separation force two roll grinding mill

Deformation Processing - Rolling - IIT Bombay

Rolling Analysis. Objectives. Find distribution of roll pressure. Calculate roll separation force (“rolling force”) and torque. Processing Limits. Calculate rolling power.

获取价格

Rolling - IIT Bombay

The rolling mill is adequate if the required power for the operation is less than or equal to the available power. Power required per roll, 60000 FLN P roll p ¢ = kW Roll separating

获取价格

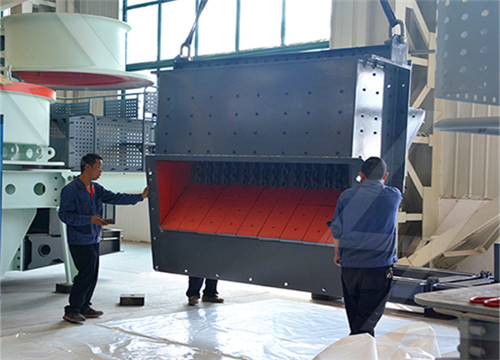

Grinding Contribution and Quantitative Separation of Impact

2023年8月3日 In summary, the paper proposes for the first time a new grinding analysis method that quantitatively separates and characterizes the grinding contribution of the

获取价格

Comparison of different comminution flowsheets in terms of

2018年8月15日 Comparative mineral liberation and separation tests of hematite ores were conducted for three comminution flowsheet options to produce relatively fine products at the 70% and 90% passing 74 µm: Option A uses a high pressure grinding roll (HPGR) with screening and subsequent ball milling, Option B uses an HPGR with an air classification,

获取价格

Roller mills: Precisely reducing particle size with greater

roll pair, as shown in Figure 2. More about the rolls. Common roll diameters are from 6 to 10 inches, and roll lengths — which vary with the roll diameter to ensure that the roll will be mechanically robust — are from 8 to 52 inches. Longer rolls provide greater grinding capacity. The more roll pairs the mill has, the greater the size

获取价格

Replacement of Wet Ball Milling with High-Pressure Grinding

2023年11月28日 In response to the Natural Resources Canada “Crush It Challenge,” Corem partnered with the University of British Columbia and led a project to develop and demonstrate the use of high-pressure grinding to replace the workhorse of the industry, wet ball milling. Two plant case studies, a small tonnage gold recovery operation and a large

获取价格

Chapter 10 Selection of Fine Grinding Mills - ScienceDirect

2007年1月1日 Figure 3 shows the schematic diagram of one of the axial flow-type impact mills called a Super Micron Mill E. This mill has a larger processing volume and operated at a middle-range speed but is capable of the finer grinding by the attrition mechanism and separation nozzle to discharge foreign materials, which often cause the reduction in the

获取价格

HPGR High Pressure Grinding Rolls - 911 Metallurgist

2016年7月13日 A Cerro Verde expansion used a similar flowsheet as the 2006-commissioned circuit to triple circuit capacity. The expansion circuit includes eight MP1250 cone crushers, eight HPGRs (also 2.4 x 1.7-m units, with 5 MW each), and six ball mills (22 MW each), for installed comminution power of 180 MW. and a nameplate capacity of

获取价格

A comprehensive review on incremental deformation in

2022年2月15日 Feed angles on the rolls were between 8° and 16° determined by Zhao et al. in 2014. Through the experiment, Pater et al. found 3-roll mills were 30% faster than 2-roll mills to produce thick tubes as the circumferential flow is increased in 2-roll mills at the surface layer, consuming more time and affecting both strains and energy consumption.

获取价格

Energy-Efficient Technologies in Cement Grinding IntechOpen

2016年10月5日 The energy consumption of the total grinding plant can be reduced by 20–30 % for cement clinker and 30–40 % for other raw materials. The overall grinding circuit efficiency and stability are improved. The maintenance cost of the ball mill is reduced as the lifetime of grinding media and partition grates is extended. 2.5.

获取价格

Study on the Life of Hydrocyclones for Cleaning Coolant on Roll ...

