limestone grinding ball mill

How does Limestone Grinding Machine Work and What ... - ball

A ball mill is a type of limestone grinding machine that uses steel balls to grind the limestone particles. The steel balls are rotated along with the limestone inside the drum

获取价格

Limestone Ball Mill - Limestone Grinder AGICO Limestone

What is a limestone ball mill? Limestone ball mill, also called a limestone grinder, is a kind of ball mill grinder, mainly used to grind lime ores. It is generally placed after the

获取价格

Ball Mill Particle Grinding - Union Process

The economical CL Attritor Stirred Vertical Ball Mill is used for wet grinding limestone for flue gas desulphurization. The process uses limestone feed stock of approximately 6mm

获取价格

Limestone Milling Process - Gravel Mill

What Type of Rock Is Limestone?Limestone Ball MillThe Working Process of Limestone MillProducts of Limestone MillUses of The Products of The Limestone MillA ball mill for limestone is a type of grinder used to grind materials into very fine powder for use in ceramics, paints, pyrotechnics, and mineral dressing processes. By revolving a cylinder filled with grinding balls, the ball mill grinds the material by causing the balls to fall back into the cylinder. Depending on the mill's diameter, the spinn...

A Technical and Economic Comparison of Ball Mill Limestone

2021年10月13日 The vertical roller mill (VRM) which has gained wide acceptance in the cement industry and is used for grinding raw materials (mainly limestone), is a

获取价格

5 Limestone Grinding Mills to Maximize Limestone Grinding

2023年3月24日 Ball Mill - Ball mills are widely used for grinding limestone in the cement industry. They are also used in other industries, such as power generation, metallurgy,

获取价格

What is Limestone Grinding Mill - SBM Mill Crusher

2023年5月15日 This mill, also known as the Raymond Roller Mill, is a common choice for limestone grinding. It works by rotating a grinding ring or roller around a fixed shaft, allowing the material to be ground by the

获取价格

Energy-Model and Life Cycle-Model for Grinding Processes of

2022年5月23日 search work was the examination of main grinding parameters of the limestone particles to determine an empiric energy-model. Dry and wet grinding

获取价格

Particle size distribution and structural changes in limestone

2014年1月10日 Abstract. The dry grinding of limestone in a planetary ball mill was investigated as a function of the diameter of the grinding balls and the revolution speed

获取价格

A Technical and Economic Comparison of Ball Mill Limestone

2021年10月13日 A pilot-scale Loesche VRM was used to determine the power required to grind 100 t/h of the same limestone as used at Kusile (work index of 12 kWh/t) with a top size of 19 mm to a 85% and 95% passing 45 µm product. A significant power saving of 39.2% was observed for the dry VRM compared to the wet ball mill (37.7% for the circuit).

获取价格

Planetary Ball Mills 101 - Union Process

Planetary Ball Mills 101 from Union Process Inc. Planetary ball mills share the same design as other basic ball mills – a grinding jar filled with media and rotated on its own axis. But their unique design takes advantage of centrifugal force and the Coriolis effect to grind materials to a very fine or even micron size. These forces come into ...

获取价格

Ball Mill - RETSCH - powerful grinding and homogenization

Ball mills are among the most variable and effective tools when it comes to size reduction of hard, brittle or fibrous materials. The variety of grinding modes, usable volumes and available grinding tool materials make ball mills the perfect match for a vast range of applications. Cooling, heating cryogenic grinding.

获取价格

Limestone Ball Mill - Limestone Grinding Mill

Limestone Ball mill can devide into 2 types, wet ball mill and dry ball mill. Ball mill is a mineral processing machine for milling the materials into powders after they are crushed. It is widely applied to the production of cements, silicate products, building materials, fireproof materials, fertilizers, glass, ceramics as well as nonferrous ...

获取价格

Selection Tips for Grinding Mills - Union Process

Compactability. Particle Shape. Dispersion Stability. Opacity. Flowability. Tap Density. Levels of Contamination. With its vast industry expertise, our staff can help you evaluate all the options and find the right grinding mills to ensure the most efficient effective operation for your business.

获取价格

Suitable FGD limestone mill, low investment in power plants

2023年2月15日 Grinding: grind the purchased limestone fragments with particle size less than 20mm in the wet-type limestone ball mill. Classification: pump the limestone slurry flowing out of the ball mill into the classification device to pick out the qualified limestone powder and recycle the coarse ones to the ball mill.

