iron ore concentrating mill

No. 7 Concentrating Mill - Abandoned

The six main steps of iron ore processing - Multotec

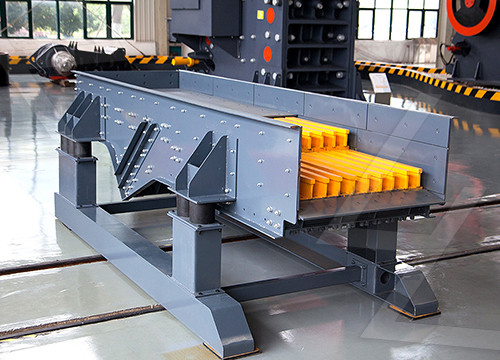

Screening. We recommend that you begin by screening the iron ore to separate fine

Iron Ore Processing, General SpringerLink

Gravity SeparationFlotationMagnetic SeparationMagnetic separation is a simple, yet effective method of iron ore beneficiation that exploit the difference in magnetic properties between the ore minerals in which magnetically susceptible materials are separated from a mixture using a magnetic force. Magnetic separation methods are mainly used to separate magnetic mineral such as magnetite, in so...

Comminution and classification technologies of iron ore

2022年1月1日 Iron ore is one of the main raw materials to make steel. About 98% of the mined iron ore is used to make steel either by the blast furnace—basic oxygen furnace

获取价格

Grinding iron ore concentrate by using HPGR and ball mills and

An iron ore concentrate sample was ground separately in a pilot-scale HPGR mill in multiple passes and a dry open-circuit ball mill to increase the specific surface area of

获取价格

Mechanism of magnetite iron ore concentrate morphology

2022年12月1日 Abstract. The effect and mechanism of magnetite concentrate morphology on the quality of indurated pellets were investigated. Concentrates with different

获取价格

Mining - Concentrator ArcelorMittal

For iron ore this involves crushing the ore and then concentrating it in different ways, for example by milling, flotation or magnetic separation. At some sites the ore is

获取价格

(PDF) The effects of iron ore concentrate grinding ... - ResearchGate

2020年10月18日 In this research, an iron ore concentrate sample was reground in a pilot HPGR and ball mill in order to study the effects of regrinding methods on the green pellet

获取价格

Grinding iron ore concentrate by using HPGR and ball mills and

2022年3月19日 Abstract. An iron ore concentrate sample was ground separately in a pilot-scale HPGR mill in multiple passes and a dry open-circuit ball mill to increase the

获取价格

Optimization of Solids Concentration in Iron Ore Ball

2019年6月18日 The present work analyzes comminution of a Brazilian iron ore with unusual breakage behavior in batch and pilot-scale tests, as well as in an industrial mill, which demonstrated the application of the scale

获取价格

Iron mining in the United States - Wikipedia

In 2014, the two mines produced 12.1 million tons of pelletized iron ore concentrate. In 2016 the Empire Mine was shut down. ... Because iron and steel-making at the time consumed more coal than iron ore, the steel mills moved closer to the coal mines to minimize transportation costs. Although later overshadowed by production from the Lake ...

获取价格

Iron ore - Wikipedia

The typical magnetite iron ore concentrate has less than 0.1% phosphorus, 3–7% silica and less than 3% aluminium. Currently magnetite iron ore is mined in Minnesota and Michigan in the United States, Eastern Canada and Northern Sweden.

获取价格

Mineral processing - Wikipedia

Crushing, a form of comminution, one of the unit operations of mineral processing. Mineral processing is the process of separating commercially valuable minerals from their ores in the field of extractive metallurgy.

获取价格

tilden - Michigan State University

Instead, the tumbling action of the ore in the rotating mills is sufficient to reduce it to a consistency of beach sand. Tilden has twelve primary mills that are 27 feet in diameter and 14 ½ feet long. Source: Photograph by Randy Schaetzl, Professor of Geography - Michigan State University ... Iron ore concentrate (known as "filter cake ...

获取价格

Iron Ore Concentration - Multotec

Mineral Spiral Concentrators. Our mineral spiral concentrators for separate iron ore mineral sizes from 1.5 to 0.04 mm. Available in three ranges, each of which reduces plant footprint by over 33%, their modular housing frames enclose two spiral assemblies, and their optional features can be fully dismantled for retrofitting purposes.

