equipments to produce silicon from sand

From Sand to Silicon - Intel

Sand – especially Quartz - has high percentages of Silicon in the form of Silicon dioxide (SiO 2) and is the base ingredient for semiconductor manufacturing. Melted Silicon – scale: wafer level (~300mm / 12 inch) Silicon is purified in multiple steps to finally reach

获取价格

From Sand To Wafers - Semiconductor Engineering

2019年4月18日 The starting material really is sand. Not just any sand, but silica sand, specially quarried for this purpose and having concentrations

获取价格

The Importance of New “Sand-to-Silicon” Processes for the

Alternative Low Temperature “Sand-to-Si” Processes. Avoiding carbothermal reduction inherently changes infrastructure requirements (e.g., electrical power consumption,

获取价格

Making silicon from sand Popular Science

2005年10月17日 All you have to do is heat a mixture of common silica sand and magnesium powder in a test tube. The magnesium steals the oxygen atoms from the silica, leaving elemental silicon.

获取价格

Mining And Refining: Pure Silicon And The Incredible Effort

Hard as RockMore NinesOne Crystal Only, PleaseThe raw material for most silicon production is the mineral quartzite. Quartzite comes from ancient deposits of quartz sands that formed sedimentary deposits. Over time and with heat and pressure, these quartz sandstones were transformed into the metamorphic rock quartzite, which is at least 80% quartz by volume. Qu在hackaday上

Silicon Wafer Manufacturing: From Sand to Silicon

2023年3月21日 Silicon wafer processing refers to the manufacturing steps involved in producing high-quality silicon wafers for use in semiconductor devices such as microprocessors, memory chips, and sensors. The

获取价格

From sandy beach to Kaby Lake: How sand becomes

2016年8月25日 There are more than 300 steps to turn sand into silicon, but you can group them into 10 key areas. If you can't imagine how the stuff you make sandcastles with can become a Kaby Lake...

获取价格

New process creates silicon-based chemicals from sand

2000年11月14日 ANN ARBOR—Building on his own past research, Richard Laine, University of Michigan professor and materials scientist, has discovered an inexpensive

获取价格

From Sand to Silicon: The Making of a Microchip Intel

观看视频4:452020年2月18日 Ever wonder what’s under the hood of your favorite electronic device? The transistor is the engine that powers every Intel processor. To build a modern compu...

获取价格

From Sand to Silicon Intel - YouTube

2020年6月24日 From Sand to Silicon Subscribe now to Intel on YouTube: https://intel.ly/3IX1bN2 About Intel: Intel, the world leader in silicon innovation, develops

获取价格

The Ultra-Pure, Super-Secret Sand That Makes Your

2018年8月7日 Spruce Pine, it turns out, is the source of the purest natural quartz—a species of pristine sand—ever found on Earth. This ultra‑elite deposit of silicon dioxide particles plays a key role ...

获取价格

Extraction and Synthesis of Silicon Nanoparticles

2022年2月23日 This current study reviews the utilization of the traditional extraction methods and latest findings in extraction of silica from agricultural wastes, in particular, sugarcane bagasse, using inorganic acids to

获取价格

How sand is transformed into silicon chips - Ultra HPQ

2009年5月24日 This is accomplished by heating a mixture of silica and carbon in an electric arc furnace to a temperature in excess of 2,000°C. The carbon reacts with the oxygen in the molten silica to produce carbon

获取价格

Why the world is running out of sand - BBC

2019年11月17日 Demand for high-purity silica sands, which are used to make glass as well as high-tech products like solar panels and computer chips, is also soaring. America’s surging fracking industry also ...

获取价格

From sandy beach to Kaby Lake: How sand becomes silicon

2016年8月25日 Step 2: Make some crystals. Electronic-grade silicon still isn't perfect, because it has a polycrystalline structure. That means it's composed of lots of small silicon crystals, and the joins ...

获取价格

Production of metallurgical-grade silicon from Egyptian quartz

2018年2月1日 Then the analysis of silica sand concentrate reveals 98.80% SiO2 with 0.40% Al2O3, 0.06% Fe2O3, 0.03% TiO2 and 0.38 LOI. These techniques concern low coastlines to start out the metal-silicon ...

获取价格

What Is Silicone? How Is It Made? - Wafer Process Systems

2020年1月23日 Instead, people produce silicon via one of two ways – either from sand (silicon dioxide) or from vein or lode deposits within the earth. When producing pure silicon from sand, manufacturers heat it at 2200 degrees Celsius. At that temperature, the pure crystalline silicon separates, and it becomes a compound that people can turn into wafers.

