copper processing products

Copper Mining and Processing: Processing Copper Ores - Superfund

A. Processing of Oxide OreB. Processing of Sulfide OreC. Recycling CopperOxide ores are generally processed using hydrometallurgy. This process uses aqueous (water-based) solutions to extract and purify copper from copper oxide ores at ordinary temperatures, usually in three steps: heap leaching, solvent extraction, and electrowinning. Heap Leachingis the process of using percolatin在superfund.arizona上8

Copper processing Definition, History, Facts Britannica

Copper-processing technologies: Growing global

2023年2月17日 With demand for copper rapidly ramping up for the energy transition, new processing technologies can help overcome shortfalls in

获取价格

A Guide To Copper Production and Manufacturing

2022年12月23日 A Guide To Copper Production and Manufacturing Process. December 23, 2022 10:46 am. Copper is a sought-after metal for its durability, malleability, and conductivity. It has long been used in

获取价格

Copper processing - Ores, Refining, Smelting Britannica

The first step, mineral processing, is to liberate the copper minerals and remove waste constituents—such as alumina, limestone, pyrite, and silica—so that the copper minerals and other nonferrous minerals of

获取价格

Company Profile - Ningbo Jintian Copper (Group) Co., Ltd.

News from Ningbo Jintian Copper (Group) Co., Ltd. The company's copper processing products are rich in variety, and it is one of the few enterprises in China that can satisfy

获取价格

Copper Production: How Is Copper Made? - ThoughtCo

2019年9月26日 Copper processing is a complex process that involves many steps as the manufacturer processes the ore from its raw, mined state into a purified form for use in

获取价格

(PDF) Processing of Complex Materials in the Copper

2020年7月6日 PDF With the gradual decrease in the grade of copper ores being processed, copper concentrates have become more complex with higher impurity and... Find, read and cite all the research you ...

获取价格

Processing of Complex Materials in the Copper

2020年7月6日 Pyrometallurgical processing of complex copper concentrates has been traditionally associated with the smelting of specific materials containing substantial concentrations of deleterious elements,

获取价格

Copper Mining and Processing: Everything you Need to Know

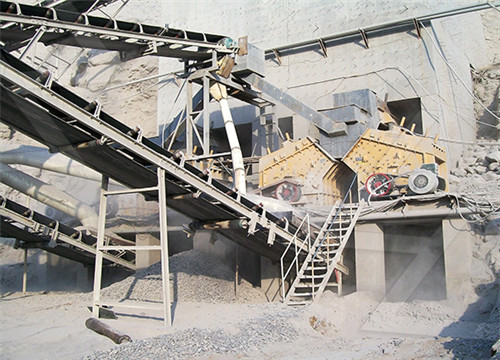

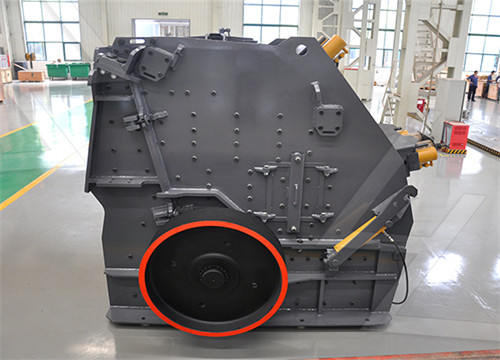

2014年7月17日 The Basics of Copper Mining and Processing. Mined from open pits, copper ore must be crushed as part of the process that occurs between extraction and production. Using today’s compact mining equipment, copper ore is extracted from the mine. After the ore is crushed, it’s roasted, which helps to convert sulfides to oxides.

获取价格

Copper processing - Roasting, Smelting, Converting

Copper processing - Roasting, Smelting, Converting: Once a concentrate has been produced containing copper and other metals of value (such as gold and silver), the next step is to remove impurity elements. In older

获取价格

Copper extraction - Wikipedia

By-products generated in the process are sulfur dioxide and slag. The sulfur dioxide is captured and converted to sulfuric acid and either sold on the open market or used in copper leaching processes. ... Copper Processing, from an online text on metals, Illinois Sustainable Technology Center, University of Illinois, archived in May 2017 ...

获取价格

Copper Processing Multotec

The cathodes are taken out of the tank and rinsed with water to prevent further reaction. The final copper cathodes can then be made into wires, plates, tubes, and other copper products. Did you know? Copper processing begins with mining copper ore, which contains less than 1% of copper, and ends with sheets of 99.99% pure copper (cathodes).

