What Is Ore Crushing And Screening In Korea

Ore, Rock Aggregate Screening (Complete Guide) - 911

The screening process: a vital component of the crushing circuit

2022年1月20日 The whole process philosophy is especially important when managing the crushing circuit, one of the biggest energy consumers in any plant. This is where

获取价格

CRUSHING SCREENING - Crushing and Screening

The screening process is just as important as the crushing itself. Screens are the heart of every rock processing plant. They are used to classify materials both in different stages of

获取价格

Ore Crushing SpringerLink

2023年7月22日 Ore coarse crushing is a process of crushing ore blocks with a feeding particle size of 500–1500 mm to 125–400 mm. The maximum crushing ratio of coarse

获取价格

(PDF) SIZE REDUCTION BY CRUSHING METHODS

2017年3月4日 Crushing of ore and minerals. There are three stages in crushing as stage 1, 2 and 3. ... Screening is generally limited to materials above about 250 microns in size, finer sizing normally being ...

获取价格

(PDF) ORE SEPARATION BY SCREENING - ResearchGate

2017年3月3日 Mechanical screening, often just called scr eening, is the practice of taking g ranulated ore material and separating it into multiple grades by par ticle size. This is called as size control.

获取价格

Comminution and classification technologies of iron ore

2022年1月1日 Iron ore crushing and screening. Iron ore is one of the main raw materials to make steel. About 98% of the mined iron ore is used to make steel either by the blast

获取价格

Crushing and Screening for Ore Sorting Success

Throughout this paper, we will explore the principles of ore sorting and how crushing and screening can impact ore sorting performance. Why use ore sorting? Ore sorting is one

获取价格

South Korea’s a premium aggregates producer

HAEIN managing director, Sung Wook Choi, says high-capacity stationary crushing and screening plant is most in demand among South Korea’s 500 to 600 aggregates

获取价格

Advances in screening technology in the mining sector

3 Screening machines for iron ore and coal. The crushing and screening systems for iron ore processing vary widely, depending on whether a magnetite or hematite deposit is being mined. While good quality magnetite is now dry-processed, hematite from deposits below the water line requires wet processing due to sticky quartz and clay contaminations.

获取价格

(PDF) SIZE REDUCTION BY CRUSHING METHODS

2017年3月4日 Crushing of ore and minerals. There are three stages in crushing as stage 1, 2 and 3. ... Screening is generally limited to materials above about 250 microns in size, finer sizing normally being ...

获取价格

What is Crushing and Screening Process? - Luoyang Dahua

2018年8月30日 The purpose of check-screening is to screen the crushed ore which are large than the discharge opening to ensure to get the qualified products. Luoyang Dahua can design the optimal crushing and screening process according to the customer condition, provide the high quality crusher machine. Through several decades

获取价格

Crushing Screening Plant - 911 Metallurgist

2016年7月12日 Methods used in Crushing Screening Plants on ore range from a simple combination of a grizzly and one crusher to an elaborate arrangement in series of grizzly, jaw crusher, screens, and rolls or cone crushers.. Crushing is done underground at a few large mines. In general, the jaw crusher is the most suitable primary machine, yet

获取价格

Screening 101 - 911 Metallurgist

2016年6月10日 Screening is the passing of material through definite and uniform apertures is the only true and accurate means of grading to a required particle size. Air separation and hydraulic classification depend upon gravity and particle shape, and result in the segregation and retention of material of higher specific gravity and lower surface area irrespective of

获取价格

Crushing and Screening Handbook - AusIMM

crushing. Stationary screens – an extensive range of complete screening solutions for scalping, closed circuit screening, fi nal sizing and de-watering. Single inclination, double, triple and horizontal models. Sand and gravel washing – to produce special quality rock materials for demanding construc-tion projects, such as bridges.