获取价格

Limestone Mill - High Efficiency, Large Capacity, 200-2500 Mesh.

The model selection scheme of limestone powder making main engine. Product specification (mesh) 95%particles’ grain size is over 200meshes. 90% particles’ grain size is over 250meshes. 90% particles’ grain size is over 325meshes, model selection scheme. Vertical mill or large scale Raymond mill. 1.Power consumption: 18~25kWh/ton, it ...

获取价格

Energy Use of Fine Grinding in Mineral Processing

2013年12月18日 Fine grinding, to P80 sizes as low as 7 μm, is becoming increasingly important as mines treat ores with smaller liberation sizes. This grinding is typically done using stirred mills such as the Isamill or Stirred Media Detritor. While fine grinding consumes less energy than primary grinding, it can still account for a substantial part of

获取价格

AMIT 135: Lesson 7 Ball Mills Circuits – Mining Mill Operator

Mill Type Overview. Three types of mill design are common. The Overflow Discharge mill is best suited for fine grinding to 75 – 106 microns.; The Diaphram or Grate Discharge mill keeps coarse particles within the mill for additional grinding and typically used for grinds to 150 – 250 microns.; The Center-Periphery Discharge mill has feed reporting from both

获取价格

Limestone mill, Limestone grinding mill - All industrial

centrifugal mill BGC. vertical stone for limestone. Final grain size: 250 µm - 800 µm. Rotational speed: 1,500 rpm - 6,000 rpm. Output: 650 kg/h - 13,000 kg/h. ... any type of dry of soft products with average hardness. THEORY OF OPERATION: - The product is loaded in the center of the mill by a feeding chute.

获取价格

Limestone Grinding Mill

Limestone grinding mill: —— five models: HGM80, HGM90, HGM100, HGM125and HGM1680L ——finished production fineness: 250meshes-2500meshes, 5-74 micron ——the capacity (ton/hour) ranges from 0.4T/H to 30T/H . ... mixing grinder and ball mill, and energy consumption decreased 30%.

获取价格

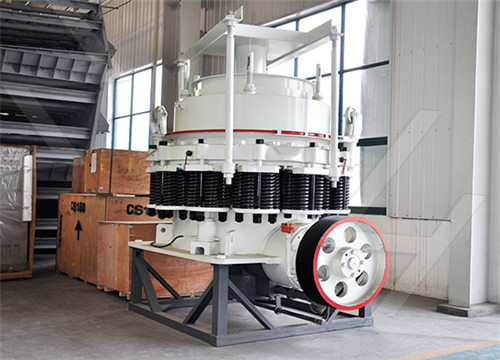

MQ Series Ball Mill - ZENITH Crusher

Ball Mill. Ball Mill is mainly used in metallurgy, chemical engineering, electricity, cement and other industrial and mining enterprises to grinding all kinds of ores and other grindable materials. It can grind limestone, calcite, marble, talcum, dolomite, bauxite, barite, petroleum coke, quartz, iron ore, phosphate rock, gypsum, graphite and ...

获取价格

High Energy Ball Milling - Stirred Ball Mill Stirred Media Mill

The savings in energy and the increase in grinding efficiency provided by Attritors are substantial. The graph below compares various mills during the high energy ball milling process. Select a link to learn more about these Attritor-style stirred ball mills: Dry Grinding – Continuous or Batch Mode. Dry Grinding – Continuous Mode

获取价格

A critical review on the mechanisms of chemical additives used in ...

2020年7月1日 In the grinding of limestone with polyacrylic acid as a GA, Zheng et al. [20] observed a drop in the mill power draw and improved ... Kokolev [64] studied the effect of organosilicon (0.005 wt. %) in the context of wet grinding of alumina in a ball mill where the grinding time decreased four-fold compared to grinding without any additive ...

获取价格

Limestone Grinding Mill

Limestone grinding mill: —— five models: HGM80, HGM90, HGM100, HGM125and HGM1680L ——finished production fineness: 250meshes-2500meshes, 5-74 micron ——the capacity (ton/hour) ranges from 0.4T/H to 30T/H . ... mixing grinder and ball mill, and energy consumption decreased 30%.