获取价格

Ames Copper Group - Shelby, NC

The AMES Copper Group process is considered a secondary copper refinery and consists of a pyrometallurgical process to transform scrap copper into copper anodes with over 99.7% pure copper. Secondary sources include scrap generated internally, new scrap from metal fabricators, and old scrap from consumer products. During our process, different ...

获取价格

Copper Smelting Process - Furnaces Used, By-Products, and Process

The ore is crushed, screened, and washed before being further processed ready to supply the smelting furnace. There are several methods of copper smelting, the popular ones being reverberatory smelting and oxygen flash smelting. Both methods require the resultant molten copper to be further processed to achieve a grade of 99.9% pure copper.

获取价格

Chinalco Luoyang Copper Processing-Leading manufacturers of

Chinalco Luoyang Copper Processing is one of the China's leading manufacturers of semi-finished and special products in copper and copper alloys with 70 years history.The company has focused on development and manufacturing of a full range of copper copper alloy materials, with an annual production capacity of 170,000 tons. The main

获取价格

The Life Cycle of Copper, its Co-Products and By-Products

R. U. Ayres et al The life cycle of copper, its co-products and byproducts vi Table 5.6: Energy consumption, emissions, wastes and byproducts from the production of 1 tonne of copper from secondary materials (a) , Germany 1992

获取价格

Copper Ore Processing Plants, Flow And Equipment

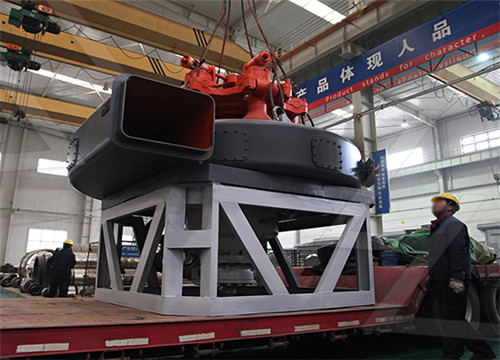

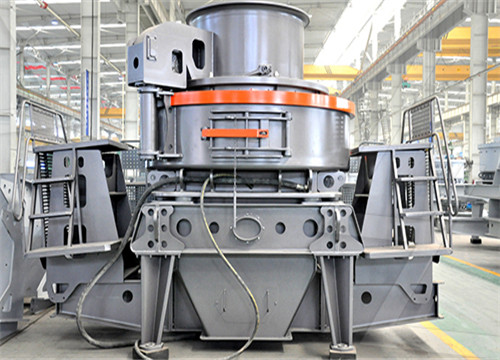

2024年2月29日 2. Grinding process. The copper ore processed into granules is screened by a vibrating sieve and sent to a ball mill for grinding and crushing. Here also need to use an auxiliary equipment – classifier. It can classify and screen copper ore and release copper ore powder that meets the requirements. 3.

获取价格

Copper Processing Equipment, Process Flow, Cases - JXSC

2019年8月23日 Copper ore processing. According to the metallurgy process, the copper ore is divided into three natural types by the ratio of copper oxide and copper sulfide. That is, sulfide ore, containing less than 10% copper oxide; oxidized ore, containing more than 30% copper oxide; mixed ore, containing 10% to 30% of copper oxide.

获取价格

Copper isotope ratios in Cis-Urals copper sandstones and products

2019年12月6日 Copper isotope ratios are determined by MC-ICP-MS in a number of Cis-Urals copper sandstones and products of their processing. Malachite crusts are characterized by positive δ 65 Cu (+1.33‰÷+1.96‰) whereas the sludge with flux additives and experimental glassy slag have the lowest negative δ 65 Cu values (-4.87‰÷-4.32‰).

获取价格

Processing of Complex Materials in the Copper Industry

2020年7月6日 With the gradual decrease in the grade of copper ores being processed, copper concentrates have become more complex with higher impurity and gangue content. This trend has had a detrimental effect on smelters as they have to increase throughput to maintain copper metal production, while increasing operating costs due to processing

获取价格

(PDF) Processing of Complex Materials in the Copper Industry ...

2020年7月6日 Seppon copper process ... Detrimental elements such as arsenic and antimony tend to accumulate in dusts and drosses of lead-zinc as well as copper smelters. These by-products are commonly treated ...

获取价格

The Impact And Development Trends Of CNC Copper Machined Products

2023年12月5日 The traditional manual processing method seems cumbersome in comparison. The introduction of CNC technology has made a qualitative leap in the quality and appearance of copper products. 2. Popularization Of Personalized Customization. CNC technology makes copper products easier to personalize, whether for home

获取价格

Copper isotope ratios in Cis-Urals copper sandstones and products

2019年12月6日 Copper isotope ratios are determined by MC-ICP-MS in a number of Cis-Urals copper sandstones and products of their processing. Malachite crusts are characterized by positive δ 65 Cu (+1.33‰÷+1.96‰) whereas the sludge with flux additives and experimental glassy slag have the lowest negative δ 65 Cu values (-4.87‰÷-4.32‰).

