sag mill fl filetype

A Hybrid Intelligent Framework for Maximising SAG Mill

1. Introduction3.1. Outlier detection and feature selection methods3.2.2. Tree-based models3.3.2. Genetic Algorithms (GAs)3.4. The proposed framework4. Experimental results4.1. Machine learning prediction results4.3. Optimisation resultsThe process of separating valuable minerals from waste materials in mineral processing plants involves a series of intricate procedures. These procedures can be categorised generally into crushing, grinding, and concentration. Grinding is one of the most important procedures, where unconnected media such as balls, rods, or pebbles are utilised for ...

Integrated advanced process control with a sag mill monitor

(EGL) SAG mill driven by a 24,000 kW gearless drive. The SAG mill feeds two ball mills each 26 ft. in diameter × 40 ft. long (EGL), each driven by a 16,400 kW drive.

获取价格

Choosing a SAG Mill To Achieve Design Performance

2021年1月11日 the correct power required to grind ore in a SAG mill, by developing ore hardness variability functions for the ore body to be mined. This paper describes the next

获取价格

Operation Analysis of a SAG Mill under Different Conditions

In order to obtain the optimal operation parameters of a SAG mill, in this paper, the discrete element method (DEM) is used to simulate the breakage process of the particles by

获取价格

Operation Analysis of a SAG Mill under Different Conditions

energies Article Operation Analysis of a SAG Mill under Di erent Conditions Based on DEM and Breakage Energy Method Qiyue Xie 1, Caifengyao Zhong 2, Daifei Liu 1,*, Qiang Fu

获取价格

SAG Mill Optimization using Model Predictive Control - Andritz

MODEL PREDICTIVE CONTROL OF SAG WEIGHT. The MPC controller was installed to control the SAG mill weight, the belt weight in the ore feed system, and the SAG mill

获取价格

Application Note SAG Mill Control - mipac.au

stabilise SAG mill load and density by manipulating variables such as feed-rate, mill speed and feed water. You thereby improve efficiency without purchasing new control software

获取价格

Semi-autogenous grinding (SAG) mill liner design and

Traditionally, the number of shell lifters used in a SAG mill is equal to twice the number of the feet in the mill shell diameter (e.g., a 34-ft-diameter mill shell would have 68 shell

获取价格

MILLING CURVES AS A TOOL FOR CHARACTERISING SAG

Table 1 Specifications of the South Deep SAG Mill Diameter (int), m 7.80 Cone angle, o 15.0 Open Area, % 7.3 Length (belly), m 4.35 Trun Diam (D), m 1.54 Ball size, mm 100

获取价格

SAG Mill Liner Design - 911 Metallurgist

2016年6月6日 Based on experience, mill-liner designs have moved toward more open-shell lifter spacing, increased pulp lifter volumetric capacity, and a grate design to facilitate maximizing both pebble-crushing circuit

获取价格

SAG mill increases productivity, reduces unscheduled

to protect SAG mill liner bolts from extreme environmental conditions, including high temperatures and harsh vibrations. With the help of Mining Products and Service (MPS) – an Australia-based company specializing in the design, supply and optimization of wear components for the mining industry – Relining Minerals launched studies to

获取价格

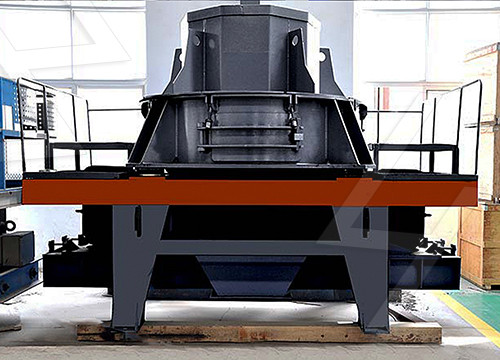

Understanding the SAG Mill in Copper Ore Mining Process

A SAG mill, or semi-autogenous grinding mill, is a type of machine used in mining and mineral processing operations. It uses the crushing and grinding action of rocks to reduce materials such as copper ore into smaller pieces for further processing. Unlike traditional mills that rely on steel balls or other media to break down materials, SAG ...

获取价格

SAG Mill Testing - Test Procedures to Characterize Ore

The SAGDesign test was developed by the SAGDesign Consulting Group (Starkey, Hindstrom Nadasdy, 2006) and consists of a batch grinding test conducted in a 0.488m diameter SAG mill. About 10kg of drill core is required for testing. The feed is prepared to 80% passing 19mm and ground to 80% passing 1.7mm.

获取价格

sag mill fl filetype pdf

UNUSED FL 36' x 24' (11m x 7.3m) Dual Pinion SAG Mill with 2 ABB 9,000 kW (12,069 HP) Motors for Total Power of 18,000 kW (24,138 HP) Lumwana SAG Mill Commissioning Commences - Kitco by the ABJV, FL Schmidt and Siemens.

