coal grinding processes

Coal grinding technology: a manual for process engineers.

The handbook is not intended to be an exhaustive guide to design and practice since separate books could be written on each system. Instead it is a guide for the process

获取价格

Optimization of operating conditions on ultra-fine coal grinding ...

2022年5月1日 This study investigated ultra-fine coal grinding performance of four low- to moderate-cost grinding media in a laboratory stirred mill. Kinetic grinding tests showed

获取价格

How A Coal Pulverizer Works - Coal Grinding Process - YouTube

观看视频4:592010年2月23日 Here’s a 3D animation of how a coal grinding system works. Williams Crusher has the most advanced direct fired coal and pet coke pulverizing system in the fi...

获取价格

Design of coal preparation plants: problems and solutions

During the process of coal transportation from the mine (open cast) to the CPP the coal grinding occurs. Its composition varies in both size and quality of individual size grades.

获取价格

(PDF) Improving the efficiency of the coal grinding

2022年2月24日 process: 1 – drum feeder; 2 – coal supply; 3 – ball drum mill; 4 – cyclone; 5 – granular filter; 6 – centrifugal fan; 7 – electric drive; 8 – control panel

获取价格

Production of Ultra-Clean Coal by the Combined Method of

2022年12月19日 In this paper, the combined method of grinding and the collector gasification flotation method was used to obtain ultra-clean coal. The effects of grinding

获取价格

A Study on the Hard Coal Grindability Dependence on

2021年12月5日 Abstract: A very important aspect of proper preparation of the coal mixture for the coking process is its appropriate grinding. One of the parameters describing the

获取价格

Energies Free Full-Text A Study on the Hard Coal

2021年12月5日 Determining the properties of coal, in particular, the grindability, is of great importance because coal graining plays a huge role in each use of coal: combustion, gasification, enrichment and

获取价格

Developing/modifying coal grinding procedures predictable size ...

@article{osti_6501545, title = {Developing/modifying coal grinding procedures predictable size distributions during coal preparation}, author = {Luckie, P. T.}, abstractNote = {The

获取价格

DISCUSSION ON SAFETY PRODUCTION OF COAL MILLING

2022年1月27日 The burn-up of coal in cement production requires the support of a coal grinding system. In the current cement production process, a large amount of fuel is also required as a guarantee, and coal ...

获取价格

Processes Free Full-Text Production of Ultra-Clean

2022年12月19日 The preparation and application of ultra-clean coal is one of the important aspects of clean energy technology. However, the preparation of ultra-clean coal is mainly chemical methods, which are low

获取价格

Method of removing ash components from high-ash content coals

Abstract. A method of removing ash components from coals, particularly high-ash content coals, comprises grinding the coal into ground particles and suspending the ground coals in an aqueous alkali carbonate solution. The solution is maintained in a reactor for 45 to 120 minutes at a temperature range of from 250 to 280/sup 0/C and under a ...

获取价格

Optimization of Operating Conditions and Design Parameters

Ultra-fine grinding is an energy-intensive process that usually results in operational inconvenience due to the high operating costs associated with energy consumption. Nevertheless, it plays a vital ... The optimization of ultra-fine coal grinding performance using a laboratory scale stirred mill was

获取价格

(PDF) Improving the efficiency of the coal grinding process in ball ...

2022年2月24日 Improving the efficiency of the coal grinding process in ball drum mills at thermal power plants February 2022 Eastern-European Journal of Enterprise Technologies 1(1 (115)):93-105

获取价格

Energies Free Full-Text A Study on the Hard Coal ... - MDPI

2021年12月5日 A very important aspect of proper preparation of the coal mixture for the coking process is its appropriate grinding. One of the parameters describing the energy input required for grinding is the Hardgrove index. This research was undertaken to determine the dependence of the Hardgrove grindability index on selected

获取价格

Basic knowledge about coal preparation - LinkedIn

2017年7月14日 Coal preparation includes blending and homogenization, size reduction, grinding, screening and handling. The most important step is coal beneficiation or cleaning. ... Coal preparation process ...

获取价格

Energy-Efficient Technologies in Cement Grinding IntechOpen

2016年10月5日 The energy consumption of the total grinding plant can be reduced by 20–30 % for cement clinker and 30–40 % for other raw materials. The overall grinding circuit efficiency and stability are improved. The maintenance cost of the ball mill is reduced as the lifetime of grinding media and partition grates is extended. 2.5.

