bentonite processing mill

How to process bentonite and what is it used for? - sbmchina

2022年9月29日 Summary:In bentonite processing plant, grinding mill plays very important role. SBM can provide many types and models of grinding mills for customers

获取价格

Bentonite Mill - Grinding Mill - Suncomill

2020年10月21日 Bentonite Mill is ideal grinding machine to grind and process bentonite, and the fine powder size can be 40 mesh to 325 mesh for industry usage. The powder

获取价格

Process Development Essential to Bentonite Processing

While there are many variations on bentonite processing, testing is particularly important to two aspects: drying and agglomeration. Drying

获取价格

Bentonite Milling Machines

2024年1月12日 The choice of bentonite milling equipment depends on factors such as the desired particle size, production capacity, and the characteristics of the bentonite being

获取价格

Properties, Processing and Modification of Bentonite

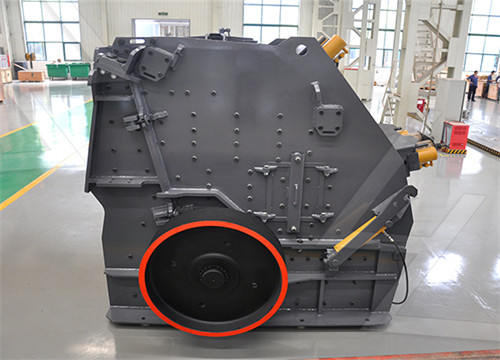

2022年4月1日 Bentonite grinding production line. The key production equipment used in the bentonite grinding production line are jaw crusher, impact crusher, Raymond mill,

获取价格

Types of Grinding Mills for Bentonite Processing Plant

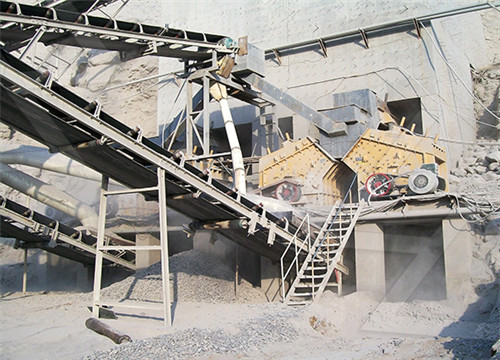

Bentonite processing involves several steps, including mining, drying, milling, and packaging. Here is a brief overview of the process: 1. Mining. Bentonite deposits are

获取价格

Bentonite Processing Plant, Bentonite Grinding Mill-SBM Industrial ...

Bentonite Processing Technology. 1.Sodium Modification Stage:Most of bentonite in the nature is calcium bentonite whose performance is worse than sodium bentonite.

获取价格

How much does the whole set of bentonite processing

2020年8月21日 For bentonite ore powder, Raymond mills, superfine mills, vertical mills and other equipment are all professional grinding processing equipment. Each mill has its own advantages and

获取价格

How to process bentonite and what is it used for? - sbmchina

2022年9月29日 Summary:In bentonite processing plant, grinding mill plays very important role. SBM can provide many types and models of grinding mills for customers to choose. What is Bentonite? Bentonite generally has a hardness of 1 to 2 (there are also relatively hard ones) and a density of 2 to 3g/cm3. It is a non-metallic mineral with

获取价格

11.25 Clay Processing - US EPA

Bentonite - A flow diagram for bentonite processing is provided in Figure 11.25-5. Mined bentonite first is transported to the processing plant and stockpiled. If the raw clay has a relatively high moisture content (30 to 35 percent), the stockpiled material may be plowed to facilitate air drying to a moisture content of 16 to 18 percent.

获取价格

Bentonite Processing Plant, Bentonite Mill

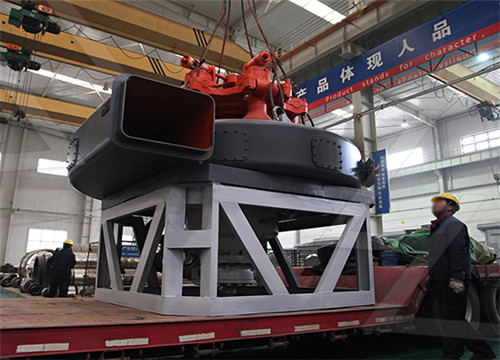

Grinding Processing. 1. Na-bentonite stage: In nature, the performance of calcium-based bentonite is worse than that of sodium-based bentonite. 2. Drying stage: Sodium-treated bentonite has higher moisture content and needs to be dried to a smaller moisture content. 3. Grinding stage: After drying, the bentonite is crushed, and the ore is lifted.

