detail clinker crusher

Fine Jaw Crushers -

HSC550 Jaw Crusher – a proven trouble-free performer, this crusher reliably delivers consistent crushing results across materials including raw meal, clinker, cement, slag,

获取价格

进一步探索

Correct Rock Size for Jaw Crusher Feed What do Jaw Estimate Jaw Crusher Capacity - Mineral Processing JC2501 Jaw Crusher - Prolab SystemsJaw Crusher PDF Download - YUMPUProduct datasheet Essa® JC1250 Jaw Crusher -

Heavy-duty Roll Breaker Efficient clinker crushing with

The Heavy-duty Roll Breaker (HRB) is designed for optimum crushing eficiency and minimum wear, ensuring maximum cooler uptime and very low maintenance costs. No

获取价格

进一步探索

7 Hammer Crusher Common Problems And Solutions9 Hammer Crusher Common Faults and Solutions Fote

HRB MF clinker breaker -

An optimal crusher solution can help keep a kiln and cooler operating at peak eficiency. The HRB MF (heavy-duty roll breaker modular frame) sets the standard in clinker breakers

获取价格

进一步探索

HRB - Harris EquipmentHRB ROAD BLOCKER TECHNICAL SPECIFICATIONS

Clinker Cooler - Clinker Crusher - World Cement

Clinker Crusher Unit. Clinker roller crushers are designed for crushing the clinker coming from end of the cooler. The equipment named as Roller Crusher consist of the housing, several rollers located inside the body,

获取价格

What Are The Cement Clinker Crushing Equipment ... - Eastman Rock Crusher

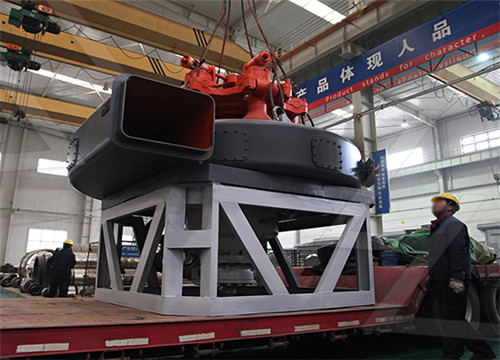

2022年1月22日 Cone crusher is advanced crushing equipment in the mining field. Its outstanding advantages are a high degree of automation, wide particle size adjustment range, and stable operation. In the process of cement clinker processing, a high degree of automation means that the operation process and steps of the equipment can be further

获取价格

M/s Ultratech Cement Limited (UTCL) 1.1 DETAILS OF THE

1.1 DETAILS OF THE PROJECT Table - 1 S. No. PARTICULARS DETAILS 1. Nature Size of the Project Proposed Integrated Cement Project (3.5 MTPA of Clinker, 5.0 MTPA of Cement, 50 MW of CPP and 1.0 MTPA Coal Washery) 2. Location Village Sarkipar, Piprahi Simradhi Tehsil Baloda Bazar District Baloda Bazar State Chhattisgarh

获取价格

Cement Manufacturing Process: 6 StepsTo Make

2020年1月27日 6 steps of the cement manufacturing process. When we talked about the manufacturing of cement, anyone who knows the cement manufacturing process slightly will mention “two grinding and one

获取价格

Heavy-duty Roll Breaker -

When clinker boulders get stuck in your crusher, you have no option but to shut down the cooler while you clear the blockage. Costs go up, productivity goes down. It doesn’t have to be this way. The Heavy-duty Roll Breaker crushes through the biggest boulders with ease. No more blockages, no more lost productivity.

获取价格

TerraSource Clinker Crushers by Pennsylvania Crusher

Features. Our unique design represents a major improvement in technology and offers the following unique advantages over ordinary clinker grinders. Pennsylvania Crusher clinker crushers are available as direct replacements for nearly every make and model of crusher. They can be interchanged with no fit-up problems or delays.

获取价格

Clinker Crushers Industrial Process Furnaces Ovens

Pennsylvania Crusher clinker crushers are available as direct replacements for nearly every make and model of crusher. They can be interchanged with no fit-up problems or delays. We've equipped the rolls with a special tooth pattern that has a greater number of crushing points - up to 18 tooth presentations per revolution!

