vibrating screen manufacturer association sizing

SCREEN CAPACITY CALCULATION - VIBFEM

some obvious errors in the published tables. Most manufacturers use a modified version of the VSMA (Vibrating Screen Manufactures Association) formula to determine screen capacity. The twelve factors used in the formula below are based in large part on the

获取价格

McLanahan How To Size and Select a Vibrating Screen for an

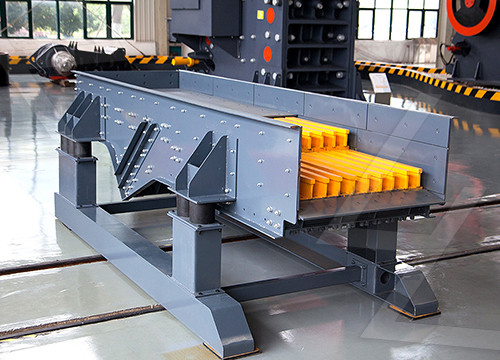

What Is A Vibrating screen?Types of Aggregate Vibrating ScreensHow to Select The Right Aggregate screenSizing Vibratory ScreensHow Many Decks Do I Need For My Vibratory screen?What Type of screen Media Is Best For My Vibratory screen?Vibratory Screens come in a variety of sizes. They can range from 4’ to 12’ wide and 6’ to 32’ long. The width of the screen determines the carrying capacity of the screen deck, while the length of the screen determines the overall efficiency of the screen. Typically, the length of the screen is 2.5 to 3 times the size of the width. Every manufactu...

Vibrating Screen Handbook - PDF - AEM

Product Description. Downloadable PDF, in black and white. Chapters cover the history of screening, types of screening media, selection of screen size and type, engineering data,

获取价格

进一步探索

Vibrating Screen Working Principle - Mineral Processing Vibrating Screen Working Principle Diagram - JXSC

VSMA Package - All 4 - PDF - AEM

Complete your vibrating screen reference library and order the entire set of vibrating screen booklets developed by AEM's Vibrating Screen Manufacturers Association

获取价格

How To Size and Select a Vibrating Screen for an Aggregate

2023年9月1日 Sizing Vibratory Screens. Vibratory Screens come in a variety of sizes. They can range from 4’ to 12’ wide and 6’ to 32’ long. The width of the screen determines

获取价格

Vibrating Screen Capacity Calculations - MEKA

The material velocity of a circular vibrating screen can be calculated from the corrected theoretical speed of the product formula written below. Example: Determine the material velocity of a screen vibrated at 900

获取价格

8 Questions to Ask When Sizing Screening Equipment

2019年10月3日 Many types of screening devices can be used for making particle size separation, including Vibrating Screens and Rotary Trommels. The right one for your application depends on your feed material and

获取价格

Dry Vibrating Screens for mining and industrial -

Find the ideal screens for your operation. Get Dry Vibrating Screens that are efficient, durable, easy to maintain and available in a wide range of sizes for all your mining

获取价格

TECHNICAL NOTES 4 VIBRATING SCREENS - 911 Metallurgist

half of the screen mesh size, the half-size factor will exceed unity and vice versa. K2 2P F(0.5h) 0.2 (4-5) The oversize factor K3 A screen can handle a greater tonnage of feed

获取价格

How to choose a vibrating screen manufacturer Haiside

2023年2月20日 Customization: Vibrating screens come in many different sizes, shapes, and designs, and a good manufacturer should be able to provide a wide range of

获取价格

vibrating screen manufacturer association sizing

Vibrating Screens Manufacturers. Vibrating Screens Manufacturers. Access customer reviews and keep up to date with product news articles. Whether you are looking for manufacturers of vibrating feeders, grizzly screens, parts feeders, or customized vibratory screens of every type, this is the resource for you.

获取价格

Syntron Material Handling - Vibrating Screens

Units range in size from a tiny, 3" wide pill de-duster to the massive 4' wide models used in heavy industry. We also offer electromechanical designs for high-tonnage screening of coarse materials. Models UP, VC, and NRM

获取价格

Vibratory Screen Manufacturer in India - Matech

Matech-Heavy Duty vibrating screen is our company for the coal industry developed large-scale screening. equipment, with large processing capacity, high screening efficiency. 2. Sieve body assembly using the most

获取价格

Large Vibrating Screen Design Maintenance - 911 Metallurgist

2018年10月16日 As larger vibrating screens are used, their size will exceed cost-effective shipping limits fully assembled. Screen manufacturers will join the ranks of other major equipment suppliers in on-site assembly and testing of these units. The incremental costs associated with these efforts must be considered in evaluating the plant construction and ...