获取价格

CONGA: THE WORLD’S FIRST 42 FOOT DIAMETER 28 MW

that a slightly more expensive 42 ft SAG mill with equivalent power to the 40 ft SAG mill enhanced the project economics. After assessing the potential reliability difference between the 40 ft SAG mill and the equivalently powered 42 ft SAG mill, Newmont made the decision in 2010 to purchase a 42 ft SAG mill from Metso and a 28 MW GMD from ABB ...

获取价格

Whitepaper Mill Optimisation

SAG mill circuit No. of mills # 1 SAG mill motor power installed kW 28,000 Motor type Gearless Mill manufacture SAG mill dimensions diameter length 40 ft (12,192 m) 26 ft (7,924 m) Mill direction Bi-directional Mill speed – range % critical 0-80 Mill speed – nominal % critical 76 SAG mill specific energy kWh/t 6.6 Grinding media Mm 125

获取价格

(PDF) Operation Analysis of a SAG Mill under Different

2020年10月9日 Simulation results under the ∅5250 × 500 mm mill model show that the mill operates with the optimal effect when the mill is under the condition of 80% critical speed and 15% fill level; the ...

获取价格

SAG Mill - Official Feed The Beast Wiki

The SAG Mill is a machine added by Ender IO. It uses Micro Infinity (µI) to grind (or mill) items into their crushed variants, like Ores into Dusts. The SAG Mill has four output slots; recipes can have 1-4 different outputs, with different chances of obtaining those outputs. Uniquely, the SAG Mill can use Grinding Balls made from various materials to increase

获取价格

What’s the Difference Between Ball Mill, Rod Mill and SAG Mill?

2020年3月20日 Ball mill: Ball mills are the most widely used one. Rod mill: The rod mill has the highest efficiency when the feed size is <30mm and the discharge size is about 3mm with uniform particle size and light overcrushing phenomenon. SAG mill: When the weight of the SAG mill is more than 75%, the output is high and the energy consumption

获取价格

sag mill fl filetype pdf

sag mill fl filetype pdf - csdpmap. The Fimiston SAG mill alone uses 12 megawatts of power FL to deliver gold processing plant to Russian customer. limestone mill filetype pdf. Read More. Get Price And Support Online; Grinder Machine Filetype Pdf -

获取价格

Operation Analysis of a SAG Mill under Different Conditions

energies Article Operation Analysis of a SAG Mill under Di erent Conditions Based on DEM and Breakage Energy Method Qiyue Xie 1, Caifengyao Zhong 2, Daifei Liu 1,*, Qiang Fu 1, Xiaoli Wang 3 and Zhongli Shen 1 1 School of Electrical Information Engineering, Changsha University of Science Technology, Changsha 410114, China;

获取价格

ITP Mining: Improving Energy Efficiency in SAG Mills

Improving Energy Efficiency in SAG Mills. Pilot-Scale SAG Mill Facility Will Help to Optimize Charge Motion and Slurry Flow in Plant-Scale SAG Mills - Reducing Energy Consumption. The U.S. mining industry operates approximately 80 semi-autogenous grinding mills (SAG) throughout the United States. Both mine and mill site variables determine SAG ...

获取价格

A Comprehensive Guide to SAG Mill Operation - ball mills supplier

Working Principle of a SAG Mill. The rock and grinding media are placed in the mill and rotated, causing the grinding media to tumble and crush the rock into smaller pieces. The mill operates in a closed circuit with screens that size the ore and send it back to the mill for further grinding. The product from the mill is then sent to a cyclone ...

获取价格

sag mill fl filetype pdf

sag mill fl filetype pdf - csdpmap. The Fimiston SAG mill alone uses 12 megawatts of power FL to deliver gold processing plant to Russian customer. limestone mill filetype pdf. Read More. Get Price And Support Online; Grinder Machine Filetype Pdf -

获取价格

Operation Analysis of a SAG Mill under Different Conditions

energies Article Operation Analysis of a SAG Mill under Di erent Conditions Based on DEM and Breakage Energy Method Qiyue Xie 1, Caifengyao Zhong 2, Daifei Liu 1,*, Qiang Fu 1, Xiaoli Wang 3 and Zhongli Shen 1 1 School of Electrical Information Engineering, Changsha University of Science Technology, Changsha 410114, China;

获取价格

ITP Mining: Improving Energy Efficiency in SAG Mills

Improving Energy Efficiency in SAG Mills. Pilot-Scale SAG Mill Facility Will Help to Optimize Charge Motion and Slurry Flow in Plant-Scale SAG Mills - Reducing Energy Consumption. The U.S. mining industry operates approximately 80 semi-autogenous grinding mills (SAG) throughout the United States. Both mine and mill site variables determine SAG ...

