushability, grindability, and cutability of rocks are associated with many factors. During the size reduction processes in a jaw crusher and rod mill, crushing and grinding energy consumption increase when finer size fractions of the product are desired (Zeng and Forssberg 1992).Heikkilä (Heikkila 1991) reported that the lithological

获取价格

Reduction ratio of Cone crusher,impact breaker,roll crusher,Jaw crusher ...

2012年12月31日 Uses impact to crush material. Reduction ratio is 20 to 1. Reduction ratio of Jaw crusher. A crusher that breaks material by squeezing or compressing it between two jaw plates, one moveable and one stationary. Normally used as a primary crusher. Uses compression and some attrition to crush material. Reduction ratio is 6 to

获取价格

What is a reduction ratio - Machinery Partner

Discounts available until March 31st or while stocks last! Browse Equipment. Equipment. For OEMs. Customers. About. +1 617 616 8454. Grow your crushing screening business with the right equipment, right finance, and expert support. Browse our range of excavators, screeners, crushers + more.

获取价格

What Is the Reduction Ratio of the Crusher? - vanguardtec

2022年3月11日 Surface reduction ratio: the ratio of the width of the crusher inlet to the width of the outlet. Calculation formula: I=0.85B/S (inlet width/discharge width referred to here) 0.85 is the width coefficient of the crusher to accommodate the material. The value S of the width of the discharge port: the coarse crusher is different from the medium ...

获取价格

Evaluation of size reduction process for rock aggregates in cone crusher

2020年6月4日 The crushability, grindability, and cutability of rocks are associated with many factors. During the size reduction processes in a jaw crusher and rod mill, crushing and grinding energy consumption increase when finer size fractions of the product are desired (Zeng and Forssberg 1992).Heikkilä (Heikkila 1991) reported that the lithological

获取价格

Crushing in Mineral Processing - 911 Metallurgist

2015年12月26日 Primary crushers are designed so that the maximum size that can be presented to the crusher is approximately 80% of the gape. Jaw crushers are operated to produce a size reduction ratio between 4 :1 and 9 : 1. Gyratory crushers can produce size reduction ratios over a somewhat larger range of 3 :1 to 10 :1.

获取价格

EXPERIMENT:- Jaw Crusher

Jaw Crushers are made with jaw widths varying from about 150 mm to 1.0 mm and the running ... mass of material is constant for the same reduction ratio, that is the ratio of the Volume surface mean diameter before and after crushing. W = P/m=K k * In (Ds1/Ds2) Where, K₁ = Kick's constant

获取价格

What Is A Jaw Crusher - MEKA

MEKA Size Reduction Machines WHAT IS A JAW CRUSHER? / JAW CRUSHER. This is a type of crusher that is widely used in the primary and secondary crushing processes. ... Size reduction ratio. The ratio of the gape width to the near side jaw opening. This ratio may vary from 1/3 to 1/9, but is generally 1/3 for and 1/4 for secondary ...

获取价格

Selecting the Right Crushing Equipment Agg-Net

2015年10月28日 Jaw crushers Jaw crushers are often used as primary crushers and are perhaps the most popular crusher worldwide. They are suitable for almost any type of material. ... Double-roll crushers offer up to a 3:1 reduction ratio in some applications, depending on the characteristics of the material. Triple-roll crushers offer up to a 6:1

获取价格

Understanding Types of Jaw Crusher: A Comprehensive Guide

2024年2月6日 Blake jaw crushers, also as double toggle jaw crushers, are characterized by the position of the pivot of the swing jaw, which is located at the top of the machine. This design allows for a larger feed size and a higher capacity, making it suitable for primary crushing. The motion of the swing jaw in a Blake crusher is predominantly vertical ...

获取价格

Crusher Size Reduction Ratio Calculation Method Pages

Crusher size reduction ratio is the ratio of raw material particle size and particle size of crushing. 1. with the maximum size and the broken material after the product before the maximum particle size ratio calculation, Britain and the United States in the 80% materials through sieve aperture width is the maximum size diameter, China and the ...

获取价格

Crushing plant performance in achieving P80 grain size at PT

crusher and P80 cone crusher, calculate the reduction ratio, and determine the gold and silver per fraction. Based on the results of the Gaudin-Schuhmann P80 calculation, the average jaw crusher product is 66.3 mm and the average cone crusher product is 17.9 mm. While the reduction ratio of the jaw crusher is 1:13 and the reduction ratio of the ...

获取价格

Complete Lecture about Crushers in Cement Industry

A jaw angle of 15-20° results in a reduction ratio of 4 to 6. Various jaw crushers with different design features have been developed; of them generally two types remained master of the field, namely the double-tog gle jaw crusher (also called Blake-crusher), which is shown in Fig. 3.9. and the single-toggle jaw crusher shown in Fig. 3.10. [35].

获取价格

Gyratory Crusher - an overview ScienceDirect Topics

Generally, jaw and impact crushers exhibit a large reduction factor, defined as the ratio of the particle size of the input to that of the output material. A jaw crusher crushes only a small proportion of the original aggregate particles but an impact crusher crushes mortar and aggregate particles alike and thus generates a higher amount of ...

获取价格

View of Jaw crusher using in experiments. - ResearchGate

Sample amount was 150 kg for each test. A series of tests were made on the jaw crusher capacity of effective reduction ratios (2.5, 5, 10, and 20) and choke feed levels (1 = 1, 1 = 2, and 1 = 4 ...

获取价格