获取价格

Vibrating screen manufacturer in India - Greenfield Tech Projects

We are manufacturer of vibrating screen in india. The vibrating screen separator is extensively utilised in a variety of industries, including mining, processing of crushed stone, food and beverage production, chemical production, and many others. Its main purpose is to divide materials into various sizes or grades in order to ensure efficient processing and

获取价格

Vibrating Screen Manufacturer from China - TSX Screen

As an experienced Vibrating screen manufacturer and factory in China, TSX Screen has been in the field of Vibrating screens for over 17 years. Our Vibrating Screen-related testing report can be provided. And will provide you with a qualified Mining Screen Products solution according to your project or Business request. 1.

获取价格

SWECO Vibrating Screens / Vibration Screens

Fusion Fusion Plus Screens. Fusion Screens are a revolutionary screen developed from a new technology that "fuses" the screen mesh to the tension ring. Fusion Screens have been designed to eliminate the use of adhesive, epoxy or silicone in screen manufacturing resulting in a unitary construction that minimizes the potential for contamination.

获取价格

Vibrating Screens - Kinergy - A Division of CPEG

Kinergy Driven Vibrating Screens. A “Dust-Tight” Screening Feeder to a Secondary Crusher. It is 11 ft. (3.2 m) wide, 40 ft. (12.2 m) long and 48″ (1.2 m) deep. Rated 2000 TPH of Limestone that screens the less than 6″ rock, it consumes 45 hp (34 kW). The adaptation of the patented Kinergy Drive System to Vibrating Screens is recognized ...

获取价格

How To Size and Select a Vibrating Screen for an Aggregate

2023年9月1日 Vibratory Screens come in a variety of sizes. They can range from 4’ to 12’ wide and 6’ to 32’ long. The width of the screen determines the carrying capacity of the screen deck, while the length of the screen determines the overall efficiency of the screen. Typically, the length of the screen is 2.5 to 3 times the size of the width.

获取价格

China Vibrating Screen, Cyclones, Wear-Resistant Screen

Shanghai Kminda Technology Co., Ltd: We're known as one of the most professional vibrating screen, cyclones, wear-resistant screen products, tailings dry discharge system, test sieve manufacturers and suppliers in China. Please rest assured to buy high quality products made in China here and get quotation from our factory. Good service and

获取价格

Vibrating Screen Manufacturers Association Formula

Vibrating Screen Manufacturer Association Sizing. 1determine what needs to be screened about the material weight tons per hour max in feed size product size wanted 2this will give you base data to do a mathematic vibrating screen sizing standard formula to determine the size of the vibrating screen needed in square feet to do the job.

获取价格

Vibratory Screens General Kinematics

Vibratory Screens. A leader in separation technology, General Kinematics screens can be found worldwide in a large variety of industries. From the separation of heavy ores, molten hot castings and sand, to paper products and everything in between. GK has made waves in the processing equipment industry using Two-Mass screening technology.

获取价格

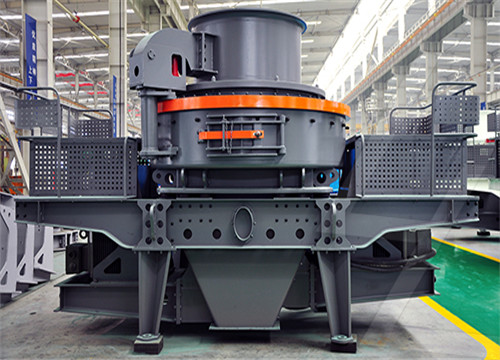

Top 10 Vibrating Screen Types Working Principle [How To

High-frequency vibrating screen is usually operated at an inclined angle 0°-25°, up to 45°, and the operating frequency range is 1500-7200r/m. 7. Grizzly Screen. Grizzly screen is often used for pre-screening before coarse and medium crushing of materials. The mesh size is generally >50mm, but sometimes <25mm.

获取价格

vibrating screen manufacturer association sizing

vibrating screen manufacturer association sizing. vibrating screens, vibrating screen, manufacturer, supplier The size of thevibratingscreenis decided as per the quantity of material to be sieved For sieving steel plate with punched whole known as Punching or The Vibratoryscreenmanufactured by Akashganga is designed using all mathematical

获取价格

Vibrating Screen Manufacturers Association Formula

Vibrating Screen Manufacturer Association Sizing. 1determine what needs to be screened about the material weight tons per hour max in feed size product size wanted 2this will give you base data to do a mathematic vibrating screen sizing standard formula to determine the size of the vibrating screen needed in square feet to do the job.

