ore beneficiation mercury

Investigation of Gold Recovery and Mercury Losses in Whole Ore

2023年7月26日 Initially, the amount of mercury added by the miners for ore beneficiation in Chilean mills (test 1) was taken as a base; in the same way, it was tested to replicate three grinding cycles (tests 2, 3, and 4), reducing the mercury addition by 20%.

获取价格

进一步探索

(PDF) Investigation of Gold Recovery and Mercury Losses in (PDF) Estimation of Mercury Losses and Gold Production Mercury Amalgamation and Fine Gold Recovery - Gold losses and mercury recovery in artisanal gold mining on Mercury in Gold Processing - ScienceDirect

The Mercury Problem in Artisanal and Small-Scale Gold

2018年1月3日 Liquid mercury is used in artisanal and small-scale gold mining. a) Trommels are used to crush rock and mix mercury with ore.

获取价格

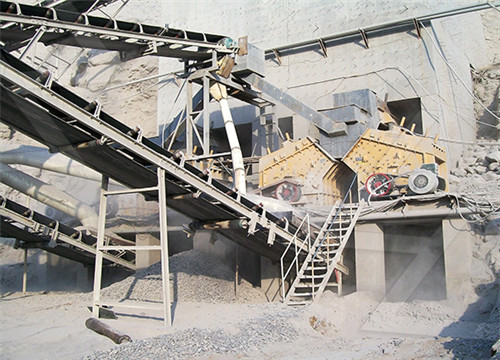

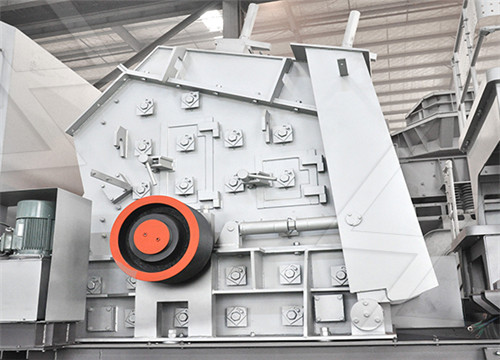

Mercury Ore Processing - 911 Metallurgist

A Mercury Ore Beneficiation Process FlowsheetFlotation of MercuryThe Mercury Ore Beneficiation by FlotationCrushing CircuitConventional single stage crushing comprises this section, since the tonnage is less than 100 tons per day. The mine ore is fed from the coarse bin by means of a Apron Feeder to the Jaw Crusher. Crusher feed passes over a grizzly with an opening similar to the crusher setting. Grizzly undersiMercury Ore Grinding SectionThe Mineral Jig and Unit Cell are installed in the ball mill-classifier circuit to recover an important amount of the freed cinnabar at a relatively coarse particle size, desirable because of cinnabar’s tendency to be friable and slime easily. In addition, the coarser concentrates are preferred for ret在911metallurgist上9

An Examination and a Solution to replace the use of

March 23, 2023. Times viewed. Share on. The use of mercury in artisanal ore processing causes damage to the nervous system, digestive system, immune system, lungs, thyroid, and kidneys; causing

获取价格

An Examination and a Solution to replace the use of Mercury in ...

2022年8月26日 Abstract. A scalable ESG-driven climate action initiative to replace artisanal gold ore processors use of mercury, a deadly neurotoxin, with manipueira,

获取价格

Guide to Mercury Ore: How to Benefication? - JXSC

2022年9月20日 The mercury process plant is a production line for the beneficiation and purification of mercury ore. However, the beneficiation methods and processes are also different according to

获取价格

GOLD RECOVERY BY MERCURY AMALGAMATION

The beneficiation carried out using centrifugal separation, regarded as an extension of gravity separation, showed gold grades in the range of 535–1515 g t−1 for gold ores and 36–302 g t−1 ...

获取价格

Reducing Mercury Impacts in Small-Scale Gold Mining - UNEP

The savings in mercury point to the huge benefits that could be achieved by making such technologies an integral part of the small-scale mining process across Indonesia and the

获取价格

Mercury and artisanal and small-scale gold mining: Review of

2023年3月10日 The process entails combining mercury with gold-bearing ore or concentrate. A gold-mercury amalgam is formed, which is heated to vaporize mercury,

获取价格

Beneficiation of Gold and Silver Ores SpringerLink

2019年12月15日 Ore sorting. Dense media separation (DMS) Coarse particle flotation. Magnetic separation. Electrostatic separation. Download chapter PDF. This chapter

获取价格

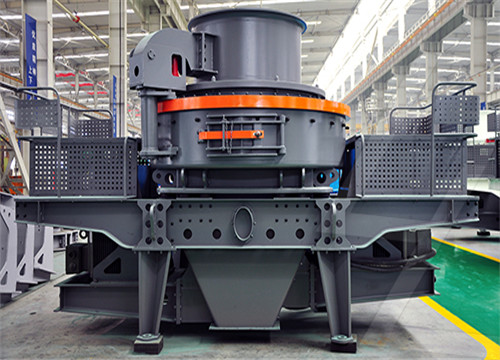

Cinnabar Beneficiation Equipment, Mercury Ore Beneficiation

2021年5月20日 The above picture shows three different types of mercury ore. Among them, the beneficiation of massive mercury ore and speckled mercury ore is very simple, and good beneficiation indicators can be obtained through manual and gravity beneficiation. Because in the disseminated mercury ore, the mercury minerals and the

