safe work practices for gravel crusher

SAFE WORK PROCEDURE FOR Crushing Operations Screener

SAFE WORK PROCEDURE FOR Crusher/Screener Hazards Present: • Pinch Points • Falling • Wrenches slipping • Injury • Amputations • Rock falling • Working in a danger zone PPE or Devices Required: • Eye Protection • Hard Hat • Steel Toe Boots • Snug

获取价格

进一步探索

(PDF) Crushing and Screening Handbook - AcademiaSafety Operation Procedures of Crusher - Luoyang DahuaCrushing and Screening - Safety is our #1 PriorityCRUSHER - RISK HAZARD ASSESSMENT - Mobile Concrete Crusher SWMS SafetyDocs PDF Word

SAND, GRAVEL, AND CRUSHED STONE ON-THE-JOB

The following safe job procedures will help to minimize incidents which could cause injuries and adversely affect production. REQUIRED OR RECOMMENDED PERSONAL

获取价格

Site safety and safer aggregate crushing operations

2020年4月17日 Each company or site should have clear safety guidelines outlining best practices for the entire site, especially for crushers.

获取价格

Chapter 4: Safe Work Procedures - Wapiti Gravel

The purpose of this procedure is to provide personnel with safe working procedures when grading gravel surfaces. Scope The following procedures are to be used by all

获取价格

Site Safety and Safer Aggregate Crushing Operations

2019年9月11日 It is important to make sure that crusher operators follow all operational guidelines and that all safety best practices are in place, but also that the entire workforce is properly trained in site safety

获取价格

Top safety tips for working around crushing and

June 12, 2020. Working around crushing equipment can be hazardous; it's important for aggregates operations to keep safety in mind. Working around crushing and screening equipment brings plenty of potential dangers.

获取价格

Crushing Operation - yourACSA.ca

Safe Work Practice 0012. Ensure worker is competent to operate the crusher. Follow all manufacturer’s specifications and procedures for crushing operations. Inspect critical

获取价格

8 Tips for Crusher Safety Stewart-Amos Equipment

October 27, 2022. Crushing machines help reduce the size of rocks, concrete or construction rubble to safely dispose of debris or create material for production purposes. Every operator or employee who works with or

获取价格

SAND, GRAVEL, AND CRUSHED STONE ON-THE-JOB

RECOMMENDED SAFE JOB PROCEDURES 1. A) Wear life jacket. B) Use designated walkways, and examine for slipping/tripping hazards. C) Examine work area for

获取价格

SAND, GRAVEL, AND CRUSHED STONE ON-THE-JOB

safe job procedures for ground control. This module provides the miner with information on ground control, and hazards associated with highwalls, water pools, pits, spoil banks, and

获取价格

Top safety tips for working around crushing and

2020年6月12日 Employees should be equipped with fall protection in this process, Starck added. If the hammer doesn't work, a crane with a lifting strap or cable should be used. Never use steel bars, wedges or hooks to

获取价格

Caring for your cone crusher: A guide to optimising

2017年4月7日 Some inspections are best made after the crusher is shut down. An oil leak that developed during the day may still drip warm oil at that point. Tramp material from failed components may be freshly in evidence.

获取价格

Chapter 3: Safe Work Practices - Wapiti Gravel

Safe Work Practices Revision Date: June 1, 2017 Origination Date: Chapter 3 Page 3.9 Power Tools 3.4 Power Tools General Safety Rules Each power tool has its own unique safety hazards and these must be taken into consideration with each tool used. There are; however, general procedures that do apply to all power tools. The

获取价格

safe job procedures for gravel crushed - katastr-nahlizeni

Safe Job Procedures For Gravel Crushed Home Safe Job Procedures For Gravel Crushed PEW series Jaw crusher features big crushing ratio, reliable operation, easy 导航切换 Accueil

获取价格

HSE - Quarries - Safe operation and use of mobile jaw crushers

If the crusher is to be fed directly by a conveyor: All dangerous parts of machinery should be suitably guarded. Failure to replace guards (on crushers and conveyors) after cleaning or maintenance work is a major cause of injury on these machines. Fig. 2 Excavator feeding mobile stone crusher. Blocked crushers Causes

获取价格

Enhancing safety around crushers Pit Quarry

2018年2月16日 Additionally, keep your crusher working safely and efficiently by performing regular maintenance inspections. This allows you to pinpoint problems that may make the machine unsafe to use. Some tips to keep a safe crusher: Operate at the appropriate capacity. Keep platforms and areas around the machine clean.