获取价格

Home - Auscrush

AusCrush and Recycle Pty Ltd is an Australian family-owned and operated company, specialising in mobile crushing and screening services. Our vision is to provide a sustainable solution to the quarrying and mining industry, by implementing our state of the art fuel efficient technology to provide crushing and screening services to our valued

获取价格

Comminution and classification technologies of iron ore

2022年1月1日 Some examples of different iron ore crushing and screening flowsheets are provided below: 8.2.3.1. ... Roy Hill is a joint venture between Ms Rinehart’s Hancock Prospecting and South Korean steel giant POSCO, Japanese company Marubeni and Taiwan’s China Steel Corporation. Designed to produce 55 Mtpa (wet) of lump and fines

获取价格

Crushing and Screening Agg-Net

2012年10月15日 Gyratory crushers – Gyratory crushers are used for hard and abrasive materials. Reduction ratios are typically 4:1 and maintenance is minimal. Gyratories represent a high investment cost but are typically long-life machines. They use approximately a quarter of a horsepower per ton per hour of material produced.

获取价格

Crushing in Mineral Processing - 911 Metallurgist

2015年12月26日 Crushing in Mineral Processing. In mineral processing or metallurgy, the first stage of comminution is crushing. Depending of the type of rock ( geometallurgy) to be crushed, there are 2 largely different techniques at your disposition for crushing rocks. In principle, compression crushing is used on hard and abrasive rocks by placing them ...

获取价格

Rock Processing - Home - SRP

Rock Processing Solutions. We are a trusted partner at the forefront of rock processing solutions for mining and infrastructure. Our commitment to innovation and customer profitability enables an offering spanning from crushing and screening to breaking, demolition, and service solutions. Join us as we pave the way for faster, greener, and ...

获取价格

Crushing in Mineral Processing - Eastman Rock Crusher

2020年4月20日 Crushing is the process of reducing the size of materials so that they can be further processed. In addition to being used in the chemical, coal industry, constrction area and so on area, industrial crushing equipment can be very useful in those variety of businesses. Also, crushin processing is widely used in waste and recycling, mining, food ...

获取价格

What is iron ore screening process? - LinkedIn

2023年4月21日 The screening process typically follows after the crushing and grinding of the iron ore. The purpose of iron ore screening is to separate the larger particles of iron ore from the smaller ones ...

获取价格

Rock Processing - Home - SRP

Rock Processing Solutions. We are a trusted partner at the forefront of rock processing solutions for mining and infrastructure. Our commitment to innovation and customer profitability enables an offering spanning from crushing and screening to breaking, demolition, and service solutions. Join us as we pave the way for faster, greener, and ...

获取价格

Crushing in Mineral Processing - Eastman Rock Crusher

2020年4月20日 Crushing is the process of reducing the size of materials so that they can be further processed. In addition to being used in the chemical, coal industry, constrction area and so on area, industrial

获取价格

What is iron ore screening process? - LinkedIn

2023年4月21日 The screening process typically follows after the crushing and grinding of the iron ore. The purpose of iron ore screening is to separate the larger particles of iron ore from the smaller ones ...

获取价格

What is the iron ore thickening process? - LinkedIn

2023年2月22日 The iron ore thickening process involves the steps of crushing and screening, grinding and classification, hydrocyclone separation and desliming, flocculation, sedimentation, filtration ...