获取价格

A systematic review of sustainable gold extraction from raw

2022年3月1日 In general terms, ore sorting is the process, ... The gravity concentration process, which exploits differences in mineral densities, is the oldest known beneficiation method; it is a cheap and environmentally friendly process. ... Gold-containing Mercury/Antimony: A xanthate collector with cyclic alcohol frother (e.g. pine oil) together

获取价格

GOLD RECOVERY BY MERCURY AMALGAMATION

The beneficiation carried out using centrifugal separation, regarded as an extension of gravity separation, showed gold grades in the range of 535–1515 g t−1 for gold ores and 36–302 g t−1 ...

获取价格

Beneficiation of antimony oxide ore: A review - Springer

2017年9月7日 Antimony oxide ore beneficiation has become one of the world’s largest mineral processing conundrums. In recent years, many experimental studies dealing with antimony oxide ore have been carried out, resulting in new technical achievements. Much attention has been paid to improving the mineral processing technology of antimony oxide

获取价格

Existing and New Processes for Beneficiation of Indian Iron

2020年2月8日 The iron ore industries of India are expected to bring new technologies to cater to the need of the tremendous increase in demand for quality ores for steel making. With the high-grade ores depleting very fast, the focus is on the beneficiation of low-grade resources. However, most of these ores do not respond well to the conventional

获取价格

Guidance for Short-Term Storage of Elemental Mercury by

producing elemental mercury waste from the beneficiation or processing of ore or related pollution control activities (i.e., Ore Processors). Such storage, which is contingent on specific requirements, is provided for in the Chemical Safety Act of

获取价格

Beneficiation of Gold and Silver Ores SpringerLink

2019年12月15日 The importance of ore sorting in improving economics of marginal deposits is increasing, being realized by the mining industry (Lessard et al. 2014; Foggiatto et al. 2014). At present, majority of automated ore sorters , outside of the diamond industry, are color or conductivity sorters (Bartram and Kowalczyk 2009). This is a significant ...

获取价格

Gold Round Mill/Wet Pan Mill / Wet Pan Mill - Henan Forui

The beneficiation method and process of the wet pan mill in gold ore dressing: 1. After installation and debugging, add about 5 kg of mercury to the bottom of the tank of the wet pan mill and start to work normally. 2. Collect the gold dust once for each shift. Add 1 kg of mercury in the shift to collect the ground bottom of the gold dust and ...

获取价格

DO YOU KNOW HOW TO IMPROVE THE GRADE OF MERCURY ORE

2021年8月23日 The most commonly used gravity beneficiation equipment for mercury ore are shaking tables and jig concentrators. The shaker can obtain high-quality concentrate for the production of cinnabar products. The jigging machine is mostly used before grinding or in the grinding and classification circuit to recover the dissociated cinnabar in time to ...

获取价格

What is the Beneficiation Process? - AZoMining

Oct 1 2014. The beneficiation process can be defined as a treatment process of ore which results in a more concentrated form of the product. It is often used in the preparation of iron ore for smelting. This is an essential process as it helps improve the yield from a deposit of ore, thereby increasing the potential profits that can be obtained ...

获取价格

Valorization From Waste: Combined Reduction of Chromite Ore

2024年1月10日 Chromite ore processing tailings and low-grade manganese ores are typically considered waste due to their limited or negligible utility, leading to environmental and storage concerns. ... which brings challenges to the selection and identification of suitable beneficiation processes for the ore ... (vi) and mercury (ii) – implications in ...

获取价格

Ore Beneficiation - an overview ScienceDirect Topics

Iron ore beneficiation can be brought about through three approaches, namely, selective dissolution, microbially induced flotation, and selective flocculation–dispersion. The bioprocesses are specially suited to treat fines, slimes, and waste tailings. 4. Potential applications include.

获取价格

How to Choose Different Gold Mines Beneficiation Technologies?

2024年2月12日 Mercury amalgamation technology is an older gold mines extraction technology with a simple process and low cost. It is mainly used for the recovery of coarse single gold particles. ... it is recommended to conduct beneficiation tests to determine the characteristics and properties of gold ore, and customize a beneficiation plan to improve

获取价格

Beneficiation (Metallurgy) - an overview ScienceDirect Topics

Technical comparisons are often drawn between jigging and DMS as alternative methods for iron ore beneficiation. ... Cordos et al., 2003; UNEP/OCHA, 2000) found extremely high levels of copper, lead, mercury, cadmium, and zinc in sediments close to the mining site. All concluded that, although the tailings solids and waters had contaminated the ...