获取价格

Refining Silicon PVEducation

The silica is reduced (oxygen removed) through a reaction with carbon in the form of coal, charcoal and heating to 1500-2000 °C in an electrode arc furnace. SiO 2 + C → Si + CO 2. The resulting silicon is metallurgical grade silicon (MG-Si). It is 98% pure and is used extensively in the metallurgical industry.

获取价格

How Does Sand Become Silicon? CPU Manufacturing Explained - MUO

2022年5月27日 The base ingredient of any processor, silicon, is extracted from desert sand. This material is found abundantly in the earth's crust and consists of around 25% to 50% silicon dioxide. It is processed to separate silicon from all other materials in the sand. The processing repeats several times until the manufacturer creates a 99.9999% pure

获取价格

Silicon seduced from silica Nature

2003年5月19日 Silica is melted in a furnace at around 1,700 °C and is reacted with carbon to produce impure silicon. The high-quality silicon in chips is made by melting chemically purified silicon and letting ...

获取价格

Six crucial steps in semiconductor manufacturing – Stories ASML

2023年10月4日 The process begins with a silicon wafer. Wafers are sliced from a salami-shaped bar of 99.99% pure silicon (known as an 'ingot') and polished to extreme smoothness. Thin films of conducting, isolating or semiconducting materials – depending on the type of structure being made – are deposited on the wafer to enable the first layer to

获取价格

High Purity Quartz Sand: What Is It Used for and How to Get It?

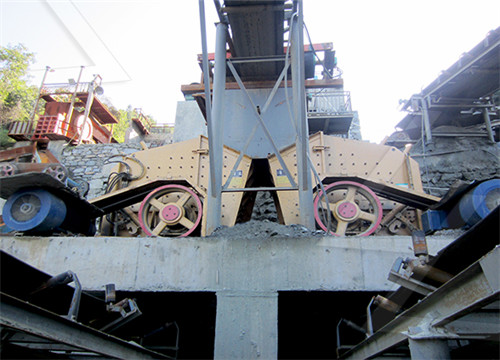

2023年4月11日 The high purity quartz sand (HPQ) is one of the main materials in the silica and silicon industry field. It is produced by the crystal, quartz sandstone, and vein quartz, powder quartz, granite quartz through and by the processing and creating ways of crushing, grinding, classification, sorting, chemical washing, beneficiation leaching, thermal ...

获取价格

How are Semiconductors Made? A Comprehensive Guide to

2023年6月2日 7. Etching Process. The etching process is an essential step in semiconductor fabrication used to remove selected layers from the surface of a silicon wafer. It allows the creation of intricate patterns that form the basis for the miniaturized circuits present in the electronic devices.

获取价格

The Importance of New “Sand-to-Silicon” Processes for the

The only argument against crystalline Si as the ideal PV material both now and in the future pertains to the fourth criterion. That is, the availability, collection, and manufacture of crystalline Si are extremely problematic. More precisely, because Si in nature is found only as impure, oxidized sand (silica/SiO 2) or silicates (a salt with SiO 4–x (4–2x)–), the

获取价格

Six crucial steps in semiconductor manufacturing – Stories ASML

2023年10月4日 The process begins with a silicon wafer. Wafers are sliced from a salami-shaped bar of 99.99% pure silicon (known as an 'ingot') and polished to extreme smoothness. Thin films of conducting, isolating or semiconducting materials – depending on the type of structure being made – are deposited on the wafer to enable the first layer to

获取价格

High Purity Quartz Sand: What Is It Used for and How

2023年4月11日 The high purity quartz sand (HPQ) is one of the main materials in the silica and silicon industry field. It is produced by the crystal, quartz sandstone, and vein quartz, powder quartz, granite quartz through

获取价格

How are Semiconductors Made? A Comprehensive

2023年6月2日 7. Etching Process. The etching process is an essential step in semiconductor fabrication used to remove selected layers from the surface of a silicon wafer. It allows the creation of intricate patterns that

获取价格

The Importance of New “Sand-to-Silicon” Processes for the

The only argument against crystalline Si as the ideal PV material both now and in the future pertains to the fourth criterion. That is, the availability, collection, and manufacture of crystalline Si are extremely problematic. More precisely, because Si in nature is found only as impure, oxidized sand (silica/SiO 2) or silicates (a salt with SiO 4–x (4–2x)–), the