获取价格

cost of bentonite manufacturing processing plant - LinkedIn

2024年1月19日 Processing and Refining: The machinery plays a pivotal role in the processing and refining stages, ensuring the production of refined bentonite with superior properties.

获取价格

Raymond® Roller Mill air-swept vertical ring-roll - Schenck Process

The Raymond ® Roller Mill is an air-swept vertical ring-roll mill with an integral classification system that simultaneously dries, pulverizes and classifies a number of different types of products including limestone, clay, minerals and others. From a feed ranging in size from approximately. ½ -2in / 10-50mm, the roller mill can produce ...

获取价格

Bentonite Powder Processing Machine – HC Super Large Grinding Mill

HC super large bentonite powder grinding mill is designed for large-scale mineral powder production, Its technical parameter is at the domestic leading level. and is particularly suitable for large-scale powder processing in industries such as power plant desulfurization and manganese mining. This equipment featuring high production, high ...

获取价格

Professional Raymond Mill bentonite powder production line

Description. Professional Raymond Mill bentonite powder production line is widely used in the field of metallurgy, building materials, chemical industry and mining to process powder. It is used in grinding the non-flammable and non-explosive stuff which has the Moh’s hardness below 7, humidity less than 6%, such as gypsum, talc, calcite ...

获取价格

Processing drilling grade bentonite, which mill is better?

2018年3月16日 The market demand for drilling grade bentonite is increasing , the drilling grade bentonite processing grinding mill produced by Fujian Fengli has the following advantages: high output efficiency

获取价格

Bentonite Powder Processing Machine

What is Bentonite. Bentonite is a clay generated frequently from the alteration of volcanic ash, consisting predominantly of smectite minerals, usually montmorillonite. Other smectite group minerals include hectorite, saponite, beidelite and nontronite. Bentonite presents strong colloidal properties and its volume increases several times when ...

获取价格

Bentonite processing technology - ALPA Powder Equipment

2021年12月14日 Bentonite processing technology. Bentonite is a clay rock with montmorillonite as the main mineral component. It often contains a small amount of illite, kaolin, zeolite, feldspar, calcite and other minerals. Bentonite is a precious non-metallic mineral resource with more than 1,000 uses and is known as the “universal material”.

获取价格

Professional Supplier of Grinding Mills Solutions for Powder

MTW Trapezium Grinding Mill (Raymond Mill), LM vertical mill and other equipment can crush limestone, calcite, calcium carbonate, barite, gypsum, bentonite and other materials to 20-400 mesh.It is mainly used in pulverized coal equipment, heavy calcium processing, and other industries powder milling field.

获取价格

Bentonite Uses, Status and Processing in India - FTM Machinery

2020年3月14日 After being milled by Raymond mill, more than 95% of bentonite can reach 200 mesh, which can meet the requirements of general application fields. Skilled technical staff of Machinery can customize the bentonite processing plant combined with the suggestions of our senior engineers major research institutes

获取价格

How to process bentonite and what is it used for? - sbmchina

2022年9月29日 Bentonite processing equipment. In bentonite processing plant, grinding mill plays very important role. SBM can provide many types and models of grinding mills for customers to choose. Trapezium mill. Max. Input Size: 35mm. Min. Output Size: 0.038mm. Max. Capacity: 22t/h. Min. Power: 37Kw

获取价格

What micro powder grinding mill is needed for bentonite processing ...

For bentonite processing, what equipment is needed for the bentonite processing plant? Mill manufacturer Clirik can provide Raymond mill, micro powder grinding mill , ultra-fine vertical roller mill and other equipment to provide strong equipment protection for bentonite milling projects with different milling fineness and production capacity.

获取价格

Professional Supplier of Grinding Mills Solutions for Powder

MTW Trapezium Grinding Mill (Raymond Mill), LM vertical mill and other equipment can crush limestone, calcite, calcium carbonate, barite, gypsum, bentonite and other materials to 20-400 mesh.It is mainly used in pulverized coal equipment, heavy calcium processing, and other industries powder milling field.