获取价格

Clinker Cooler - Clinker Crusher - World Cement Market - FONS

Clinker Crusher Unit. ... DETAIL . CLINKER CRUSHER UNIT. Clinker roller crushers are designed for crushing the clinker coming from end of the cooler... DETAIL . INDUSTRIAL PRODUCTS. The product groups of parts of washing machines used in washing plants with a cycle of liquid spray...

获取价格

2 Major Roles of Limestone in Cement Manufacturing

2023年5月27日 The answer is the cement industry. Limestone plays two major roles in the cement manufacturing process, one is used as a raw material for cement clinker, and the other is used as a cement admixture. Limestone is one of the key raw materials of cement clinker. Around 80-90% of the raw material for the kiln feed is limestone.

获取价格

Clinker Crusher at best price in Baramati by Precitech Engineers ...

Get Clinker Crusher in Baramati, Maharashtra at best price by Precitech Engineers/Universal Industries. Also find Roll Crusher price list from verified suppliers with contact number ID: 3565927655 ... Seller Contact Details. Precitech Engineers/Universal Industries. Rajesh Sonar. MIDC,PLOT NO. C.89 MIDC, MIDC, BARAMATI,

获取价格

Cement Production Process - AGICO

2020年8月25日 Clinker production: The diameter of the clinker ball must between 0.32 and 5.0cm. There are three steps of the high-temperature system: Drying or preheating, calcining, and sintering. The calcining is the core part of the clinker production; the raw meal is weighed and sent into preheater and cement kiln to process clinker. Grate cooler helps

获取价格

Jaw Crushers - high quality and reliability from RETSCH

Retsch. Products. Milling. Jaw Crushers. The RETSCH Jaw Crusher range is used for the rapid, powerful crushing and pre-crushing of mediumhard, hard, brittle and tough materials. The variety of materials offered, their efficiency and safety make them ideal for sample preparation in laboratories and industrial plants. Benchtop Unit.

获取价格

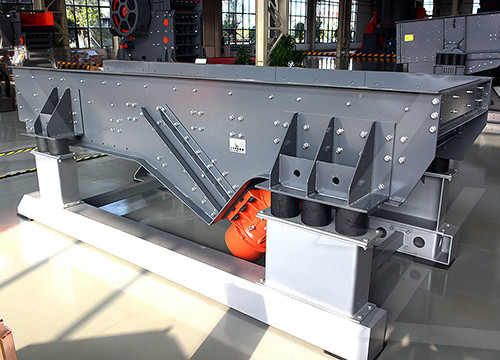

Crusher dalmachinery

Due to that, we are manufacturing clinker crusher with different capacities, High quality workmanship down to last detail ensure optimum operating costs to : Tailor-made design and manufacturing ; High availability and reliability of minimizing operational costs; Long wear life ; Easy maintenance and operation ; Low power consumption

获取价格

Roll crusher for crushing hot cement clinker - Google Patents

2010年6月10日 The aim of the invention is to provide a roll crusher for a grate cooler for cooling hot bulk material, in particular hot cement clinker, comprising several parallel crusher rolls. Said rolls are driven in opposite directions and comprise respective rotatably mounted axle tube rolls, onto each of which a large number of crusher rings (10) that can

获取价格

Grate Cooler - INFINITY FOR CEMENT EQUIPMENT

Grate Cooler. 1. Introduction. Clinker Cooling is an Important phase in clinker production. Clinker Cooler is exposed to extremely difficult operating-conditions with a highly abrasive and hot material. The Cooling Rate of clinker at elevated temp. has direct impact on cement strength (fig.1). cooling and grindability of clinker.

获取价格

Jaw Crushers - high quality and reliability from RETSCH

Retsch. Products. Milling. Jaw Crushers. The RETSCH Jaw Crusher range is used for the rapid, powerful crushing and pre-crushing of mediumhard, hard, brittle and tough materials. The variety of materials offered, their efficiency and safety make them ideal for sample preparation in laboratories and industrial plants. Benchtop Unit.

