rotary dryew for chromium or chromite ore

Technology Innovations in the Smelting of Chromite Ore

pelletized chromite ores in a rotary kiln using energy obtained from coal pulverization and hot gases generated from the closed submerged arc furnace. It also provides high

获取价格

Enhanced Chromium Recovery in the Smelting of Ferronickel

2021年11月19日 In the laterite nickel ore, the chromium usually exists in the form of chromium trioxide. The initial temperature required for reduction of chromium trioxide to

获取价格

Surface Technology Environmental Resource Center - STERC

Grinding and Roasting. The chromic acid manufacturing process is essentially the conversion of chromite ore to sodium chromate solution, to bichromate of soda crystals,

获取价格

11.5 Refractory Manufacturing - US EPA

Chromium compounds are emitted from the ore crushing, grinding, material drying and storage, and brick firing and finishing processes used in producing these types of

获取价格

Technology Innovations in the Smelting of Chromite Ore

pelletized chromite ores in a rotary kiln using energy obtained from coal pulverization and hot gases generated from the closed submerged arc furnace. It also provides high recoveries of ferrochrome and utilizes low cost reductant sources such as anthracite. Keywords: Chromite ore, Ferrochrome, Submerged arc furnace, Outokumpo, Premuse 1.

获取价格

Chromium Compounds - U.S. Environmental Protection Agency

Air emissions of chromium are predominantly of trivalent chromium, and in the form of small particles or aerosols. (1,2) The most important industrial sources of chromium in the atmosphere are those related to ferrochrome production. Ore refining, chemical and refractory processing, cement-producing plants, automobile brake

获取价格

Chrome Ore Process Plant - JXSC Mineral

Chrome magnetic separation How determine the chrome ore concentrating method and select the right chrome mining equipment is closely related to the physical and chemical properties of chromium ore. Because chromite is weakly magnetic, with the development of high-intensity magnetic separation technology, the technology of purifying chromium

获取价格

How to process Chrome ore with Mining equipment?

The selection of chrome ore mining equipment is closely related to the physical and chemical properties of chromium ore. Because chromite is weakly magnetic, with the continuous improvement of high intensity magnetic separation technology, the technology of purifying chromium ore with high intensity magnetic separation has been very mature.

获取价格

Green Battery Minerals How to Get Lithium from Spodumene

2023年4月7日 After the screening, qualified spodumene minerals are fed into the grinding and grading process. The particle size of spodumene ore is ground to less than 0.15 mm to obtain a better flotation effect. Spodumene grinding equipment you need. Wet-type ball mill: The ore under the sieve is sent to the wet-type grid ball mill for grinding. (Minimum ...

获取价格

Chromium and dolomite removal from rotary filter cake in

The Acknowledgement chromite ore (FeCr20.J for chrome chemical industry, the This work was supported by The Chrome Chemical In- ratio of Cr : Fe in the ore, less than 2 : 1, is more suitable. dustry in Iran. Chromium was extracted from its ores by dissolving in an alkaline or acidic solution.

获取价格

Pre-Drying of Chlorine–Organic-Contaminated Soil in a Rotary Dryer

2022年12月10日 In response to the current problem of the high energy consumption of direct thermal desorption systems when treating soils with a high moisture content, we propose using the waste heat of the system to pre-dry soil to reduce its moisture. Taking chlorine–organic-contaminated soil as an object, an experimental study on the drying and

获取价格

Minerals Free Full-Text An Overview of Currently Applied ...

2023年6月13日 Ferrochrome (FeCr) is the main source of virgin chromium (Cr) units used in modern-day chromium (Cr) containing alloys. The vast majority of produced Cr is used during the production of stainless steel, which owes its corrosion resistance mainly to the presence of Cr. In turn, stainless steel is mainly produced from Cr-containing scrap metal

获取价格

40 CFR Part 63 Subpart NNNNNN - eCFR :: Home

Chromite ore means an oxide of chromium and iron (FeCr 2 O 4) that is the primary feedstock for chromium compounds manufacturing. Chromic oxide means Cr 2 O 3 . In the production of chromic oxide, ammonium sulfate and sodium dichromate that have been concentrated by evaporation are mixed and fed to a rotary roasting kiln to produce