获取价格

Vibratory Screens General Kinematics

Vibratory Screens. A leader in separation technology, General Kinematics screens can be found worldwide in a large variety of industries. From the separation of heavy ores, molten hot castings and sand, to paper products and everything in between. GK has made waves in the processing equipment industry using Two-Mass screening technology.

获取价格

Top 10 Vibrating Screen Types Working Principle

High-frequency vibrating screen is usually operated at an inclined angle 0°-25°, up to 45°, and the operating frequency range is 1500-7200r/m. 7. Grizzly Screen. Grizzly screen is often used for pre-screening before

获取价格

vibrating screen manufacturer association sizing

vibrating screen manufacturer association sizing. vibrating screens, vibrating screen, manufacturer, supplier The size of thevibratingscreenis decided as per the quantity of material to be sieved For sieving steel plate with punched whole known as Punching or The Vibratoryscreenmanufactured by Akashganga is designed using all mathematical

获取价格

JOEST - South Africa Home

With more than 95 years of experience and over 750 people we have been growing to one of the largest manufacturers of vibrating equipment in the world. JOEST manufactures the biggest and widest vibrating screens in the world and offers full solutions especially for the mining, minerals, steel, foundry and recycling industries.

获取价格

Dry Vibrating Screens for mining and industrial -

A Dry Vibrating Screen is used to screen dry products like minerals and is useful in many processes including classification, sizing, scalping and recycling. Designed for your specific operation, our Dry Vibrating Screens come in a wide range of sizes ranging from 0.9m to 4.8m wide and up to 11.0m long.

获取价格

Vibrating Screen Capacity Calculations - MEKA

The material velocity of linearly vibrated screens can be obtained from the diagrams contained in appendix A-1. i = angle of incidence of the line of force in relation to the horizontal plane. e = eccentricity (mm) App = peak-to-peak (mm) = 2 x e. Example: Determine the material velocity of a screen that is vibrated at 900 RPM with a 12 mm ...

获取价格

Vibrating Screen Handbook - PDF - AEM

Product Description. Downloadable PDF, in black and white. Chapters cover the history of screening, types of screening media, selection of screen size and type, engineering data, problems and solutions, crusher circuits, technical data and more! 87 pages. 1998.

获取价格

Profile Wire and Polyurethane Screens - Elgin Separation

Elgin’s patented polyurethane screen systems can be used on almost all OEM vibrating screen manufacturers for sizing, rinsing and dewatering your product. We also offer hybrid screen decking available in woven wire, perforated plate and profile wire to maximize your screen’s efficiency. 12″ x 12″ Panels • 4 Pin and 6 Pin • Plug Free ...

获取价格

Basic concepts of vibrating screens: What they are, what they are

2023年8月2日 Also called simply screens, a vibrating screen is formed by a vibrant chassis that supports in its interior one or several surfaces or elements of screening. The screens serve to classify the different particles by size, starting from a bulk product in a continuous process. The inlet material (the raw product) advances from the part where

获取价格

The BIVITEC® Vibratory Screener Aggregates Equipment, Inc

Inclined Vibrating Screen Sizes. The BIVITEC ® is available in size ranges from 800mm x 3m (3’x10’) to 3000mm x 12m (10’x40’) 1,2,3 and 4 deck vibrating screens are available; Half Deck configuration allows multiple cuts in a single deck. Deck Options. BIVITEC® mesh sizes range from 100 mesh to 4”

获取价格

Tabor Vibrating Screens Elgin Separation Solutions

Tabor Vibrating Screens When you need reliable scalping, sizing, desliming, or rinsing of processed materials, trust Elgin’s product line of heavy-duty Tabor Vibrating Screens. Available in single, double, and triple deck configurations, Elgin’s vibrating screens deliver maximum durability with customizable features and accessories. Request A Quote

获取价格

How to successfully set up vibrating screens - Pit Quarry

2022年7月13日 Vibrating screen selection is based on several factors, including maximum tons per hour, gradation of the feed material, type and weight of material, desired size of separation, any surface moisture on material and any special operation requirements, including physical characteristics of the feed or product requirements. 3.

获取价格