获取价格

Ore concentrate - Wikipedia

Ore concentrate. Ore concentrate, dressed ore or simply concentrate is the product generally produced by metal ore mines. The raw ore is usually ground finely in various comminution operations and gangue (waste) is removed, thus concentrating the metal component. [1] The concentrate is then transported to various physical or chemical

获取价格

Looking down the Fisher Hill mine shaft inside Republic Steel

Caption on photo reads: Looking down the fisher hill shaft. Inside the mines owned and operated by Witherbees, Sherman, Company until 1939; then, leased to and operated by Republic Steel until 1971. Circa 1940s. Mineville in the Town of Moriah, NY. Where: Mineville. When: 1940-1950.

获取价格

Titan In Berks - Berks History Center

Most of his biographers begin the “iron period” of his major inventions in magnetic ore concentration from this very year, 1891, when he closed the Bechtelsville mill. Interestingly, too, Edison did not sell his properties in Berks until 21 years later. Why did he hold the Berks County property even after the colossal Ogden project failed?

获取价格

The six main steps of iron ore processing - Multotec

3. Feeding the crusher (Reclaim) The surge pile allows a constant supply of material to be fed into the mill, which ensures consistent results and stability in the ore recovery process. 4. Grinding. The primary grinding mill grinds the material before it

获取价格

Common Basic Formulas for Mineral Processing Calculations

2016年3月20日 The control of a milling operation is a problem in imponderables: from the moment that the ore drops into the mill scoop the process becomes continuous, and continuity ceases only when the products finally come to rest at the concentrate bins and on the tailing dams. Material in process often cannot be weighed without a ...

Comminution and classification technologies of iron ore

2022年1月1日 The ROM ore is crushed using four in-pit gyratory crushers before being transported to the concentration plant. The crushed ore then enters a grinding circuit consisting of six grinding mill lines. Each line consists of a 12.2 m (40 ft) diameter × 11 m (36 ft) long AG mill with a 28 MW gearless motor in closed circuit with a pebble crusher and ...

获取价格

Addendum to Patrick F. Farrell Collection - ADKX Library:

2 // 9 // Iron Ore Concentrate – Representative Ore Samples Data from the Ore Structure on Different Mine Levels and Drill Sections, Showing Percentage of Magnesium, Iron and Phosphorus, 1970 ... Concentrating Mill No. 7 – Cross-Section Thru No. 7 Mill Showing Layout of Equipment. 716-1. // 45 x 61 cm // October 13, 1941 5 // Switchback ...

获取价格

Mills for minerals and ores Loesche

ORE MILLS. Successful inauguration of the New Steel Pilot Plant with a LOESCHE Ore Grinding Plant (OGPmobile) in Ouro Preto, MG, Brazil. Ouro Preto – The company New Steel has developed a revolutionary new process for iron ore concentration for which New Steel has been awarded with the internationally highly esteemed Platts Global Metals ...

获取价格

Magnetite Concentration Methods - 911 Metallurgist

2018年2月6日 At Benson Mines, New York, the Benson Iron Ore Co. is building a magnetic-separation mill with an estimated capacity of 3000 tons daily. Steam shovels are used to mine the ore, which is crushed in Edison giant rolls and separated on Ball-Norton separators. ... At Vintjarn, Sweden, a magnetic-concentration mill erected in 1906 is in

获取价格

Comminution and classification technologies of iron ore

2022年1月1日 The ROM ore is crushed using four in-pit gyratory crushers before being transported to the concentration plant. The crushed ore then enters a grinding circuit consisting of six grinding mill lines. Each line consists of a 12.2 m (40 ft) diameter × 11 m (36 ft) long AG mill with a 28 MW gearless motor in closed circuit with a pebble crusher and ...

获取价格

Addendum to Patrick F. Farrell Collection - ADKX Library:

2 // 9 // Iron Ore Concentrate – Representative Ore Samples Data from the Ore Structure on Different Mine Levels and Drill Sections, Showing Percentage of Magnesium, Iron and Phosphorus, 1970 ... Concentrating Mill No. 7 – Cross-Section Thru No. 7 Mill Showing Layout of Equipment. 716-1. // 45 x 61 cm // October 13, 1941 5 // Switchback ...