获取价格

Valorization From Waste: Combined Reduction of Chromite Ore

2024年1月10日 Chromite ore processing tailings and low-grade manganese ores are typically considered waste due to their limited or negligible utility, leading to environmental and storage concerns. ... which brings challenges to the selection and identification of suitable beneficiation processes for the ore ... (vi) and mercury (ii) – implications in ...

获取价格

Ore Beneficiation - an overview ScienceDirect Topics

Iron ore beneficiation can be brought about through three approaches, namely, selective dissolution, microbially induced flotation, and selective flocculation–dispersion. The bioprocesses are specially suited to treat fines, slimes, and waste tailings. 4. Potential applications include.

获取价格

How to Choose Different Gold Mines Beneficiation Technologies?

2024年2月12日 Mercury amalgamation technology is an older gold mines extraction technology with a simple process and low cost. It is mainly used for the recovery of coarse single gold particles. ... it is recommended to conduct beneficiation tests to determine the characteristics and properties of gold ore, and customize a beneficiation plan to improve

获取价格

Beneficiation (Metallurgy) - an overview ScienceDirect Topics

Technical comparisons are often drawn between jigging and DMS as alternative methods for iron ore beneficiation. ... Cordos et al., 2003; UNEP/OCHA, 2000) found extremely high levels of copper, lead, mercury, cadmium, and zinc in sediments close to the mining site. All concluded that, although the tailings solids and waters had contaminated the ...

获取价格

An Examination and a Solution to replace the use of Mercury in ...

2023年3月23日 It is well documented that whole ore mercury amalgamation Chilean processing centers use of mercury in ore processing to recover gold is the Planet’s largest anthropogenic source of local biodiversity destruction, human health threats, and deadly global atmospheric mercury pollution which is documented in 2021 by Oxford University

获取价格

Beneficiation: Quality Starts with the Ore — Metals Magazine

2017年2月1日 By enhancing the quality of lower-grade raw materials through beneficiation, downstream processes also become more viable. Various production routes are available to transform iron ore into liquid steel, as shown in Figure 1. The selected route depends to a large extent on the quality of the iron ore, energy source and related costs.

获取价格

DO YOU KNOW HOW TO IMPROVE THE GRADE OF MERCURY ORE

2021年8月23日 OVERVIEW ROM of Mercury Ore Cinnabar is red, with high density, brittleness, and good natural floatability. Several methods such as pre-selection, gravity beneficiation, and flotation can be used ...

获取价格

Mercury Ore Processing Line - Henan Forui Machinery

The structure of mercury ore is complex, with grained embedded , speckled and lumpy forms. For massive mercury ores, a single gravity separation can achieve high beneficiation index. For speckled mercury ore, high beneficiation index can be obtained by flotation. For speckled low-grade mercury ore, a combined gravity beneficiation

获取价格

Chrome ore beneficiation challenges opportunities – A review

2011年4月1日 Abstract. Supply of world chromite (chrome ore) has come under severe pressure over the past year driven by strong demand for ferrochrome used in ferroalloy production for making stainless steel. Many of the strategic minerals are inputs into products in fast-changing markets. This article reviews the major process flow sheets in practice for

获取价格

Recent Trends in Phosphate Mining and Beneficiation and

2019年4月30日 The process includes an apatite ore beneficiation by flotation and further processing of the beneficiation concentrate with sulfuric acid. Twenty-six, sixty-two and twelve percent of the total REOs (TREO) contents from the ore end up in the products of beneficiation tailings, phosphogypsum (PG) and phosphoric acid, respectively.

获取价格

Mineral beneficiation and ore dressing - Unacademy

Benefits of Mineral Beneficiation. The benefits of mineral beneficiation or ore dressing are as follows: High volume production in lesser time. Increases the metal content of the ore. Decreases the gangue content to get the most out of the ore. It provides raw materials that support the country’s infrastructure and economy.

获取价格

Beneficiation ore PDF - SlideShare

2014年10月9日 The United States imported 12.9 million lt of usable iron ore in 1991 for beneficiation and processing. According to the U.S. Bureau of Mines "usable" iron ore implies that less than 5 percent of the material is made up of manganese (U.S. DOI, Bureau of Mines 1991a).

获取价格

Beneficiation of Iron Ore - 911 Metallurgist

2016年5月24日 Beneficiation of Iron Ore and the treatment of magnetic iron taconites, stage grinding and wet magnetic separation is standard practice.This also applies to iron ores of the non-magnetic type which after a reducing roast are amenable to magnetic separation. All such plants are large tonnage operations treating up to 50,000 tons per

获取价格

Combined microflotation effects in polymetallic ores beneficiation ...

2023年4月2日 Producing of heterogeneous concentrates with good recovery in the processing of polymetallic ores is a challenge. Many factors must be taken into account including ore grinding, reagent mode, water composition, pulp density and the volume of supplied bubbles when producing high-quality selective concentrates. Microbubbles

获取价格