获取价格

Generation of low ash fine clean coal powder by autogenous grinding

2019年1月15日 In conventional coal grinding process, coal is grinded mainly using the hammer mills, where due to the high impact force, the maceral and minerals homogenously due to breakage function [[12], [13], [14]]. It was shown that, the crack generation completely depends on the impact given during the grinding process [15]. After grinding, the state

获取价格

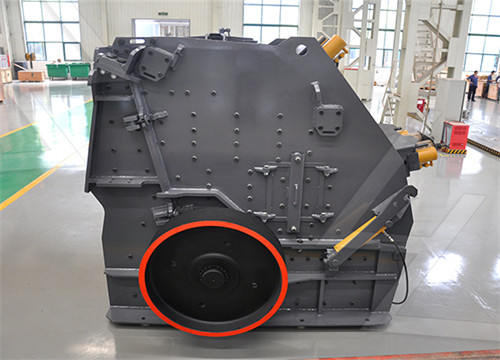

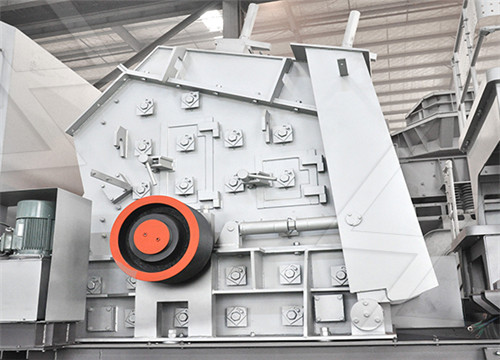

COAL GRINDING AND FIRING SYSTEMS - HAZOP ANALYSIS

A HAZOP study of a typical operating Coal Grinding and Firing System encompasses the following areas: a) Fuel handling and storage – Raw coal receiving, storage and handling. b) Fuel preparation – Raw coal grinding. c) Fuel conveying – Fine coal storage and conveying for an indirect firing system.

获取价格

How is pulverized coal processed? - sbmmill

2022年2月24日 Before pulverized coal grinding, the wet coal needs to be dried first, and then sent to the grinding chamber of the main engine continuously and evenly for grinding. The pulverized fine powder is classified by the classifier under the action of the air flow of the fan, and the fine powder of qualified fineness enters the collection stage ...

获取价格

An investigation of performance characteristics and energetic ...

2020年8月12日 grinding, it also includes the coal drying treatment, which is the thermal process, so attention should be paid to energy loss. The thermal balance equation considers the heat exchange

获取价格

of Coals in Mineral Processing Systems

During the grinding process, the existing pores create a new surface. Fractures propagate along the pores and cracks that appear between the phases. It is difficult to verify the reduction of energy due to complex energy balance in the grinding process. Due to a conversion of energy, coal is broken as primary energy is

获取价格

Energies Free Full-Text Technique to Investigate Pulverizing and ...

2021年11月4日 The total cost of crushing raw coal to the size of dust required by state-of-the-art coal-fired boilers consists of the cost of energy required for the crushing process in dust mills [2,3], the cost of energy required to overcome internal resistance in grinding plants, and the cost of replacing plant components used as a result of the high ...

获取价格

How is pulverized coal processed? - sbmmill

2022年2月24日 Production of clean pulverized coal for boiler combustion heating and power supply. Fineness: 200 mesh, D80-90, according to the needs of back-end combustion Suitable coal types: bituminous coal, anthracite, blue carbon, etc. The production of clean pulverized coal is used for boiler combustion heating and power supply to improve the

获取价格

An investigation of performance characteristics and

2020年8月12日 grinding, it also includes the coal drying treatment, which is the thermal process, so attention should be paid to energy loss. The thermal balance equation considers the heat exchange

获取价格

of Coals in Mineral Processing Systems

During the grinding process, the existing pores create a new surface. Fractures propagate along the pores and cracks that appear between the phases. It is difficult to verify the reduction of energy due to complex energy balance in the grinding process. Due to a conversion of energy, coal is broken as primary energy is

获取价格

Energies Free Full-Text Technique to Investigate Pulverizing and ...

2021年11月4日 The total cost of crushing raw coal to the size of dust required by state-of-the-art coal-fired boilers consists of the cost of energy required for the crushing process in dust mills [2,3], the cost of energy required to overcome internal resistance in grinding plants, and the cost of replacing plant components used as a result of the high ...

