iron ore beneficiation industry

Iron ore beneficiation: an overview - ScienceDirect

2023年1月1日 The beneficiation methodology includes processes that improve the physical, chemical, and metallurgical characteristics of iron ore concentrate that makes it desirable for iron-making processes. Such methods include size reduction or

获取价格

进一步探索

(PDF) Beneficiation and flowsheet development of a low (PDF) Flotation of Iron Ores: A Review - ResearchGateSeminar on iron ore beneficiation in india PPT - SlideShareBeneficiation of Iron Ores – IspatGuruCharacterization and Beneficiation of Dry Iron Ore ... - Springer

Introduction: Overview of the global iron ore industry

2022年1月1日 The iron ore industry is traditionally a carbon intensive industry and is now, more than ever, looking at ways of reducing its environmental impact. In 2020, Rio

获取价格

Driving investments in ore beneficiation and scrap upgrading

2021年5月20日 Cost analysis of iron losses due to an ore beneficiation and a scrap upgrade. The value of iron lost in an extra beneficiation operation is shown in Fig. 11 for

获取价格

Iron ore beneficiation: an overview - ScienceDirect

2023年1月1日 This chapter briefly discusses the current scenario of the iron ore resources in India, iron ore mining methodology, beneficiation technique, and the current

获取价格

Fine Size Dry Iron Ore Beneficiation Using Thin Bed Air

2 之 In the present study, iron ore feed with a size range of − 1 mm to + 0.1 mm with an assay of 58.28% Fe is subjected to dry processing on a thin/shallow bed air fluidized dry separator (TBAFDS). This unit is a

获取价格

Iron Ore Processing, General SpringerLink

2022年10月20日 “Beneficiation” of iron ore includes concentration, generally by physical removal of unwanted gangue; also, considered beneficiation is the regulation of product

获取价格

Beneficiation: Quality Starts with the Ore — Metals

2017年2月1日 Identifying the optimum ore-beneficiation procedures. Primetals Technologies has responded to the challenge of improving the quality of iron ore and has introduced a computer-based model that

获取价格

Iron ore beneficiation: an overview - ResearchGate

2023年1月1日 Download Citation On Jan 1, 2023, N.D. Rao and others published Iron ore beneficiation: an overview Find, read and cite all the research you need on

获取价格

World leader in fine iron ore beneficiation - Mineral

The world’s leading producers rely on us to deliver fine iron ore beneficiation solutions. With over 80 years' proven experience, we bring unrivalled expertise and the latest

获取价格

Key Points Downstream Beneficiation Case Study: Australia

Introduction. Australia was chosen as a downstream beneficiation case study because it has significant reserves of both coking coal and iron ore, as well as evidence of

获取价格

Dry beneficiation of iron ore - Mineral Processing

The haematite ore in South Africa is processed in a dry process to a HQ lump ore with 64 % iron content and a sintered fine ore with 63.5 % iron content. For fine ore beneficiation, wet processes are used. Capacity at the Minas Rio is to be increased from 26.5 Mta capacity to 28 Mta in the forthcoming years.

获取价格

Beneficiation - an overview ScienceDirect Topics

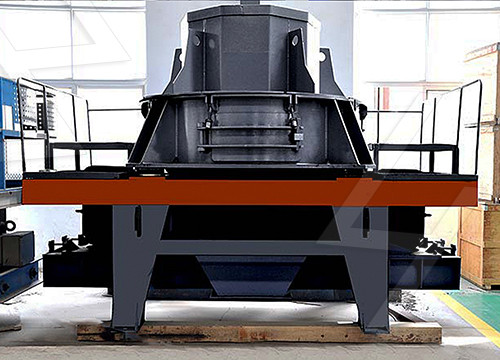

11.5.3.1 Beneficiation. Mineral beneficiation begins with crushing and grinding of mined ore for near-complete separation of ore and gangue minerals as well as between ore minerals. Each processing step is designed to increase the grade (concentration) of the valuable components of the original ore.

获取价格

The Chinese Iron Ore Deposits and Ore Production

2018年7月11日 Probably due to large national land area and multi-period orogeny, from the view of metallogeny, lots of iron deposits developed in China, and the proven total reserves of iron ores are relatively abundant,

获取价格

Iron Ore : Mineralogy, Processing and Environmental Sustainability

2021年12月2日 Iron Ore: Mineralogy, Processing and Environmental Sustainability, Second Edition covers all aspects surrounding the second most important commodity behind oil. As an essential input for the production of crude steel, iron ore feeds the world's largest trillion-dollar-a-year metal market and is the backbone of the global infrastructure. The

获取价格

KIOCL Ltd.