获取价格

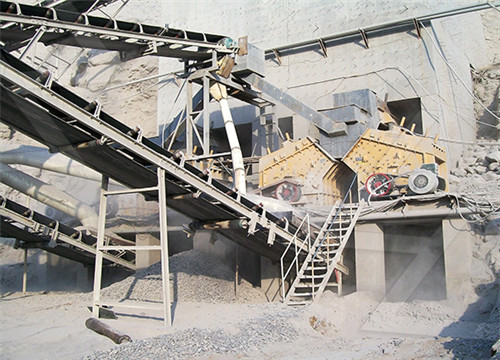

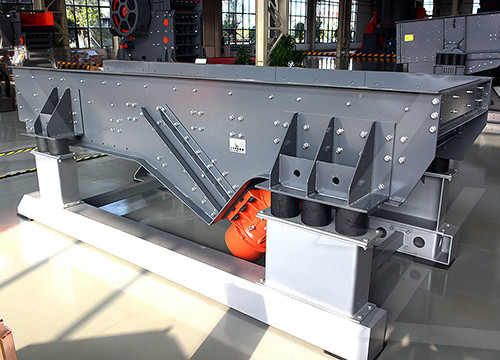

Silica Processing Plant 4 Major Stages to Make Silica Sand

2023年8月10日 It can effectively regulate the liquid level, increase the degree of refinement of the foam, and improve the flotation of the equipment. 4. Silica sand drying process. Dry the purified silica sand to reduce its water content to a certain level. Pack the selected silica sand for easy storage and transportation.

获取价格

Silicon From Sand Educational Innovations

2011年3月2日 Silicon is the second most abundant element in the earth’s crust (27.7%) – only oxygen beats it – and can easily be extracted from white sand (SiO 2) in a spectacular reaction in the school science laboratory. Thermite Reactions. In Thermite reactions metal oxides react with aluminum to produce the molten metal.

获取价格

How Are Solar Panels Made? - Union of Concerned Scientists - The

2022年10月19日 Silicon, in the form of silicon dioxide sand and gravel, is the second most abundant element on Earth, next to oxygen. Before it’s used in a solar panel, silicon dioxide must be turned into pure “metallurgical grade silicon” (MGS). This process uses a lot of energy: producing 1 kilogram of metallurgical grade silicon requires 14-16 kWh of ...

获取价格

From Sand to Silicon: The Making of a Microchip - Intel

It’s one of mankind’s most complex feats, and it’s happening every day across Intel’s global network of chip manufacturing facilities. Check out this video to learn more about how we turn sand into the silicon chips that power the world. More: Manufacturing at Intel. » Download video: “From Sand to Silicon: The Making of a Microchip”.

获取价格

How Silica Sand is Used in Glass Manufacturing PFS Aggregates

2021年4月7日 The following is the process for making flat glass, which is commonly produced with silica sand. Batched – The main components, including the silica sand, limestone, soda, and recycled glass, are weighed and sorted into batches. Melted – The batched raw materials enter a furnace that reaches temperatures up to 1600°C and

获取价格

How to Make Silicon Crystals from Sand Sciencing

2017年4月25日 Remove from heat priot to purifying the mixture with an acid solution. Pour 5 cups of cold water into a large laboratory flask. Add 1 cup of muriatic acid. Do not reverse these steps -- the acid must be added to the water. Let the test tube cool for five minutes. Add the contents to the flask, using a funnel if the flask mouth is not wide enough.

获取价格

Silicone: A Guide to Production, Uses and Benefits - SIMTEC

2022年12月11日 Step 1: Isolate Silicon From Silica. Isolating silicon from silica is the first step in producing silicone. To achieve this, a large volume of quartz sand is heated to temperatures as high as 1800 degrees Celsius. Pure, isolated silicon is the result. Once it cools, manufacturers can grind it into fine powder.

获取价格

A facile and universal method to purify silica from natural sand

The major constituents of sand are silica and silicates. The facile and low-cost purification technology of silica from natural sand is of magnificent importance to the industrial applications of silicon-based materials. Herein, we report a green, low-cost, and universal method to purify silica from natural sand. Sand from deserts, rivers, and seas is selected

获取价格

Everything You Need to Know About Silicon Wafer Manufacturing

Purification and making an ingot are arguably the most important steps in silicon wafer manufacturing, these two processes are complex but can be summed up in the following steps: Melting the silicon. Add the seed crystal. Grow the crystal by rotating it in the crucible. Pull the crystal from the crucible. Extract the fully formed crystal with ...

获取价格

Our technology products ASM

From sand to silicon It all starts with one simple, common substance – sand. The silicon found in sand is in the form of silicon dioxide. ... Our equipment is essential to produce the electronic products that consumers and businesses use everywhere, from the highly specialized to the everyday. In doing so, our products enable the ...

获取价格