获取价格

Chromium and dolomite removal from rotary filter cake in

insoluble mud was retained by rotary drum filter. The solu tion containing hexavalent Cr was reduced to sodium dichromate using sulfur dioxide as reducing agent. The crystallized dichromate was converted to chromium oxides (Cr20 3 and Cr03). In the process of extraction of chromium compounds from chrome ore, the filter cake was analyzed

获取价格

Rotary Dryer Design Working Principle - 911 Metallurgist

2016年6月1日 Rotary driers have thermal efficiencies of from 50 to 75 per cent on ores. This must be taken into account when using the above table, which is figured at 100 per cent. The drier shell is rotated separately from the stationary kiln section. To achieve the rotation a BULL GEAR is attached around the shell section.

获取价格

The Soda-Ash Roasting of Chromite Minerals: Kinetics

2000年9月5日 The composition and mineralogical characteristics of the lyzed to determine the percentage extraction of chromium chromite ore influence the kinetics of the roasting process. as sodium chromate. One gram of roasted sample was The properties of chromite ores vary significantly between leached in the boiling water for 15 minutes and filtered. The

获取价格

Chromium processing Extraction, Uses Applications

2024年1月5日 chromium processing, preparation of the ore for use in various products. Chromium (Cr) is a brilliant, hard, refractory metal that melts at 1,857 °C (3,375 °F) and boils at 2,672 °C (4,842 °F). In the pure state it is resistant to ordinary corrosion, resulting in its application as an electroplated protective coating for other metals.

获取价格

Mineral Drying - FEECO International Inc.

Mineral Drying. Drying is a critical aspect of mineral processing; throughout the journey from ore to end product, the ability to control moisture content helps to reduce shipping costs, streamline downstream processing, and produce a refined product. While mineral dryers may appear the same as other industrial dryers, they are typically built ...

获取价格

Rotary Dryer Design Working Principle - 911 Metallurgist

2016年6月1日 Rotary driers have thermal efficiencies of from 50 to 75 per cent on ores. This must be taken into account when using the above table, which is figured at 100 per cent. The drier shell is rotated separately from the stationary kiln section. To achieve the rotation a BULL GEAR is attached around the shell section.

获取价格

The Soda-Ash Roasting of Chromite Minerals: Kinetics

2000年9月5日 The composition and mineralogical characteristics of the lyzed to determine the percentage extraction of chromium chromite ore influence the kinetics of the roasting process. as sodium chromate. One gram of roasted sample was The properties of chromite ores vary significantly between leached in the boiling water for 15 minutes and filtered. The

获取价格

Chromium processing Extraction, Uses Applications

2024年1月5日 chromium processing, preparation of the ore for use in various products. Chromium (Cr) is a brilliant, hard, refractory metal that melts at 1,857 °C (3,375 °F) and boils at 2,672 °C (4,842 °F). In the pure state it is resistant to ordinary corrosion, resulting in its application as an electroplated protective coating for other metals.

获取价格

Mineral Drying - FEECO International Inc.

Mineral Drying. Drying is a critical aspect of mineral processing; throughout the journey from ore to end product, the ability to control moisture content helps to reduce shipping costs, streamline downstream processing, and produce a refined product. While mineral dryers may appear the same as other industrial dryers, they are typically built ...

获取价格

Chrome Ore Manufacturers, Suppliers, Exporters, Companies

Main Products: Chrome Ore, Chromium Ore, Chromite Sand ; Recommended For you. 3-200TPH Chrome Ore Concentrate Rotary Dryer. Chromium Oxide (Cr2O3) Chrome Ore. chromite ore, Chrome Ore. Chrome Ore chromite sand supplier ladle filler sand/ ore AFS30-35 chromite sand/ chrome. Get Latest Price;

获取价格

Chrome Processing Plant, Equipment - JXSC Machinery

Chrome has strong siderophilicity, and ferrochrome is often associated, also called chromite.Chrome ore beneficiation aims to extract chromium minerals from raw ore and remove impurities to obtain high-quality chrome concentrate. Generally speaking, chrome ore contains a certain amount of iron, so gravity separation and magnetic separation

获取价格

Exploring Chromium Ore Consumption: New Perspectives

chromium ore is chromite (Ministry of Natural Re-sources of P. R. China, 2021a, 2021b) (Supplemen-1Institute of Mineral Resources, Chinese Academy of Geological Sciences, Beijing 100037, China. 2To whom correspondence should be addressed; e-mail: 1264124110@qq 929

获取价格

Briquetted chrome ore fines utilisation in ferrochrome production at ...