KIOCL Limited (Formerly known as Kudremukh Iron Ore Company Limited), a Flagship Company under the Ministry of Steel, Govt. of India was formed on 2 April 1976 for mining and beneficiation of low grade iron ore at Kudremukh, Karnataka, India.KIOCL has been a pioneer with over four decades of experience in operating Iron Ore Mining, Beneficiation

获取价格

Iron ore in Australia and the world: Resources, production ...

2022年1月1日 The most important iron ore resources are in Australia, Brazil, China, India, Russia, and Ukraine. As per the USGS, the world’s total economic reserves (“economically demonstrated resources (EDRs)” according to Geoscience Australia) are estimated at 170 billion tons (Gt) crude ore containing 81 Gt of iron (Table 22.1).Worldwide, iron ore is

获取价格

Key Points Downstream Beneficiation Case Study: Oman

steel casting and are used in conjunction with DRI pig iron production in integrated steel mills to maximize energy efficiency. The country has a growing iron ore-pelletizing sector, with Brazilian mining and metals giant Vale having commissioned its $1.35bn iron ore beneficiation plant in early 2012 with the objective of

获取价格

Chrome ore beneficiation challenges opportunities – A review

2011年4月1日 The beneficiation studies of Suresh et al. (1981), concludes that low grade chromite ore of 16–25% Cr 2 O 3, of Sitampundi area of India, cannot be upgraded by using tabling and flotation techniques, to meet the metallurgical grade due to the intimate association of iron in the lattice of chromite.

获取价格

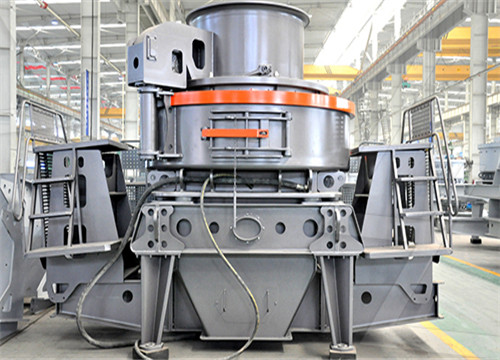

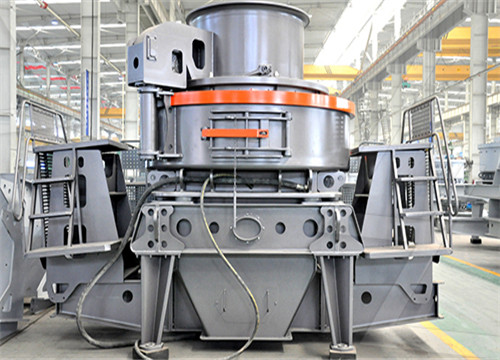

Iron Ore Industry – Beneficiation Technology

Iron Ore beneficiation Low grade iron ore bodies can be beneficiated using the DEC Flotation column and produce a saleable product at a low production cost per ton. Silica Removal Silica content has become a significant problem in iron ore processing in recent years. Lower grade deposits have significant silica content and this restricts the

获取价格

Indian Iron Ore Scenario : Low Grade Iron Ore Beneficiation

Indian Iron Ore Scenario : Low Grade Iron Ore Beneficiation Anand Kumar, Manager (mining), Omendra Singh, Design Engineer (Mining) MECON Limited, Ranchi - 834 002 ... quality specification of ore for iron making industry is summarized below: BF Lump Sinter Fines Pellet Fines Sponge Iron Feed Size Range (mm) -30+10/8 -10/8+0.15 -0.045 -18/16

获取价格

India's beneficiation of low-grade iron ore could result in new

2022年8月19日 An iron ore industry source in Singapore has doubts about India being a sustainable long-term supplier of high-grade iron ore. “There are costs involved in this. For example, new capital expenditure to set up beneficiation and concentration plants, so it’s not likely that every miner will be able to do it,” he said.

获取价格

Introduction: Overview of the global iron ore industry

2022年1月1日 Abstract. Iron ore is regarded as the second most important commodity behind oil. As an essential input for the production of crude steel, iron ore feeds the world’s largest trillion-dollar-a-year metal market and is the backbone of global infrastructure. To meet the growing demand for steel products, world iron ore production has increased ...

获取价格

Energy and Environmental Profile of the U.S. Mining

method of transportation is an iron ore slurry pipeline. 4.1.2 Iron Ore Beneficiation Iron ore occurs naturally in a variety of forms, from sand-like iron fines to solid rock masses. Crude ore, or ore mined in the natural state, seldom occurs in a pure state and requires some form of beneficiation. Crude ore is commonly mixed with other ...

获取价格

Beneficiation: Quality Starts with the Ore — Metals Magazine

2017年2月1日 By enhancing the quality of lower-grade raw materials through beneficiation, downstream processes also become more viable. Various production routes are available to transform iron ore into liquid steel, as shown in Figure 1. The selected route depends to a large extent on the quality of the iron ore, energy source and related costs.