获取价格

Production of Ultra-Clean Coal by the Combined Method of

2022年12月19日 The long-flame coal used in the test was obtained from Inner Mongolia, China. The proximate analysis result of coal sample is presented in Table1. Table 1. Proximate analysis of coal sample (air dried). M ad (%) A ad (%) V ad (%) FC ad (%) 5.38 20.13 35.24 39.25 Due to the high content of raw coal ash, the density composition of

获取价格

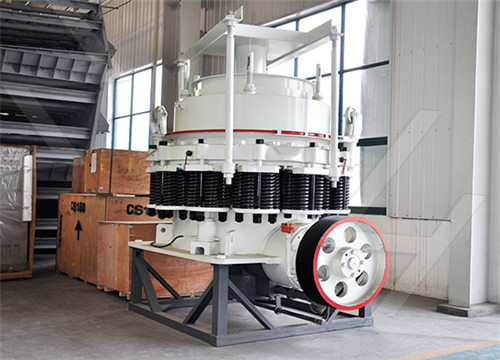

COAL GRINDING IMPS: more than meets the eye - Gebr.

achieved. The new coal grinding plant fully meets the expectations in terms of production capacity and operating values. General references in coal grinding More than 1000 MPS mills are being used worldwide for processing various types of coal, ranging from lignite to petcoke, including different kinds of hard coal and anthracite. Commissioning of

获取价格

11.10 Coal Cleaning - US EPA

11.10.1 Process Description1-2,9. Coal cleaning is a process by which impurities such as sulfur, ash, and rock are removed from coal to upgrade its value. Coal cleaning processes are categorized as either physical cleaning or chemical cleaning. Physical coal cleaning processes, the mechanical separation of coal from its contaminants using ...

获取价格

Grinding aids for dry fine grinding processes - ScienceDirect

2020年9月20日 1. Introduction. The history of grinding aids in dry fine grinding processes starts in the late 1930s with the application of the first commercial grinding aids in the cement industry [1].Since that time, the importance of grinding aids in industrial dry fine grinding processes has strongly increased; so did the number of scientific papers

获取价格

How to Process Coal into Pulverized Coal in 5 Steps?

2024年1月11日 The 5-step process to pulverize coal efficiently The coal pulverization process involves a precise sequence of steps. Each is systematically designed to convert raw coal into a fine, efficient powder. But you have to start by prepping up the coal rock before the grinding process. Step 1: Crush the coal rock The coal pulverization steps

获取价格

Effect of particle shape on the flotation kinetics of fine coking coal ...

2018年9月10日 Particle shape has a significant effect on the flotation process of fine mineral and fine coal particles. In this paper, the effects of particle shape on the flotation kinetics and behavior of fine coking coal of different size fractions were investigated. The coal particles with different shape properties were gained from the grinding and crushing

获取价格

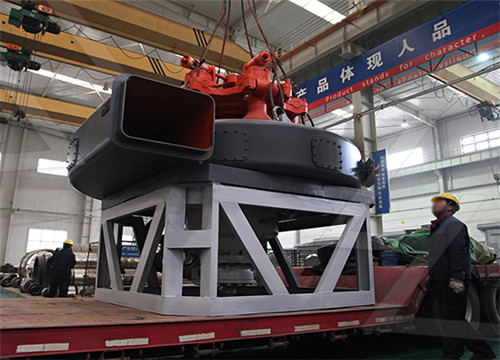

THE COAL GRINDING - energosteel

2017年7月11日 Coal grinding is preparatory process to a creating mixture for combustion in boilers at thermal power plants. To a high-quality fuel creation for the TPP units furnaces (fuel has the coal basis), needs to achieve the maximum material grinding degree and maximally reduce the coal dust moisture content. Fuel drying and fuel grinding can be ...

获取价格

ATTRITOR GRINDING MILLS AND NEW DEVELOPMENTS

additional ingredients can be added to the premix tank at any time during the grinding, and the processing can be terminated precisely. Fig. 3 Fig. 4 One advantage of the circulation system is that large quantities of material can be handled with a smaller investment of grinding media and Attritor equipment. Another advantage of the “Q”

获取价格

RARE EARTH ELEMENTS - National Energy Technology

Evaluation of Novel Strategies and Processes for Separation of REE from Coal -Related Materials ... leaching, and ion exchange; reactive grinding; photochemical, ultrasonic-assisted, microwave-aided, photophoretic, plasma, and supercritical CO 2 separation; and advanced sorbents and

获取价格

11.25 Clay Processing - US EPA

11.25.1 Process Description1-4. Clay is defined as a natural, earthy, fine-grained material, largely of a group of crystalline hydrous silicate minerals known as clay minerals. Clay minerals are composed mainly of silica, alumina, and water, but they may also contain appreciable quantities of iron, alkalies, and alkaline earths.

获取价格