获取价格

Processing of Complex Materials in the Copper

2020年7月6日 With the gradual decrease in the grade of copper ores being processed, copper concentrates have become more complex with higher impurity and gangue content. This trend has had a detrimental

获取价格

(PDF) Processing of Complex Materials in the Copper

2020年7月6日 Seppon copper process ... Detrimental elements such as arsenic and antimony tend to accumulate in dusts and drosses of lead-zinc as well as copper smelters. These by-products are commonly treated ...

获取价格

The Impact And Development Trends Of CNC Copper Machined Products

2023年12月5日 The traditional manual processing method seems cumbersome in comparison. The introduction of CNC technology has made a qualitative leap in the quality and appearance of copper products. 2. Popularization Of Personalized Customization. CNC technology makes copper products easier to personalize, whether for home

获取价格

Top 10 Copper-producing Companies (Updated 2024) - Investing

2024年1月18日 Freeport-McMoRan believes that the deposit has the potential to produce more than 6 billion pounds of copper and 6 million ounces of gold between 2028 and the end of 2041. 2. Codelco. Production ...

获取价格

Copper Mining and Processing: Resources and Glossary

In copper processing, a copper cathode is the final, 99.99% pure product of the electrolysis process, and is itself the primary raw material input for the production of finished copper products, such as rode, tubes, and wires. cation: A positively-charged ion that is attracted to the cathode (negative terminal) in electrolysis.

获取价格

Review of copper pyrometallurgical practice: today and tomorrow

2003年10月1日 The paper outlines the global concepts for the hot metal processing of copper-bearing materials followed by traditional electrorefining to obtain saleable products. The copper industry is unlike the nickel or cobalt industries that are dominated by a few large producers (Mineral Commodities Summaries, 2003; Stirton and Brown, 1998).

获取价格

CRP Products - Cooper Plating

Cooper Rolled Products. With more than 20 high-performance precision copper alloys for rolled strip in our portfolio, we are able to supply the global copper processing industry with customized solutions.These include Boway’s self-developed copper-nickel-tin alloy, copper-nickel-phosphorus alloy, copper-nickel-silicon-cobalt alloy, copper-tin-phosphorus alloy,

获取价格

Copper processing - Smelting, Alloying, Refining Britannica

Copper processing - Smelting, Alloying, Refining: Because copper and nickel are completely miscible (i.e., they mix thoroughly) in the solid state, forming a complete series of solid solutions, the useful range of alloys is not confined within any definite limits of composition, although certain compositions have come into general use. Additions of 2 to

获取价格

Copper - Rio Tinto

Copper is essential to creating a sustainable, low-carbon world. Just one 1MW wind turbine, for example, uses 3 tonnes of copper. And electric vehicles use 4 times more copper than traditional vehicles. As a result, global demand for copper is set to grow 1.5%-2.5% per year, driven by electrification and increasing requirements for renewable ...

获取价格

Copper manufacturing process PPT - SlideShare

2022年1月22日 The copper ores undergo different processing depending on their chemistries Oxide Ore: Hydrometallurgy Heap Leaching Solvent Extraction Electrowinning Mining Transporting Primary Crushing Sulfide Ore: Pyrometallurgy Froth Floatation Thickening Smelting Electrolysis Final Product: 99.99% pure copper cathode. 11.

获取价格

Copper Mining and Processing: Summary and Learning Objectives

Module Summary. Copper is a chemical element that has a variety of uses based on its properties of malleability and conductivity. Copper ore deposits are found on every continent, and it has been mined around the world for more than 10,000 years. It is a necessary component for many products in the modern world. The steps involved in

获取价格

Copper - Wikipedia

Copper. face-centered cubic (fcc) ( cF4) Copper is a chemical element; it has symbol Cu (from Latin cuprum) and atomic number 29. It is a soft, malleable, and ductile metal with very high thermal and electrical conductivity. A freshly exposed surface of pure copper has a pinkish-orange color. Copper is used as a conductor of heat and ...

获取价格

Company Profile - Ningbo Jintian Copper (Group) Co., Ltd.

Ningbo Jintian Copper (Group) Co., Ltd., established in 1986, is a large-scale Chinese copper processing enterprise. The company's main business areas include copper processing, high-tech materials and building materials. Jintian Copper has more than twenty production and trade-oriented subsidiaries.

获取价格