2004年1月1日 In the comparative study in identical condition, the chromite sinter showed much better metallic yield (76%) and higher chromium content (54.6%) in the produced ferrochrome than the lump ore (70 ...

获取价格

Chromite - Wikipedia

Chromite is a crystalline mineral composed primarily of iron(II) oxide and chromium(III) oxide compounds. It can be represented by the chemical formula of FeCr 2 O 4.It is an oxide mineral belonging to the spinel group.The element magnesium can substitute for iron in variable amounts as it forms a solid solution with magnesiochromite (MgCr 2 O 4). A

获取价格

Preparation of Oxidized Pellets with Chrome Ore SpringerLink

2018年1月19日 The chemical compositions of chromite ore and bentonite are listed in Table 1, from which, it ` chromite concentrate contains 41.84% Cr 2 O 3 and a low Cr 2 O 3 /FeO ratio of 2.1, the impurities like Al 2 O 3 and MgO are above 15%, but the content of SiO 2, TiO 2, V 2 O 5 are very low. X-ray diffraction analysis of chromite ore was carried out.

获取价格

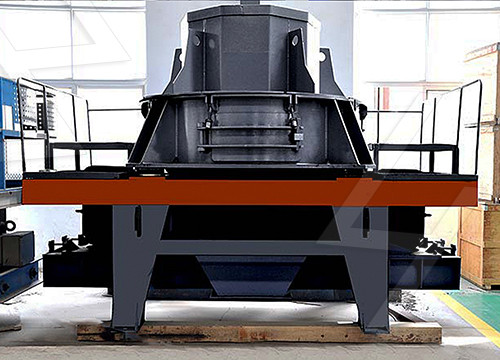

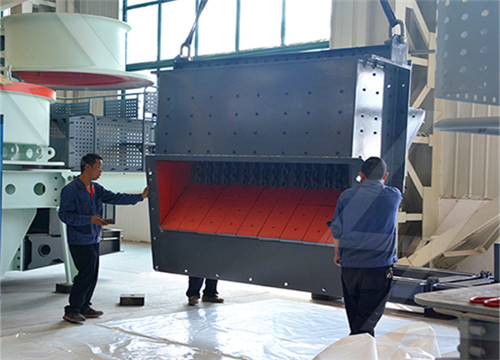

Hammer Crusher Industry Hammer Mills - JXSC Machine

A hammer mill, like a hammer crusher, or hammer breaker, can crush the 600-1800mm materials to below 25 or 25 mm. Sometimes, the application fields name the hammer mill crusher, such as coal crusher, coke crusher, limestone hammer crusher, brick crusher, cement hammer crusher, etc. 【 Our Hammer Crusher Types 】Single rotor and

获取价格

Chromite: The only mineral ore of chromium metal - Geology

Chromite is an oxide mineral composed of chromium, iron, and oxygen (FeCr 2 O 4 ). It is dark gray to black in color with a metallic to submetallic luster and a high specific gravity. It occurs in basic and ultrabasic igneous rocks and in the metamorphic and sedimentary rocks that are produced when chromite-bearing rocks are altered by heat or ...

获取价格

Formation Of Sodium Chromate From Chromite Ore

: Chromite ore concentrate was dried and ground in lab scale grinding mill to about 100 % (200 mesh) then was sampled into batches of 500 g each in preparation for briquetting experiments.

获取价格

Understanding Rotary Dryers: Types, Applications, and Maintenance

2023年8月2日 Rotary dryers play a crucial role in the biomass and waste management industries. They are used to dry biomass, such as wood chips, sawdust, and agricultural residues, for use as fuel or feedstock. Additionally, rotary dryers are employed in the drying of waste materials, such as sewage sludge and industrial by-products, before disposal or ...

获取价格