2023年8月4日 The object of the study is hydrocyclones for coolant cleaning of models X45–33 and X45–23. According to the certificate, hydrocyclones are designed for purification of coolant from mechanical impurities with volume weight up to 2 g/cm 3 and size not exceeding 2 mm in grinding, honing and other machine tools.

获取价格

Raw Material Drying-Grinding - Cement Plant Optimization

Ball mills for cement raw material and coal equipped with a drying compartment adequately air swept with hot gas (2.5-3.5M/sec above the ball charge), can handle moisture about 8%. Fully air- swept mills (5-6M/sec) can dry up to 12-14% moisture. Grinding Operation Objectives and KPIs: Highly energy intensive unit operation of size reduction in ...

获取价格

Mineral Processing Design and Operations ScienceDirect

The designs of autogenous and semi-autogenous (SAG) grindings mills are described followed by the description of their methods of operation in grinding circuits involving crushers and ball mills. Methods of estimating SAG mill volumes, mill charges, feed size and power consumptions and optimum speeds of rotation during operation are described.

获取价格

Ball Mill - an overview ScienceDirect Topics

With dry grinding, these mills often work in a closed cycle. A scheme of the conical ball mill supplied with an air separator is shown in Fig. 2.13. Air is fed to the mill by means of a fan. Carried off by air currents, the product arrives at the air separator, from which the coarse particles are returned by gravity via a tube into the mill.

获取价格

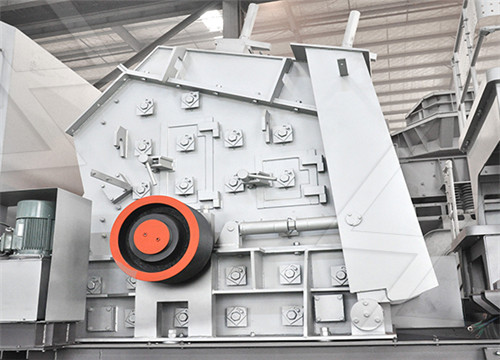

Revolution of Grinding Mill (Roller Body), Design, Operation ...

2019年6月3日 Common parts of a Roller Body. 1. Break roll feed box. 2. Feed inlet. 3. Middle wall. 4. Impulse transmitter. 5. Feed gate segment. 6. Feeding device. 7. Break feed roll

获取价格

The Evolution of Milling Process SpringerLink

2021年4月20日 It is supposed that the mills consisting of two grindstones appeared in ancient Egypt but the archaeological finds from 1000 BC at the Boden Lake in modern Switzerland and around Dresden and Leipzig in modern Germany also reported similar grinding stones [7, 12].Very important feature of this grinding instrument is a shift from

获取价格

Size reduction performance evaluation of HPGR/ball mill and

2023年1月1日 The specific pressing force is the grinding force exerted on the floating roll. It is usually expressed as the grinding force applied to the rolls divided by the diameter and width of roll. F sp = F D × L 10-3. where, F sp (MPa), F (kN), D (m) and L (m) are specific pressing force, the total pressing force exerted, roll diameter, and roll ...

获取价格

Ball Mill - an overview ScienceDirect Topics

With dry grinding, these mills often work in a closed cycle. A scheme of the conical ball mill supplied with an air separator is shown in Fig. 2.13. Air is fed to the mill by means of a fan. Carried off by air currents, the product arrives at the air separator, from which the coarse particles are returned by gravity via a tube into the mill.

获取价格

Revolution of Grinding Mill (Roller Body), Design,

2019年6月3日 Common parts of a Roller Body. 1. Break roll feed box. 2. Feed inlet. 3. Middle wall. 4. Impulse transmitter. 5. Feed gate segment. 6. Feeding device. 7. Break feed roll

获取价格

The Evolution of Milling Process SpringerLink

2021年4月20日 It is supposed that the mills consisting of two grindstones appeared in ancient Egypt but the archaeological finds from 1000 BC at the Boden Lake in modern Switzerland and around Dresden and Leipzig in modern Germany also reported similar grinding stones [7, 12].Very important feature of this grinding instrument is a shift from

获取价格

Size reduction performance evaluation of HPGR/ball mill and

2023年1月1日 The specific pressing force is the grinding force exerted on the floating roll. It is usually expressed as the grinding force applied to the rolls divided by the diameter and width of roll. F sp = F D × L 10-3. where, F sp (MPa), F (kN), D (m) and L (m) are specific pressing force, the total pressing force exerted, roll diameter, and roll ...