获取价格

MQ Series Ball Mill - ZENITH Crusher

Ball Mill. Ball Mill is mainly used in metallurgy, chemical engineering, electricity, cement and other industrial and mining enterprises to grinding all kinds of ores and other grindable materials. It can grind limestone,

获取价格

High Energy Ball Milling - Stirred Ball Mill Stirred

The savings in energy and the increase in grinding efficiency provided by Attritors are substantial. The graph below compares various mills during the high energy ball milling process. Select a link to learn more about these

获取价格

A critical review on the mechanisms of chemical additives used in ...

2020年7月1日 In the grinding of limestone with polyacrylic acid as a GA, Zheng et al. [20] observed a drop in the mill power draw and improved ... Kokolev [64] studied the effect of organosilicon (0.005 wt. %) in the context of wet grinding of alumina in a ball mill where the grinding time decreased four-fold compared to grinding without any additive ...

获取价格

Used Ball-mills For Sale - A.M. King

Buy used Ball-mills from A.M. King Industries. We can help guide you to the best solution for your equipment needs. ... [16] FILTERS [20] FLOTATION CELLS [19] GRINDING EQUIPMENT [82] HOISTS [12] LAB EQUIPMENT ... 2 Units - 12'6" x 24' FGD Limestone Ball Mills, 2000 HP (1491 kW) Manufacturer: MINERALS.

获取价格

Attrition Mills and Milling - Union Process

Wet Grinding Laboratory Mills Wet Batch Laboratory MillsWet Circulation Laboratory MillsChocolate Grinding Attrition MillsLimestone Slaker Ball Mill (CLS)Limestone Grinding Ball Mill (CL)Small Media Bead Mills (SDM) Wet Grinding Production Mills Wet Batch Production MillsWet Circulation Production MillsWet Continuous Production

获取价格

Closed and Open Circuits Ball Mill for Cement, Limestone, Iron ore

We bring forth a highly advanced Ball Mill, specifically engineered for both wet as well as dry cement grinding applications. Classified depending on the circuit design, bearing, grinding type and drive, the selection is made on the basis of the product fineness, quality, and nature of raw material, site conditions and specific requirements.

获取价格

Particle size distribution and structural changes in limestone ground ...

2014年1月10日 The dry grinding of limestone in a planetary ball mill was investigated as a function of the diameter of the grinding balls and the revolution speed of the mill. The tests were carried out with the same feed size (75 × 250 μm) at variable times up to 240 min.

获取价格

Factors That Can Impact the Limestone Grinding Process

A: Limestone grinding process involves feeding raw limestone (typically in the form of big boulders) into a grinding machine such as a Raymond mill or a ball mill. The machine grinds the limestone into a fine powder that can be used in various applications.

获取价格

Optimization of Ball Mill Grinding of a Limestone-Type

2023年4月13日 The effect of ball size and interstitial filling on the performance of dry ball mill grinding was investigated for a limestone-type brecciated uranium ore. The optimum grinding was obtained with ...

获取价格

Energy Saving Ball Mill, Limestone Grinding Ball Mill

Description of Ball Mill Ball Mill is an efficient tool for grinding many materials into fine powder. The ball mill is used to grind many kinds of mine and other materials, or to select the mine. It is widely used in building material, chemical industry, etc. such as cement, fire-proof materials, aluminum soil, the emery, glass raw materials, building sand, stone

获取价格

Energy-Model and Life Cycle-Model for Grinding Processes of Limestone

2022年4月17日 The grinding in stirred ball mill must be carried out with its own grindability measurement, and the appropriate factor is determined by determining the relationship between grinding fineness and specific grinding work. By stirred ball grinding of 20 min, the median particle size of the limestone products was 1.76 μm.

获取价格

Conventional Ball Mill vs. Attritors - Union Process

The savings in energy and the increase in grinding efficiency provided by Attritors are substantial. The graph below compares various mills during the high energy ball milling process. Select a link to learn more about these Attritor-style stirred ball mills: Dry Grinding – Continuous or Batch Mode. Dry Grinding – Continuous Mode

获取价格

Review on vertical roller mill in cement industry its performance ...

2021年1月1日 As per European cement research academy's project “Future grinding technologies”, out of 1036 orders of grinding mills in 5 years, 58% were for Vertical Roller mill and 40% were for Ball Mill + HPGR circuit. Hence Ball Mill VRM are major technologies in cement grinding. Their technological comparison is done beneath.

获取价格