获取价格

Mills for minerals and ores Loesche

ORE MILLS. Successful inauguration of the New Steel Pilot Plant with a LOESCHE Ore Grinding Plant (OGPmobile) in Ouro Preto, MG, Brazil. Ouro Preto – The company New Steel has developed a revolutionary new

获取价格

Magnetite Concentration Methods - 911 Metallurgist

2018年2月6日 At Benson Mines, New York, the Benson Iron Ore Co. is building a magnetic-separation mill with an estimated capacity of 3000 tons daily. Steam shovels are used to mine the ore, which is crushed in Edison giant rolls and separated on Ball-Norton separators. ... At Vintjarn, Sweden, a magnetic-concentration mill erected in 1906 is in

获取价格

(PDF) Iron Ore Concentrate Particle Size Controlling Through ...

2018年10月8日 Iron ore concentrate wa s irradiated va rying the mi crowave expo sure time and gr inding effi ciency was evaluate d. The moisture infl uence in the HPGR ef ficiency was al so assessed.

获取价格

Optimization of Solids Concentration in Iron Ore Ball Milling

2019年6月18日 Important advances have been made in the last 60 years or so in the modeling of ball mills using mathematical formulas and models. One approach that has gained popularity is the population balance model, in particular, when coupled to the specific breakage rate function. The paper demonstrates the application of this methodology to

获取价格

Iron and steel industry in the United States - Wikipedia

Most iron and steel in the United States is now made from iron and steel scrap, rather than iron ore. The United States is also a major importer of iron and steel, as well as iron and steel products. Employment as of 2014 was 149,000 people employed in iron and steel mills, and 69,000 in foundries. The value of iron and steel produced in 2014 ...

获取价格

Energy and Environmental Profile of the U.S. Mining

Table 4-3 shows the estimated energy requirements for a surface iron mine in the U.S. The iron mine operates over a 22-year lifetime with a 110 million-ton output at the end of its life. The mine runs 364 days per year with two 8.00 hour shifts per day, which gives it a daily production rate of 13,699 tons per day.

获取价格

Winning the Metal: Ore Mills of the West - Western Mining History

The earliest, and simplest method of crushing ore was the use of arrastras. When enough capital was available, stamp mills replaced arrastras at most mines. The following sections take a look at various types of stamp mills, the most common milling facilities at mines of the frontier West. The Trench mill at Silver City, Nevada 1877.

获取价格

Iron Ore Agglomeration Technologies IntechOpen

2017年12月20日 Until the 1950s of the last century, the oxidized iron ores that were loaded into the blast furnace had granulometries within 10 and 120 mm. However, the depletion of high-grade iron ore sources has made necessary the utilization of concentration processes with the purpose of enriching the iron ore. Because of these processes, a fine

获取价格

Taconite Minnesota DNR

Taconite is a low-grade iron ore. When the high-grade natural iron ore was plentiful, taconite was considered a waste rock and not used. But as the supply of high-grade natural ore decreased, industry began to view taconite as a resource. Dr. E.W. Davis of the University of Minnesota, along with other scientists and engineers, conducted years ...

获取价格

A Robust Optimization Modeling for Mine Supply Chain Planning ... - Hindawi

2021年10月23日 The concentrating mill has a minimum ore grade for the raw ore, and the decision of the cut-off grades in multiple ore locations will be subject to the mining of the iron ore, as well as the corresponding processing, inventory, and transportation largely. ... It is the uncertainty available in the quality requirements of ore iron concentrates ...

获取价格

Grinding iron ore concentrate by using HPGR and ball mills and

2022年3月19日 An iron ore concentrate sample was ground separately in a pilot-scale HPGR mill in multiple passes and a dry open-circuit ball mill to increase the specific surface area of particles.

获取价格

Mining - Concentrator ArcelorMittal

For iron ore this involves crushing the ore and then concentrating it in different ways, for example by milling, flotation or magnetic separation. At some sites the ore is processed further and pelletised for use in direct reduced iron (DRI) steelmaking. In the processing stage, the mined material is transformed into usable raw material.

获取价格