copper smelting process slag beneficiation

Extraction and separation of copper and iron from copper

2022年9月25日 A large amount of copper smelting slag (CSS) containing valuable elements such as copper and iron is produced through smelting. With the increasing shortage of copper resources, the full recovery of valuable elements in CSS plays an

获取价格

The Phase Transition and Element Distribution of Copper Smelting

2023年2月22日 Slag cooling beneficiation, which uses the surface property differences of sulfide minerals and oxide minerals to enrich valuable elements in the slag

获取价格

A comprehensive review on the recovery of copper values from

2023年8月1日 The beneficiation of copper slag employing gravity concentration and froth flotation, with particular emphasis on different collector systems, has been reviewed

获取价格

进一步探索

(PDF) Beneficiation of copper slag - ResearchGateRecovery of metal values from copper slag and reuse of ...

Review on Comprehensive Recovery Valuable Metals and

2023年3月3日 Copper slag, a waste solid produced in the copper smelting process, is a high-quality secondary resource with huge output. The recycling and utilization of

获取价格

An efficient approach to utilize copper smelting slag: Separating ...

2023年12月1日 This study aimed to remove Cu, Zn, and Pb from copper slag during the chlorination process using experimental and thermodynamic analyses, and then reduce

获取价格

Enhancing the flotation recovery of copper minerals in smelter

Namibia Custom Smelters (NCS) process a range of copper concentrates in their three furnaces, namely; top submerged lance, copper converter and reverberatory furnaces, in

获取价格

Effect of Cooling Rate and Slag Modification on the Copper Matte

2020年7月31日 Abstract. The amount of copper flash smelting slag has increased during the recent years along with an increasing slag-to-metal ratio. During slag tapping, some

获取价格

Control of Copper Content in Flash Smelting Slag and

2023年1月11日 To determine slag properties and the factors influencing these properties for optimization of operating conditions in the copper flash smelting process, the composition and microstructures of the quenched

获取价格

Mineralogical and morphological factors affecting the separation

2021年1月5日 In this study, a combined reforming and reduction smelting of copper slag-steel slag was proposed to recover iron (Fe) from solid waste while lowering the environmental risks associated with the management of such waste. In this process, copper slag was mixed with steel tailing to sinter, and made into pellets after magnetic

获取价格

Sustainable and Comprehensive Utilization of Copper Slag: A

2023年4月21日 Metal Losses to the Slag in Smelting and Converting. 80% of the copper produced from ores worldwide originates from sulfide ores. The copper concentrate which results from flotation of the ore is typically smelted and converted to blister copper [].During smelting S and Fe are oxidized, where SiO 2 is added to form a liquid ferric or ferrous

获取价格

Characterization of copper slag for beneficiation of iron and copper

2021年4月14日 Our characterization results show that this BCL copper slag is a good secondary source of base metals, especially iron and copper. These results reveal that the elemental proportion of iron was around 35.4%. Literature states that an iron grade that is considered viable for economic beneficiation should be at least 25% and this slag has

获取价格

TENORM: Copper Mining and Production Wastes US EPA

2023年2月16日 Approximately 75 percent of the copper concentrate ends up as slag. The other layer, called "matte copper," consists of copper, iron sulfide and other metals. Converting: Finally, matte copper is converted into a copper-rich slag, which is then returned to the leaching process and separated from “blister copper," which is sent to

获取价格

Recovery of iron from copper slag by deep reduction and

2013年11月20日 Aiming at recovering iron from high-iron-content copper slag, this article introduced a combination technology of deep reduction and magnetic beneficiation, investigated the iron recovery efficiency and optimized the technical conditions. When coke powder with 86wt% fixed carbon was used as a reductant, iron was successfully

获取价格

Synergetic utilization of copper slag and ferruginous

2020年3月20日 Copper slag (CS) is a kind of hazardous waste generated during the copper-smelting process from copper sulfide concentrates (Potysz et al., 2017). About 2–3 tonnes of CS are generated per ton of produced blister copper (Potysz et al., 2017, Gbor et al., 2003). ... Beneficiation of high phosphorus limonite ore by sodium-salt

获取价格

Copper extraction - Wikipedia

Thus, the two factors that most affect the loss of copper to slag in the smelting stage are: matte grade; mass of slag. This means that there is a practical limit on how high the matte grade can be if the loss of copper to slag is to be minimized. Therefore, further stages of processing (converting and fire refining) are required.