获取价格

Bentonite Uses, Status and Processing in India - FTM

2020年3月14日 After being milled by Raymond mill, more than 95% of bentonite can reach 200 mesh, which can meet the requirements of general application fields. Skilled technical staff of Machinery can

获取价格

How to process bentonite and what is it used for? - sbmchina

2022年9月29日 Bentonite processing equipment. In bentonite processing plant, grinding mill plays very important role. SBM can provide many types and models of grinding mills for customers to choose. Trapezium mill. Max. Input Size: 35mm. Min. Output Size: 0.038mm. Max. Capacity: 22t/h. Min. Power: 37Kw

获取价格

What micro powder grinding mill is needed for bentonite processing ...

For bentonite processing, what equipment is needed for the bentonite processing plant? Mill manufacturer Clirik can provide Raymond mill, micro powder grinding mill , ultra-fine vertical roller mill and other equipment to provide strong equipment protection for bentonite milling projects with different milling fineness and production capacity.

获取价格

bentonite processing machinery manufacturers - Grinding Mill

»processing iron ore disadvantages that affect the environment and recycling »bentonite processing machinery manufacturers »foundation bolt forces in jaw crusher »gas balance of a ball mill »mobile crusher for sale south africa »small portable ball mill for sale »crushing wet sticky powder machine; Production Line Construction

获取价格

Bentonite Processing Equipment - hcmilling

Phase one: raw material crushing. Bentonite blocks will be crushed to 15mm-50mm fineness by crusher. Phase two: grinding. Crushed bentonite material will be sent to the storage hopper by the elevator, and than the feeder will send the material to the main mill for grinding. Phase three: classifying.

获取价格

Bentonite Processing Plant, Bentonite Grinding Mill-SBM

Bentonite Processing Technology. 1.Sodium Modification Stage:Most of bentonite in the nature is calcium bentonite whose performance is worse than sodium bentonite. 2.Drying Stage: After sodium modification, the bentonite has high moisture and must be dried to reduce the water content by dryer. 3.Grinding Stage:After drying, the bentonite would be

获取价格

Applications of Bentonite powder

As the main way to realize the value of bentonite---milling processing, it is bound to attract the attention of investment users. What equipment is used for grinding bentonite into powder? Usually, it uses the “crushing--milling” joint processing technology. The core equipment used in the equipment includes Raymond mill or ultra-fine mill.

获取价格

Chapter 5 Properties and Uses of Bentonite - ScienceDirect

1978年1月1日 According t o Olin et al. (1942), similar treatment of paper mill wastes, sewage, and industrial wastes by bentonite is satisfactory for their clarification. Water impedance Bentonite, particularly the sodium variety from Wyoming, is used extensively t o impede the movement of water through earthen structures and t o retard or stop similar ...

获取价格

Bentonite production process and equipment LZZG

Bentonite processing process The feeder sends the bulk bentonite to the jaw crusher for coarse crushing first, and the coarsely crushed bentonite material is sent to the impact crusher by the belt conveyor for medium and fine crushing. ... After the Raymond mill grinds the powder, the particle size is sorted by the classifier at the top of the ...

获取价格

Bentonite - m.sbm-mill

Bentonite is a clay rock, also known as montmorillonite clay rock, normally containing a small amount of illite, kaolin, halloysite, chlorite, zeolite, quartz, feldspar, calcite and the like; hardness 1-2, density 2~ 3g / cm3. ... SBM provides a range of grinding mills, including the MTM, MTW, LM, LUM, and SCM series. ... Bentonite Processing ...

获取价格

Roller Mill Bentonite Pulverising Mill - Crusher Mills

Bentonite Grinding Mill,Machine for Bentonite Powder Process Vertical roller mill for bentonite powder plant: vertical roller mill is mainly employed to grind the materials, mineral pulverising mills; cocoa processing plant;

获取价格

Bentonite - mill.zenith-mills

Bentonite is a non-metallic mineral with montmorillonite as its main mineral component and its content is 85-90%,the hardness is 1-2 and the density is 2-3g/m³,because of the change of iron content.there are different kinds of color,like White, light yellow, light grey, light green, pink, brown red, brick red, grey black etc..

获取价格

Bentonite Processing - Vertical grinding mill Price and Selection

The market has broad prospects for development. Bentonite manufacturers are also increasing. Different regions have different processing requirements for bentonite. What type of vertical grindingmill processing equipment is suitable for 100 mesh bentonite processing? Chaeng has more than 50 years of development history in the vertical mill.

获取价格