获取价格

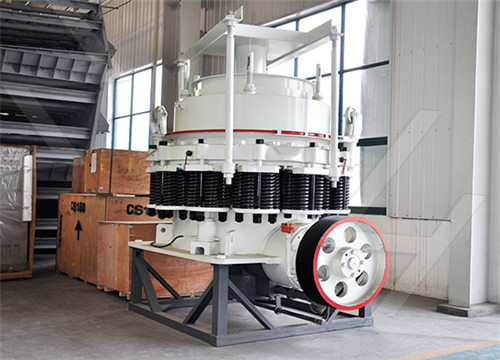

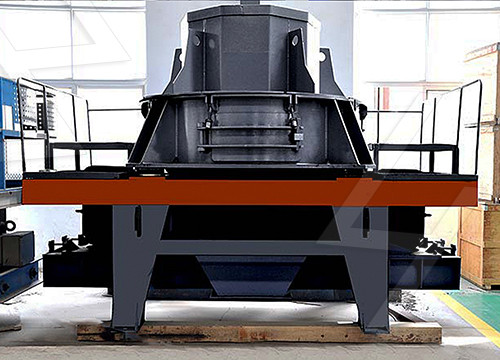

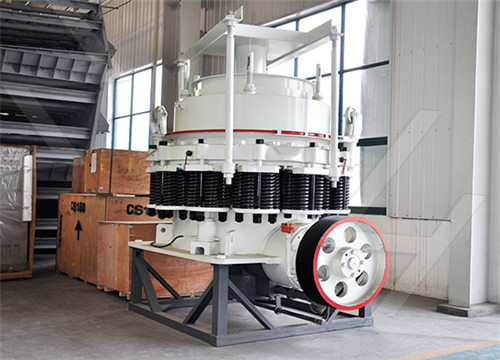

Ore Crushing and Screening Plant, Mineral Crushing Plant

Ore crushing and screening process. In order to achieve the ideal size, the ore crushing generally undergoes three stages: primary crushing, secondary crushing and fine crushing. In general, the PE jaw crusher is used as the primary crusher, this is because it has the characteristics of high processing capacity and stable operation. ...

获取价格

What is mineral dressing or ore beneficiation? - LinkedIn

2019年12月12日 In primary crushing, ore or run-of-mine ore (up to 1 m in size) is crushed down to about 10 cm and it is done in a jaw or gyratory crusher. – ii. Secondary Crushing (intermediate crushing):

获取价格

Iron Ore Company of Australia selects Crushing for

2023年8月30日 The selection of Crushing for crushing services reinforces the assumptions made within the scoping study to deliver a C1 cost of approximately $60 per tonne, Alien Metals says. The 2021 scoping study on Hancock showcased a 1.25 Mt/y production profile that would sustain an eight-year life of mine with current resources.

获取价格

Measurement-Control for Crushing and Screening Process

2023年6月3日 It mainly includes crushing process control, crushing appliance fault diagnosis, and automatic distributing control. Crushing Process Control. To ensure the continuous, stable, and safe operation of the ore crushing production process, it is necessary to monitor the running state and parameters of key equipment (such as

获取价格

Equipment for crushing, screening more - Power Screening

Power Screening is an authorized dealer for ’s full line of crushing, screening and conveying equipment. We provide full service sales, rental, parts and service support at our Henderson, Colorado and Albuquerque, New Mexico locations. machines cover the full range of material processing requirements with mining ...

获取价格

What is the process of mining iron ore? - LinkedIn

2023年3月30日 The process of mining iron ore involves drilling, blasting, hauling, crushing and screening. First, holes are drilled into the rock surface using large machines. Then, explosives are inserted into ...

获取价格

Crushing Screening Contractors – Crushing

MACKAY: (07) 4952 3888. Crushing Screening Contractors. We’re not your average crushing screening operator! We do things differently to achieve greater mine-site efficiency and cost savings to the mine site operator. Crushing provides the plant, equipment and personnel to crush and screen ore or quarry material, usually at a rate ...

获取价格

Mobile Crushing Screening - Astec

Astec offers a broad range of mobile crushing and screening plants, including mobile cone, jaw and impactor plants, as well as a variety of mobile screening and conveying plants. Designed for jobs that require quick and easy site mobility, our mobile product lines give producers flexibility without sacrificing productivity.

获取价格

what is iron ore screening equipment? - LinkedIn

2023年2月10日 The screening process is an essential part of the iron ore production process and it helps to separate the iron ore into different grades and sizes, which are then used in various applications ...

获取价格