获取价格

Crusher dalmachinery

Due to that, we are manufacturing clinker crusher with different capacities, High quality workmanship down to last detail ensure optimum operating costs to : Tailor-made design and manufacturing ; High availability and

获取价格

Roll crusher for crushing hot cement clinker - Google Patents

2010年6月10日 The aim of the invention is to provide a roll crusher for a grate cooler for cooling hot bulk material, in particular hot cement clinker, comprising several parallel crusher rolls. Said rolls are driven in opposite directions and comprise respective rotatably mounted axle tube rolls, onto each of which a large number of crusher rings (10) that can

获取价格

Grate Cooler - INFINITY FOR CEMENT EQUIPMENT

Grate Cooler. 1. Introduction. Clinker Cooling is an Important phase in clinker production. Clinker Cooler is exposed to extremely difficult operating-conditions with a highly abrasive and hot material. The Cooling Rate of clinker at elevated temp. has direct impact on cement strength (fig.1). cooling and grindability of clinker.

获取价格

BASIC CEMENT PLANT LAYOUT - The Cement Institute

2020年2月3日 There are mainly two types of crushers available for this purpose- compression type or impact type crushers. There are many types of compression type crushers such as jaw crusher, gyratory crusher, cone crusher, roll crusher. ... 11/12 Clinker/Gypsum Storage . The output of the kiln is stored before it is fed to the cement

获取价格

Roll Crusher for Crushing Hot Cement Clinker - Google Patents

The aim of the invention is to provide a roll crusher for a grate cooler for cooling hot bulk material, in particular hot cement clinker, comprising several parallel crusher rolls. Said rolls are driven in opposite directions and comprise respective rotatably mounted axle tube rolls, onto each of which a large number of crusher rings that can be connected to the

获取价格

配置中置辊式破碎机的第四代篦冷机的工艺设计

2021年11月25日 Process Design of Fourth Generation Clinker Cooler With Middle Roller Crusher: Tianjin Cement Industry Design Research Institute Co., Ltd. ... This article comprehensively introduced the design details of technical transformation process from the 3rd generation cooler to the 4th generation cooler, including selection principle of the first ...

获取价格

Cement Euipment Overview Cement Making Machines Cement

2019年9月27日 There are various types of cement crusher on the market, including jaw crusher, cone crusher, hammer crusher, impact crusher, and etc. AGICO Cement can provide all types of cement crusher. Our cement crusher can fully crush the raw material, reduce feed size into the mill, and increase the reaction of raw material in the following

获取价格

Used Crushers for Sale Mining Surplus Record

USA and Canada's #1 source for used and surplus crushers for the mining and minerals. All types available and in stock from mining equipment dealers near you. ... View Details Contact Seller $12,650 Make Offer. Expand. 4 Photos. ... crusher single roll clinker. JM Industrial LLC Millwood, WV. 304-27... (Show) 304-273-0795. Category: Crushers.

获取价格

Pyrofloor²® - KHD Humboldt Wedag

The cooler is the last step in the clinker production process. Last, but not least. The cooler has a vital role in ensuring the final quality of the clinker and enhancing process efficiency by recuperating process heat to the kiln. Not to mention the job that gives it its name: cooling the clinker before it’s milled. Improving cooler performance therefore has benefits well

获取价格

Roller Press - KHD Humboldt Wedag

Simply put, the roller press is the most energy-efficient grinding machine on the market. Since its commercial introduction into the cement industry by KHD in the 1980s, hundreds of them have been installed in the cement and minerals industries, in both finish and semi-finish applications. And with the lowest specific energy consumption among comparable

获取价格

Vertical Shaft Impact Crusher - AF Minerals Equipment

The GS series crusher’s bearing seat uses a thin oil lubrication system. Its highest rotor speed is clocked at 82m/s, greatly improving the capacity of the equipment and processing efficiency. In addition, VSI and GS series crushers have been designed to minimize maintenance and improve all the adjustment operations.

获取价格

White cement cooler > Cooling > Clinker production > Cement

The clinker discharged from the rotary kiln enters the rotary cooler and is rapidly quenched with water from 1,400°C to 600°C. The clinker subsequently passes through the roll crusher, which produces grain sizes < 50 mm. Finish cooling from 600°C to the ultimate temperature of approx. 100°C is performed on the vibrating grate with air.

获取价格

Clinker crushing diesel rock hummer mill crusher machining

Clinker crushing diesel rock hummer mill crusher machining China factory direct supply glass metal shredder machine crusher stone machine is suitable for crushing minerals of various brittle materials, such as coal, gypsum, alum, brick, limestone, etc.The compressive strength of the material shall not exceed 1000 kg force/cm 2 and the humidity ...

获取价格