获取价格

What Is A Gravel Crusher How Does It Work? - vykin

A gravel crusher is a piece of equipment used for crushing large rocks and gravel into smaller, more manageable pieces. This can be done for a variety of reasons, such as using gravel as construction material or for road maintenance. Gravel crushers are typically powered by gasoline or diesel engines and can also be electric-powered.

获取价格

Aggregates - IHSA

Aggregates refer to hard, granular materials such as sand, gravel, and crushed stone that are used for construction purposes. Anything made from concrete or asphalt requires aggregates. In Ontario today, almost every building, road, and structure contains some form of aggregate. Each year, the industry uses about 14 tonnes of aggregate for every person

获取价格

Introduction to Safe Work Practices AIChE

Safe work practices are a critical element in the management of industrial safety. For example, from 1992 to 2002, nitrogen asphyxiation during confined space entry resulted in 80 fatalities in the U.S. (Ref. 11.2). This rate of about 8 fatalities per year caused by exposure to a single inert gas is not significantly different from the rate of ...

获取价格

Safe and sound: Crusher safety Pit Quarry

2015年7月14日 Safe and sound: Crusher safety. A rock the size of a dining room table is plugged in the jaw crusher. After assessing the situation, a few people decide to wrap a chain around the rock and lift it out with a wheel loader. After securing the chain around the rock in the crushing chamber, a man still in the chamber tells the loader operator to ...

获取价格

SAND, GRAVEL, AND CRUSHED STONE ON-THE-JOB

RECOMMENDED SAFE JOB PROCEDURES 1. A) Wear life jacket. B) Use designated walkways, and examine for slipping/tripping hazards. C) Examine work area for exposed wires, frayed insulation, etc. D) Examine work area for missing guards, exposed moving machine parts, etc. Sound warning horn, if applicable. 2. A) Check that all moving parts

获取价格

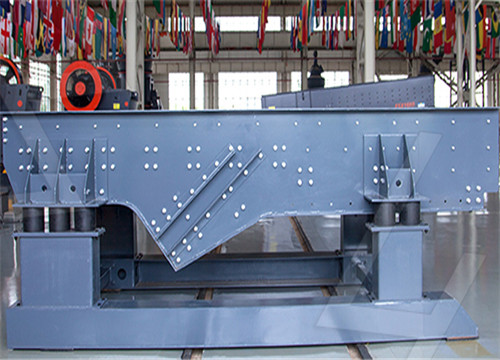

Gravel Crusher- An Overview of Its Operation and Application

What Equipment Was Equipped? APG-3896W vibrating feeder, APJ-5070E jaw crusher, APC-110C cone crusher and APS-1848Y vibrating screen. Advantages: APY4-6912S four-in-one mobile crusher is a multi-functional mobile crushing equipment with flexible movement, environmental protection and energy saving. Allows flexible movement

获取价格

Job Hazard Analysis - Rock Work - University of Montana

Quarrying, cutting, or splitting rock. Cuts or scrapes, from rock and freshly cut edges. -Freshly cut stone is extremely sharp, and workers need to exercise caution while handling or moving this material. -Clear work area often to reduce the chance of

获取价格

Safe Job Procedures Online Depository - Construction Safety

Crusher General Safety: Safe Job Procedures: Download: Crusher Lock Out: Safe Job Procedures: Download: ... Safe Job Procedures: Download: Gravel Checker: Safe Job Procedures: Download: Greasing a Vehicle: Safe Job Procedures: Download: ... Safe Work Practices: Download: Working Near High Voltage Power Lines: Safe Job Procedures:

获取价格

SAND, GRAVEL, AND CRUSHED STONE ON-THE-JOB

RECOMMENDED SAFE JOB PROCEDURES 1. A) Wear life jacket. B) Use designated walkways, and examine for slipping/tripping hazards. C) Examine work area for exposed wires, frayed insulation, etc. D) Examine work area for missing guards, exposed moving machine parts, etc. Sound warning horn, if applicable. 2. A) Check that all moving parts

获取价格

Gravel Crusher- An Overview of Its Operation and Application

What Equipment Was Equipped? APG-3896W vibrating feeder, APJ-5070E jaw crusher, APC-110C cone crusher and APS-1848Y vibrating screen. Advantages: APY4-6912S four-in-one mobile crusher is a multi-functional mobile crushing equipment with flexible movement, environmental protection and energy saving. Allows flexible movement