获取价格

(PDF) RECENT ADVANCES ON 20-HI CLUSTER MILL

2011年5月25日 A 20-hi cluster mill is simply a precision mill used to roll ultra-thin and/or ultra-high-strength material. The conventional monoblock mill provides the greatest mill modulus among all types of ...

获取价格

Instability of roll nonlinear system with structural clearance in ...

2022年8月1日 The vibration instability of the nonlinear dynamic system of the rolls considering the structural clearance was theoretically investigated, which is caused by the roll assembly accuracy deviation in the hot rolling process. Firstly, the dynamic rolling force model was established based on the Цeликoв model under the influence of the roll

获取价格

Size Reduction-1: Grinding – Unit Operations in Food Processing

30.4.1.3 Crushing rolls . Smooth-roll crushers: Two heavy smooth-faced metal rolls rotating on parallel horizontal axes are the working elements of the smooth-roll crusher illustrated in Fig. 30.4.The rolls rotate toward each other at the same speed. Feed materials are caught between the rolls and broken in compression and then drop out below.

获取价格

Mineral Processing Design and Operations - Google Books

Elsevier, May 2, 2016 - Science - 882 pages. Mineral Processing Design and Operations: An Introduction, Second Edition. This second edition describes theories and practices of design and operation of apparatus and equipment, including an additional chapter on magnetic, electrostatic, and conductivity modes of mineral separation.

获取价格

(PDF) SIZE REDUCTION BY GRINDING METHODS - ResearchGate

2017年3月4日 The process Comminution involves size reduction and size-wise classification called as screening/ separation. Milling is one of the most important industrial processes. The electric power ...

获取价格

Deformation Processing - Rolling - IIT Bombay

– Find distribution of roll pressure – Calculate roll separation force (“rolling force”) and torque – Processing Limits – Calculate rolling power. Prof. Ramesh Singh, Notes by Dr. Singh/ Dr. Colton 13 Flat Rolling Analysis • Consider rolling

获取价格

A Basic Understanding of the Mechanics of Rolling Mill Rolls

Separation force in a mill is calculated as force to reduce the cross section of rolled material plus friction between rolls and rolled material. And vice versa, it is state-of-the-art to calculate friction from the calculated and measured separating force. It was found (see chapter 4.8.3) that the friction changes during a rolling campaign.

获取价格

Roll Mill - an overview ScienceDirect Topics

4.2.3.1.1 Roll Mills. The roll mill is the simplest batch mixing equipment. The principal design consists of two horizontal rolls, usually of equal size, arranged side by side and rotating toward each other at different speeds. The ratio of the peripheral speeds of the rolls, known as friction ratio, ranges from 1 to 2 but is usually around 1.2 ...

获取价格

Rolling - IIT Bombay

The rolling mill is adequate if the required power for the operation is less than or equal to the available power. Power required per roll, 60000 FLN P roll p ¢ = kW Roll separating force, ( ) ÷ ÷ ø ö ç ç è æ ÷÷ + ø ö çç è æ = avg avg f h L F Lw Y 2 1 3 2 µ L= RDh= (0.375)(0.075-0.06)=0.075 m 0.0675 2 0.075 0.06 = + h avg = m ...

获取价格

Grinding and Dispersion Equipment For Nano Scale

a particle size as circulation grinding on a pin mill at 4.3 minutes of residence time and 256 kWhrs/ton Espec. The pin mill’s larger separation system allows much higher flow rates than the disc mill. Graph 1: Disc mill vs. Zeta mill, grinding phthalo blue pigment Unlike deagglomeration, in which primary particle size

获取价格