获取价格

India's beneficiation of low-grade iron ore could result in new

2022年8月19日 An iron ore industry source in Singapore has doubts about India being a sustainable long-term supplier of high-grade iron ore. “There are costs involved in this. For example, new capital expenditure to set up beneficiation and concentration plants, so it’s not likely that every miner will be able to do it,” he said.

获取价格

Introduction: Overview of the global iron ore industry

2022年1月1日 Abstract. Iron ore is regarded as the second most important commodity behind oil. As an essential input for the production of crude steel, iron ore feeds the world’s largest trillion-dollar-a-year metal market and is the backbone of global infrastructure. To meet the growing demand for steel products, world iron ore production has increased ...

获取价格

Energy and Environmental Profile of the U.S. Mining

method of transportation is an iron ore slurry pipeline. 4.1.2 Iron Ore Beneficiation Iron ore occurs naturally in a variety of forms, from sand-like iron fines to solid rock masses. Crude ore, or ore mined in the natural state, seldom occurs in a pure state and requires some form of beneficiation. Crude ore is commonly mixed with other ...

获取价格

Beneficiation: Quality Starts with the Ore — Metals Magazine

2017年2月1日 By enhancing the quality of lower-grade raw materials through beneficiation, downstream processes also become more viable. Various production routes are available to transform iron ore into liquid steel, as shown in Figure 1. The selected route depends to a large extent on the quality of the iron ore, energy source and related costs.

获取价格

BENEFICIATION OF IRON ORE - National Institute of

Basic raw material for iron and steel industry is Iron ore which leads to our growing economy. India has huge reserves of quality iron ore which can fulfil the growing demand for domestic iron and steel industry as well as sustain large external trade. The most important iron ore types found in India are hematite and magnetite.

获取价格

Proposed beneficiation of low-grade iron ore evokes mixed

2022年8月25日 The government’s push for beneficiation of 80 per cent of low-grade iron ore has evoked mixed response with some miners saying the move will make iron ore mining an unviable business while ...

获取价格

(PDF) TECHNICAL AND ECONOMIC OVERVIEW OF IRON ORE

2016年1月1日 The Australian iron ore industry is export-orientated with around 85–90 %of production exported. In 2011, Australia continued to be the world’s largest exporter of iron ore, ahead of Brazil ...

获取价格

Reserves and Resources of Iron Ores of India — A Perspective

2022年5月12日 With a total resource of 22,487 million tonnes of haematite (Fe2O3) and 10,789 million tonnes of magnetite (Fe3O4), India ranks seventh among the countries to possess abundant iron ore resources, in the world. India is not only one of the leading producers of iron ore but also at present second largest manufacturer of steel in the

获取价格

Iron ore beneficiation: an overview - ResearchGate

2023年1月1日 The iron-making process requires high-quality raw materials, with Fe ≥ 64% and <2% alumina and silica each, to enhance blast furnace productivity at a given energy consumption rate. There is a ...

获取价格

Australia's iron ore industry faces a major challenge from its

1 Using one tonne of recycled steel for steelmaking saves 1.4 tonnes of iron ore and avoids about 1.5 tonnes of carbon dioxide emissions.. New tariffs on carbon. A number of legislative measures are on the horizon for the global steel industry, which produced about 7% of global greenhouse gas emissions in 2022.. One such international measure, the

获取价格

Ore Beneficiation - an overview ScienceDirect Topics

Microbially Induced Mineral Beneficiation. K.A. Natarajan, in Biotechnology of Metals, 2018 Biobeneficiation of Iron Ores. World demand for iron ores to meet the ever-increasing requirements of iron and steel industries has made it imperative to utilize all available resources including lean grade ores, mined wastes, processed tailings, and blue dust

获取价格

Iron Ore - 1st Edition Elsevier Shop

Iron Ore: Mineralogy, Processing and Environmental Issues . summarizes recent, key research on the characterization of iron ores, including important topics such as beneficiation (separation and refining), agglomeration (e.g., production of pellets or powders), blast furnace technology for smelting, and environmental issues relating to its

获取价格

IRON ORE BENEFICIATION Rashmi Group

Product : Sponge Iron. Rashmi Group is the largest manufacturer of Sponge Iron in Jhargram Kharagpur, West Bengal, India with a capacity of 3.19MTPA. We produce high-quality Sponge Iron that meets the industry standards. The production process followed at Rashmi Group makes the Sponge Iron unique and superior than its competitors.

获取价格

Beneficiation of Low Grade Iron Ore: Beneficial to whom?

2022年9月2日 The Union government had increased export duty on iron ore below 58 grade from zero to 50%. Miner’s Dilemma With frequent changes in policy taking place in the mining industry, Goa’s iron ore mining companies are unhappy over the notice of the Mines Ministry that recommends mandatory upgrading of ore through the process of

获取价格