获取价格

A Comprehensive Guide to SAG Mill Operation - ball mills supplier

Working Principle of a SAG Mill. The rock and grinding media are placed in the mill and rotated, causing the grinding media to tumble and crush the rock into smaller pieces. The mill operates in a closed circuit with screens that size the ore and send it back to the mill for further grinding. The product from the mill is then sent to a cyclone ...

获取价格

sag mill fl filetype - sek-stolarstwo

sag mill fl filetype pdf. SAG mill and two 26 ft ball mills, all made by . The drive systems that enable the mills to operate at benchmark levels of reliability, efficiency and availability were made by ABB, whose solution comprises a 23.5 MW gearless mill drive (GMD) for the SAG mill, and two 13 MW low-speed dual-pinion ring-geared mill drive (RMD) systems

获取价格

Mill (grinding) - Wikipedia

Principle of SAG Mill operation SAG mill. SAG is an acronym for semi-autogenous grinding. SAG mills are autogenous mills that also use grinding balls like a ball mill. A SAG mill is usually a primary or first stage grinder. SAG mills use a ball charge of 8 to 21%. The largest SAG mill is 42' (12.8m) in diameter, powered by a 28 MW (38,000 HP ...

获取价格

MILLING CURVES AS A TOOL FOR CHARACTERISING SAG

Table 1 Specifications of the South Deep SAG Mill Diameter (int), m 7.80 Cone angle, o 15.0 Open Area, % 7.3 Length (belly), m 4.35 Trun Diam (D), m 1.54 Ball size, mm 100

获取价格

Pre-Processing to Increase the Capacity of SAG Mill Circuits

2022年6月6日 Simulations indicated that a capacity increase of 12% would be achieved in the existing grinding circuit by further crushing 35% of SAG mill fresh feed. Such figures would represent yearly additions of 8.3 kt in copper and 250 kg in gold productions. Study. Minerals 2022, 12, 727.

获取价格

Ball Mill vs SAG Mill: What’s the Difference?

Ball Mills have a higher degree of efficiency than SAG Mills due to their smaller size and have more area for grinding particles, leading to faster grinding. On the other hand, SAG Mills have a larger and deeper drum that provides larger lifting force which increases grinding efficiency. In addition, due to its larger size, SAG Mills consumes ...

获取价格

Minding the Grind: Maintenance Options to Keep SAG Mills

Given the impact that SAG mill performance has on overall plant performance, operators also have to pay attention to the design and construction of ancillary equipment, such as trommels, to avoid stoppages or loss of throughput from breakage, unexpected wear or loss of processing capacity. ... FL 32224 USA +1 904 721 2925 subscriptions@mining ...

获取价格

(PDF) Multi-component AG/SAG mill model - ResearchGate

2013年4月1日 Abstract and Figures. The JKMRC has been studying and modelling industrial AG and SAG mills for over 40 years, but the ability to simulate the effects of blending hard and soft components on mill ...

获取价格

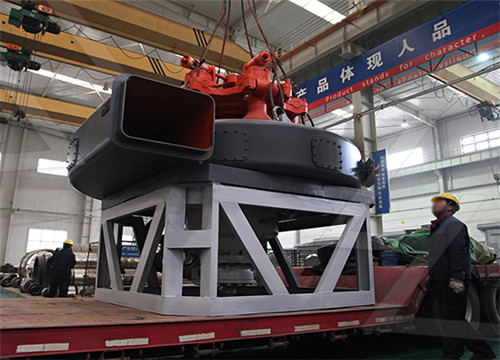

SAG Mill Components - 911 Metallurgist

2018年4月18日 SAG Mill Components. Once the basic operating conditions have been defined for the mill designer then, and only then, can he begin taking into account shell and head stresses and trunnion bearing sizes required to carry the load and to give the required openings for feeding and discharging the mills. Mill heads are key structural components

获取价格

SAG vs. AG Mills: Understanding the Key Differences

SAG mills use a combination of steel balls and rock particles as grinding media, while AG mills use only the ore itself. Both types of mills are used for grinding ore in mineral processing operations, but SAG mills are larger in size and can grind larger quantities of ore. AG mills, on the other hand, are smaller and are typically used for ...

获取价格

Operation Analysis of a SAG Mill under Different Conditions

semi-autogenous grinding process by dynamically modeling the SAG mill-pebble crusher loop to improve the SAG mill throughput. Cleary [8–10] studied the effect of rock particle shape on the dynamic filling and energy utilization in a SAG mill and analyzed the operation status of a SAG mill under different collision conditions through the coll ...

获取价格