获取价格

Comprehensive review on metallurgical recycling and cleaning of copper slag

2021年5月1日 Section snippets Generation and cleaning of copper slag. Copper pyrometallurgy, which is the primary method for the production of copper can be classified into different types, such as conventional copper smelting process (e.g. blast furnace smelting, reverberatory furnace smelting, and electric-furnace smelting), and modern

获取价格

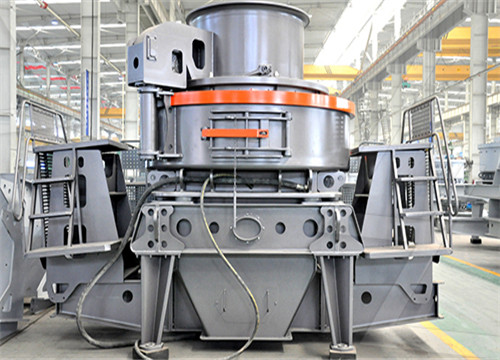

Improving Beneficiation of Copper and Iron from Copper Slag

2016年4月14日 In the paper, a new technology was developed to improve the beneficiation of copper and iron components from copper slag, by modifying the molten slag to promote the mineralization of valuable minerals and to induce the growth of mineral grains. Various parameters, including binary basicity, dosage of compound

获取价格

Smelting Metal: How It Works Metal Supermarkets

2023年6月28日 In addition to the desired metal, a by-product is also produced, termed slag. Slag is an impurity extracted from the metal ore itself. A brief history. Smelting has been used to make key tools and weapons as far back as ancient history. The technique dates back to 5000 BCE, when the first metal, copper, was smelted in the Middle East.

获取价格

Mineralogical and morphological factors affecting the

2021年1月5日 Separating copper and arsenic has always been a major problem in the copper slag flotation process, which influences copper slag utilization and the environmental safety. A comparative study of flash smelting furnace (FSF) slag and its flotation products (concentrate and tailing) reveals the factors

获取价格

Extraction and separation of copper and iron from copper smelting slag ...

2022年9月25日 In this work, a novel carbon-free smelting reduction process is proposed to recover valuable metals from molten copper slag, in which secondary aluminum dross is used as the reductant via co-modification with CaO and Na 2 O additions. The influence of Na 2 O addition on the metal recovery and slag properties under different CaO/SiO 2

获取价格

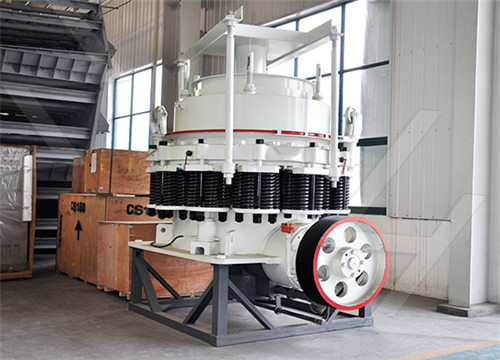

Crystallization Behavior of Copper Smelter Slag During

2015年5月19日 Copper slag is composed of iron silicate obtained by smelting copper concentrate and silica flux. One of the most important criteria for the utilization of this secondary resource is the recovery of iron from the slag matrix to decrease the volume of dumped slag. The molten oxidation process with crushing magnetic separation appears

获取价格

Minerals Free Full-Text Recovery of Iron from Copper Slag

2020年10月31日 The Fe3O4 and Fe2SiO4 in copper slag were successfully reduced to metallic iron by coal-based direct reduction. Under the best reduction conditions of 1300 °C reduction temperature, 30 min reduction time, 35 wt.% coal dosage, and 20 wt.% CaO dosage (0.75 binary basicity), the Fe grade of obtained iron concentration achieved

获取价格

Mineralogical and morphological factors affecting the

2021年1月5日 Separating copper and arsenic has always been a major problem in the copper slag flotation process, which influences copper slag utilization and the environmental safety. A comparative study of flash smelting furnace (FSF) slag and its flotation products (concentrate and tailing) reveals the factors

获取价格

Extraction and separation of copper and iron from copper smelting slag ...

2022年9月25日 In this work, a novel carbon-free smelting reduction process is proposed to recover valuable metals from molten copper slag, in which secondary aluminum dross is used as the reductant via co-modification with CaO and Na 2 O additions. The influence of Na 2 O addition on the metal recovery and slag properties under different CaO/SiO 2

获取价格

Crystallization Behavior of Copper Smelter Slag During

2015年5月19日 Copper slag is composed of iron silicate obtained by smelting copper concentrate and silica flux. One of the most important criteria for the utilization of this secondary resource is the recovery of iron from the slag matrix to decrease the volume of dumped slag. The molten oxidation process with crushing magnetic separation appears

