two stage crushing facility

RHI Magnesita's York, Pennsylvania refractory

2021年6月3日 The custom-designed, two-stage primary crushing system incorporates advanced technology to increase efficiency, optimise maximum material recovery, and reduce waste. In more detail, the system has a

获取价格

Crushing Plant Design and Layout Considerations - 911

There are three main steps in designing a good crushing plant: process design, equipment selection, and layout. The first two are dictated by production requirements and design

获取价格

Crushing Plant Design and Layout Considerations

2 Considerations of crushing plant layout 2.1 Two stages of crushing flow sheet. The crushed product obtained by the two-stage open crushing

获取价格

Why it pays off to invest in multi-stage crushing process

2020年8月11日 Two of the most common crushing applications are two- and three-stage crushing processes. When deciding on whether to have two or three crushing stages, certain factors need to be considered in

获取价格

Single VS Multi-Stage Crushing - 911 Metallurgist

18 行 2016年2月28日 Single VS Multi-Stage Crushing. There are no set rules for determining whether the secondary stage should consist of one single crusher, or of two

获取价格

Architecture and Engineering Volume Issue - ResearchGate

The advantage of two-stage crushing schemes is shown, which makes it possible to ensure a change in the ratio of large aggregate fractions within fairly wide limits.

获取价格

Quantify effects of stage crushing on dimensional ... - Springer

2019年9月3日 Both crushing mechanisms represents wide range of crushers and stage of crushing (i.e. JH and JJHV as two-stage: 2S and four-stage: 4S, respectively). The

获取价格

Crushing Plant Capacity - 911 Metallurgist

2016年2月26日 From 10 to 15% will usually be safe, if the crushing plant is designed for one-shift operation. Underground mining operations without surge capacity ahead of the primary should be figured for at least 25%

获取价格

DESIGN, INNOVATION AND FUNCTIONALITY OF MEKA

2023年3月6日 DESIGN, INNOVATION AND FUNCTIONALITY OF MEKA TWO STAGE. MEKA takes extreme pride in being selected by our customer for the complete supply of a new installation. MPD 900 is a wheel

获取价格

Why it pays off to invest in multi-stage crushing process

2020年8月11日 Three stage crushing process with C120 jaw crusher, GP300S secondary cone crusher and GP330 cone crusher. A more open CSS of the jaw increases the capacity of the plant, and the feed flows

获取价格

Crushing Plant Design and Layout Considerations

The two-stage crushing and over two stages crushing is a combination of different crushing stages, so there are many possible schemes. ... At this point, the washing facility should be added to the crushing process.

获取价格

sbm/sbm two stage crushing facility.md at main dihog/sbm

Contribute to dihog/sbm development by creating an account on GitHub.

获取价格

Quantify effects of stage crushing on dimensional ... - Springer

2019年9月3日 The present study evaluates the effects of two different aggregate production (crushing) mechanism, i.e. Jaw-Horizontal Shaft Crusher (HSI) named as JH and Jaw-Jaw-HSI-Vertical Shaft Impact Crusher (VSI) known as JJHV on aggregate dimension distribution. Both crushing mechanisms represents wide range of crushers

获取价格

AMIT 135: Lesson 6 Grinding Circuit – Mining Mill Operator

Objectives. At the end of this lesson students should be able to: Explain the grinding process. Distinguish between crushing and grinding. Compare and contrast different type of equipment and their components used for grinding. Identify key variables for process control. Design features of grinding equipment (SAG, BALL and ROD MILLS)

获取价格

Avesoro Youga Balogo Gold Mines

The Balogo Project is covered by two contiguous Exploration Permits (Balogo and Dabinyan III) Processing Plant. The processing plant at Youga consists of three-stage crushing and a single ball milling circuit followed by gravity, cyanide leaching and a five-stage CIL circuit and electrowinning to produce dore bars; nameplate capacity is 1.1Mtpa.

获取价格

DEFINITIVE FEASI ILITY STUDY

2023年6月29日 development. Stage 2 includes the evaluation of a Feldspar circuit, a by-product of the DMS process that we intend to supply to the local Ghanaian ceramics market, and a Flotation circuit, further enhancing the Project’s economics. “Ewoyaa’s favourable mineralogy enables a simple flowsheet comprising a 3-stage crushing facility and

获取价格

sbm/sbm two stage crushing facility portable sand making

Contribute to changjiangsx/sbm development by creating an account on GitHub.

获取价格

Agriculture Free Full-Text Process Analysis and Parameters

2022年12月8日 The application of the conventional vibrating screen to the separation of the black soldier fly (BSF) sand mixture has several problems (e.g., high rate of impurity and low efficiency). A two-stage sieve surface vibratory sorting device with combined planar and curved surfaces was investigated, and its critical operating parameters were determined.

获取价格

Tertiary roll crusher development. Interim report - OSTI.GOV

Under this concept, fuel elements are crushed to ring-size particles smaller than 3/16 in. (4.8 mm) while minimizing the breakage of TRISO-coated fuel particles. Conventional equipment has been evaluated for the primary and secondary crushing steps. This report evaluates roll crushers that are proposed for the tertiary and final stage of ...

获取价格

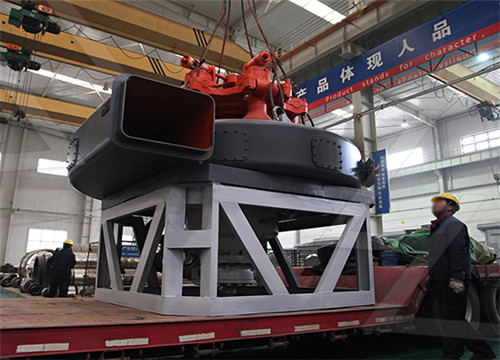

Double Stage Crusher - Fodamon Machinery

The two-stage crusher can easily crush the material like coal gangue, shale and coal cinder, etc. A two-stage crushing machine is equivalent to the combination of two hammer crushers. Why choose the Fodamon two stage crushing machine? 1. If the hammer is severely battered, you do not need to repair or change with a new one.

获取价格

The Complete Guide to Tunnel Slag Treatment - sbmchina

2023年4月26日 For coarse crushing, jaw crusher or gyratory crusher is often used. For medium crushing, medium-sized cone crusher with a relatively large crushing ratio is used, while for fine crushing, a short head cone crusher is used. For medium or fragile rocks like limestone and marble, two-stage or three-stage crushing process can be used.

获取价格

Canola growth in Saskatchewan predicted to match crushing facility ...

2022年6月21日 Leftwich told farmnewsNOW. The spring of 2021 was the year of canola crush facility announcements as one company after another announced new and expanding facilities with state-of-the-art transportation and efficient processing systems. Cargill will be developing a $350-million project in Regina, Sask. Announced in April

获取价格

Viterra plans to build supersized canola crush plant in Regina ...

2021年4月27日 Ag network company Viterra plans to build a new canola crushing facility in Regina, Saskatchewan. The company says it’s in the feasibility stage to finalize the plant’s capabilities and design. The initial targeted annual crush capacity of the project is 2.5 million metric tons. If plans materialize, Viterra says this would be the world’s ...

获取价格