获取价格

Job Hazard Analysis - Rock Work - University of Montana

Quarrying, cutting, or splitting rock. Cuts or scrapes, from rock and freshly cut edges. -Freshly cut stone is extremely sharp, and workers need to exercise caution while handling or moving this material. -Clear work area often to reduce the chance of

获取价格

Safe Job Procedures Online Depository - Construction Safety

Crusher General Safety: Safe Job Procedures: Download: Crusher Lock Out: Safe Job Procedures: Download: ... Safe Job Procedures: Download: Gravel Checker: Safe Job Procedures: Download: Greasing a Vehicle: Safe Job Procedures: Download: ... Safe Work Practices: Download: Working Near High Voltage Power Lines: Safe Job Procedures:

获取价格

Everything You Need to Know About Gravel Crusher

Crushed gravel has diverse use cases, so you need to select the right gravel crusher for your construction needs. There are different types of gravel crushers available, such as impact crushers, cone crushers, and jaw crushers. So make sure to choose a rock crusher for gravel according to the type and scope of your project.

获取价格

Engineering Controls Database - Best Practices for Dust Control

Occupations typically exposed to silica dust from this source obviously include the crusher operators and truck drivers, and also the mechanics, cleanup men, and laborers whose tasks require them to work in this area. Description of control: Several methods for reducing worker exposure to silica dust at crusher locations are provided below:

获取价格

SAND, GRAVEL, AND CRUSHED STONE ON-THE-JOB

Under federal regulations, standards for the safe control of pit walls, including the overall sl ope of the pi t w all, must be establ ished and f ollowed by the o per ator . These standar ds shal l be consistent with prudent engineering design, the nature of the ground, and the type of material mined; and shall ensure safe working conditions.

获取价格

Mobile Concrete Crusher SWMS SafetyDocs PDF Word

Call us on 1300 306 604, send us a message via live chat or click the link below. 1300 306 604. Live Chat. Contact us. This Concrete Crusher (Mobile) Safe Work Method Statement (SWMS) covers hazards and controls associated with the operation of concrete crushers being loaded by an excavator.

获取价格

HSE BEST PRACTICES - SILICA PROTECTION - Alberta

HSE BEST PRACTICES - SILICA PROTECTION 1.0 Purpose 2.0 Training 3.0 Health Assessment 4.0 General Tasks 5.0 Sweeping floors/dust control 6.0 Maintenance of access roads 7.0 Crushing, Loading, Hauling and Dumping of Rock 8.0 Excavation/Tunneling Work 9.0 Interior Demolition 10.0 Exterior Demolition 11.0 Abrasive Blasting

获取价格

SAND, GRAVEL, AND CRUSHED STONE ON-THE-JOB

crusher. 6. Return to pit or quarry. 6. A) Collision with another vehicle. B) Run off road. RECOMMENDED SAFE JOB PROCEDURES D) Follow emergency safety procedures applicable to equipment and mine site. A) Stay on your side of road. B) Watch for other traffic. C) Back up slowly until rear tires reach stop block. 6. A) Stay on your side of the

获取价格

The Crusher Bike Challenge - Enhanced Gravel Adventure - 906AT

2023年12月31日 Who: Anyone signed up for the Crusher-EX and their support crews. What: 40, 100, or 225 miles of enhanced gravel. We even have a terrible 50-mile run and a ridiculous challenge called “The Fist”. When: July 1, 2024 – September 30, 2024. Where: Start and finish at Koski Korners, 13401 US Hwy 41, Champion, MI 49814.

获取价格

Safe Work Practices : BCCSA

Safe Work Practices. Safe Work Practices (SWP): Safe work practices are a set of methods or “Do’s and Don’ts” on how to carry out a specific task or use equipment. They should inform the worker about the hazards that are present and provide direction on how to safeguard against the hazards.

获取价格

Code of Practice for Pits - Open Government - Alberta

September 1, 2004. The Code of Practice for Pits applies to pits greater than five hectares (Class 1 pits) constructed on private land for removal of sand, gravel, clay, or marl. The Code addresses registration and operational requirements (Activities Plan, soil conservation, reclamation, reclamation security, reclamation certification ...

获取价格

ROCK CRUSHER SAFETY AND OPERATION - assets.ctfassets

2023年2月6日 Safety on a crusher starts with the employee-owner feeding the plant. The employee-owner feeding the plant needs to be trained on best practices specific to the crusher they are working with. An operator may have years of experience operating and loading a cone crusher, but that doesn’t translate into experience loading and operating

获取价格