获取价格

Minerals Free Full-Text Recovery of Iron from Copper Slag

2020年10月31日 The Fe3O4 and Fe2SiO4 in copper slag were successfully reduced to metallic iron by coal-based direct reduction. Under the best reduction conditions of 1300 °C reduction temperature, 30 min reduction time, 35 wt.% coal dosage, and 20 wt.% CaO dosage (0.75 binary basicity), the Fe grade of obtained iron concentration achieved

获取价格

Environmental and Socioeconomic Impact of Copper Slag—A

2021年12月3日 Numerous slags are produced as a second stream which is not desired in various metallurgical processes, e.g., copper slag (CS) from smelting and processing of copper ore [1,2].The main mineral ore source for copper is chalcopyrite (CuFeS 2), with the smelting process contributing approximately 80% of the global copper production from

获取价格

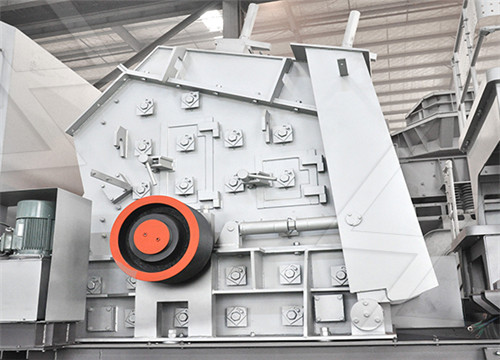

Simulation of flows of hazardous elements in copper smelting process ...

2022年12月20日 In the process of slag beneficiation, smelting slag and blowing slag are mixed proportionally, and copper concentrate and iron concentrate are obtained by a series of processes, such as slag cooling, crushing, and flotation. The selection rate of copper concentrate is about 10% and that of iron concentrate is about 30%.

获取价格

Comprehensive review on metallurgical recycling and cleaning of copper slag

2021年5月1日 The smelting process can be divided into three stages, namely decomposition of high-valence sulphide, oxidation of sulphide, and matte smelting and slagging reaction (Fig. 1).The efficiency of matte smelting and matte-slag separation, as well as the extent of copper losses to slag are mainly affected by the oxidation/reduction

获取价格

A Review of Comprehensive Utilization of Copper Slag of China

2022年2月2日 Full size image. The copper content of copper slag is 0.5–4.5% or even higher, which is much higher than the 0.2–0.3% mining grade of copper mines in China. The total iron content in copper slag is about 40%, which is significantly higher than the mineable grade of iron ore in China (TFe > 27%) [ 10 ].

获取价格

Energy and Environmental Profile of the U.S. Mining Industry 5

Smelting – Smelting involves the application of heat to a charge of copper ore concentrate, scrap, and flux to fuse the ore and allow the separation of copper from iron and other impurities. The smelter furnace produces two separate molten streams: copper-iron-sulfide matte and slag in addition to sulfur dioxide gas. The

获取价格

A comprehensive review on the recovery of copper values from copper slag

2023年8月1日 The beneficiation of copper slag employing gravity concentration and froth flotation, with particular emphasis on different collector systems, has been reviewed thoroughly. ... Copper metal is produced from these ores following a pyrometallurgical route of smelting or converting. This process results in the generation of vast quantities of ...

获取价格

Novel metallic Fe recovery from copper smelting slag by the

2023年7月1日 Since the copper smelting slag had recovered Cu by flotation, the Cu content in the copper smelting slag was relatively low, only 0.4%, which provided the possibility to recover Fe by the deep reduction method. Fe in the copper smelting slag existed as fayalite (Fe 2 SiO 4) mainly, some magnetite, accounting for 56.46% and

获取价格

Synergetic utilization of copper slag and ... - Semantic Scholar

2020年3月20日 Semantic Scholar extracted view of "Synergetic utilization of copper slag and ferruginous manganese ore via co-reduction followed by magnetic separation process" by De‐qing Zhu et al. ... a waste solid produced in the copper smelting process, is a high-quality secondary resource with huge output. ... beneficiation of Fe and Mn elements

获取价格

Characteristics of heavy metal pollution in soils of a typical copper ...

2021年10月1日 Slag beneficiation plant 9.85 4.96 <1 1.10 1.64 1.24 <1 <1 . ... Large amounts of heavy metals are confirmed to be released in the process of copper smelting (Zheng et al. 2021), and they pose a ...

获取价格

Comprehensive recovery of zinc, iron and copper from copper slag

2022年7月1日 1. Introduction. Copper slag has a dense structure and is chemically stable [[1], [2]].In the past, copper slag was regarded as industrial waste and directly dumped in the slag yard or utilized for building materials [[3], [4]].These treatments cause the loss of metal resources and pose not a high threat to the environment [5].Copper slag is an

获取价格